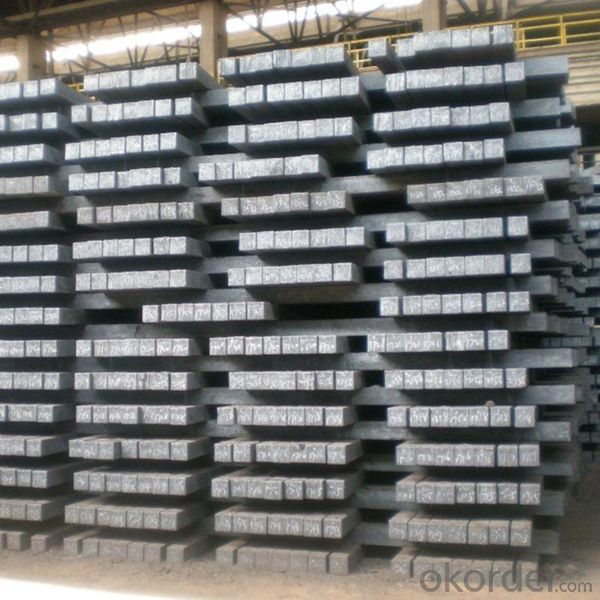

TK 440 superior hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

TK 440 superior hot rolled Carbon Steel Billets Square Billets

Size:30*30mm-150*150mm

Standard: GB,BS,ASTM

Grade: Q195/215/235/345/45#/3SP/5SP,ect

Application: Carbon structural steel, alloy structural steel, gear steel, spring steel,

bearing steel, etc.

Packaging Detail: exporting standard packing in mill or as request

Delivery Detail: within 15-30 days after receiving deposits or original LC

The Billets produced by the company can be broadly divided into three main types i.e.

1. M.S. Billets

2. CRS Billets

3. Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Square steel billet

1.Chemical Analysis | |||

Grade | Carbon(%) | Manganese(%) | Silicon(%) |

A | 0.14~0.22 | 0.30~0.65 | Max0.30 |

B | 0.12~0.20 | 0.37~0.67 | Max0.30 |

C | Max0.18 | 0.35~0.80 | Max0.30 |

D | Max0.17 | 0.35~0.80 | Max0.35 |

2.Mechnical Properties | |||

Tensile Strength(σb/Mpa) | Elongation(δ5/%) | ||

375---500 | ≥26(a≤16mm) | ||

3.basic information | |||

length | Spectfication(mm) | Material quality | Executive standard |

6m | 120*120 | Q235 | GB700-88 |

4.Trade information | |||

Price terms | Payment terms | Delivery time | Packing |

FOB/ CIF | T/T, L/C | Within 30 days | bundles |

- Q: How are steel billets inspected for internal and surface defects?

- Steel billets are inspected for internal and surface defects through various methods, including visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. Visual inspection involves examining the billets for any visible defects such as cracks, holes, or surface irregularities. Ultrasonic testing utilizes high-frequency sound waves to detect internal defects by analyzing the reflected waves. Magnetic particle inspection uses magnetic fields and iron particles to identify surface cracks or defects that may not be visible to the naked eye. Eddy current testing involves passing an electrical current through the billets to identify surface defects or inconsistencies in conductivity. These inspection techniques ensure the quality and integrity of steel billets for further processing.

- Q: What are the potential applications of steel billets in the chemical aftermarket?

- The chemical aftermarket offers a multitude of possibilities for the utilization of steel billets. One significant application of these billets lies in their role in the production of various chemical processing equipment. Reactors, heat exchangers, columns, and other critical components utilized in chemical plants can all be manufactured using steel billets. Furthermore, steel billets are also employed in the construction of storage tanks designed for the safe containment of chemicals. These tanks must possess qualities such as strength, durability, and resistance to corrosion, which can be achieved through the use of steel billets. Moreover, steel billets find their purpose in the fabrication of pipelines and piping systems used for the transportation of chemicals. Their exceptional strength, as well as their ability to withstand extreme temperatures and pressures, make them an ideal choice for constructing pipelines capable of handling corrosive and hazardous chemicals. Additionally, steel billets can be shaped and formed into various fittings and flanges, which serve as essential components in chemical systems. These fittings and flanges play a vital role in connecting different sections of piping, valves, and other equipment, thereby ensuring a secure and leak-free operation. To summarize, the potential applications of steel billets in the chemical aftermarket are vast and varied. From the manufacturing of chemical processing equipment to the construction of storage tanks, pipelines, and fittings, steel billets play a crucial role in guaranteeing the safe and efficient operation of chemical facilities.

- Q: Can steel billets be forged?

- Yes, steel billets can be forged. Forging is a common method used to shape metals into desired forms by applying compressive forces. Steel billets, which are semi-finished products in the form of rectangular bars, can undergo forging to transform them into various shapes such as bars, plates, or complex geometries. During the forging process, the steel billets are heated to a specific temperature to make them malleable, and then they are subjected to mechanical forces using hammers, presses, or other forging equipment. This enables the billets to be shaped and compressed, thereby improving their mechanical properties and imparting specific characteristics to meet desired requirements. Overall, forging steel billets is an important process in the production of various metal components and products.

- Q: How are steel billets used in the production of seamless pipes?

- Steel billets are an integral part of the production process for seamless pipes. Seamless pipes are pipes that are manufactured without any welding or seams, resulting in a smoother and more durable product. To produce seamless pipes, the first step is to melt steel in a furnace to create a molten metal. This molten steel is then poured into molds to form steel billets. Steel billets are solid, rectangular-shaped pieces of steel that serve as the raw material for seamless pipe production. Once the steel billets are formed, they are then heated to a specific temperature and pierced by a piercing mill. This process involves pushing a pointed mandrel through the center of the billet, creating a hollow tube or shell. The piercing mill applies both axial and radial forces to shape the billet into a seamless pipe. After piercing, the hollow tube is further elongated and reduced in diameter by a series of rolling mills. These mills use a combination of rotational and compressive forces to shape the billet into the desired seamless pipe size. The seamless pipe is continuously stretched and rolled until it reaches the desired length and diameter. The use of steel billets in the production of seamless pipes is crucial for several reasons. Firstly, the billets are made from high-quality steel, which ensures the strength and durability of the final product. Secondly, the uniformity and consistency of billets allow for precise shaping and seamless pipe dimensions. Lastly, the solid structure of billets enables them to withstand the intense forces and temperatures involved in the pipe manufacturing process. In conclusion, steel billets play a vital role in the production of seamless pipes. From being melted and molded into billets to being pierced, elongated, and rolled, these billets undergo a series of processes that transform them into high-quality seamless pipes. The use of steel billets ensures the integrity and reliability of seamless pipes, making them suitable for various industrial applications.

- Q: How are steel billets cleaned before further processing?

- Steel billets are typically cleaned before further processing through a process known as descaling. This involves removing any mill scale or oxides on the surface of the billets using techniques such as shot blasting, pickling, or high-pressure water jetting. The cleaned billets are then ready for subsequent processing steps such as hot rolling or forging.

- Q: What are the potential applications of steel billets in the electronics industry?

- The electronics industry can benefit from the potential applications of steel billets. While steel is not traditionally associated with this sector, advancements in technology have allowed for its use in various ways. One potential application is using steel billets to produce electronic enclosures. These enclosures offer superior durability and protection for electronic components. They can withstand harsh environments, provide electromagnetic shielding, and prevent damage from impacts or accidents. Manufacturers have the flexibility to shape and form steel billets into different enclosure designs to meet specific requirements. Another application is in manufacturing connectors and terminals. Steel billets can be machined and formed into intricate shapes and sizes, making them suitable for creating reliable and strong connectors. Steel connectors offer excellent conductivity, ensuring efficient and secure connections between electronic components. Additionally, steel's resistance to corrosion makes it a viable option for connectors exposed to moisture or other harsh conditions. Steel billets can also be used to produce high-strength structural components in electronic devices. These components, such as brackets, frames, or supports, require materials with exceptional strength and rigidity. Steel billets, with their high strength-to-weight ratio, provide the necessary structural integrity and stability. Their robustness ensures the longevity and reliability of electronic devices, especially those subjected to heavy loads or vibrations. Furthermore, steel billets can find applications in manufacturing heat sinks. Heat sinks are crucial for dissipating heat generated by electronic components and preventing overheating. Steel, with its excellent thermal conductivity, efficiently transfers heat away from sensitive electronic parts. By shaping steel billets into heat sink designs, manufacturers can create effective cooling systems that enhance the performance and longevity of electronic devices. In conclusion, steel billets have numerous potential applications in the electronics industry. From electronic enclosures to connectors, structural components, and heat sinks, steel's durability, conductivity, and thermal properties make it a valuable material for electronic device production. As technology continues to advance, the use of steel billets in the electronics industry is expected to expand further, offering more innovative solutions for electronic manufacturers.

- Q: Can steel billets be used in the production of mining equipment?

- Steel billets, being semi-finished products, find extensive use in the manufacturing industry for the production of mining equipment. The robustness and durability of steel make it an ideal material for mining equipment, which often operates in tough and demanding conditions. By processing and shaping steel billets, essential components like gears, shafts, frames, and buckets can be created, all of which are vital for mining equipment. Moreover, steel billets can be easily welded, machined, and heat-treated to meet the specific requirements and standards of mining equipment. Therefore, steel billets play a critical role in ensuring the strength and dependability necessary for safe and efficient mining operations.

- Q: What are the advantages of using steel billets in construction?

- There are several advantages of using steel billets in construction: 1. Strength and Durability: Steel billets are known for their high strength and durability, making them ideal for construction purposes. They can withstand heavy loads and extreme weather conditions, ensuring the longevity and stability of the structure. 2. Versatility: Steel billets can be molded and shaped into various forms, allowing for flexibility in design and construction. This versatility makes them suitable for a wide range of applications, from beams and columns to framing and foundations. 3. Cost-effectiveness: Despite the initial cost of steel billets being higher than other construction materials, their long-term benefits outweigh the investment. Steel is low maintenance, doesn't require frequent repairs or replacements, and offers excellent fire resistance, reducing insurance costs. 4. Sustainability: Steel is a highly sustainable material due to its recyclability. Steel billets can be recycled and reused without losing their properties, reducing the demand for virgin materials and minimizing environmental impact. 5. Speed of construction: Steel billets are pre-fabricated, meaning they are manufactured off-site and then transported to the construction site. This significantly reduces construction time and allows for faster completion of projects. 6. Resistance to pests and rot: Unlike wood, steel billets are not susceptible to termites, pests, or rot. This eliminates the need for chemical treatments or regular inspections, saving both time and money. 7. Design flexibility: Steel billets offer a wide range of design possibilities, enabling architects and engineers to create unique and aesthetically pleasing structures. The ability to span large distances without the need for additional support columns allows for open floor plans and creative architectural designs. In summary, the advantages of using steel billets in construction include their strength, durability, versatility, cost-effectiveness, sustainability, speed of construction, resistance to pests and rot, and design flexibility. These factors make steel billets an excellent choice for various construction projects, ensuring sturdy and long-lasting structures.

- Q: Can steel billets be used in the production of energy infrastructure?

- Certainly, energy infrastructure can be produced using steel billets. Steel is extensively utilized in the construction of various energy infrastructure components, including power plants, transmission towers, pipelines, and wind turbine towers. By further processing and shaping semi-finished steel products known as steel billets, the required forms for these infrastructure projects can be achieved. The durability, strength, and versatility of steel make it well-suited for withstanding the demanding conditions and heavy loads associated with energy infrastructure. Moreover, steel provides excellent resistance against corrosion, which is of utmost importance for infrastructure exposed to the elements. In summary, the use of steel billets plays a crucial role in the production of energy infrastructure, ensuring the reliable and efficient generation, transmission, and distribution of energy.

- Q: Can steel billets be used in the production of bicycles?

- Yes, steel billets can be used in the production of bicycles. Steel billets are semi-finished products made from steel and can be further processed into various shapes and sizes. In the case of bicycles, steel billets can be shaped and formed into different bicycle components such as frames, forks, handlebars, and other structural parts. Steel is a popular choice for bicycle production due to its strength, durability, and affordability. It provides excellent stiffness, stability, and resistance to deformation, making it suitable for various types of bicycles, including road bikes, mountain bikes, and hybrid bikes. Additionally, steel can be easily welded, allowing for customization and repairability of bicycle frames.

Send your message to us

TK 440 superior hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords