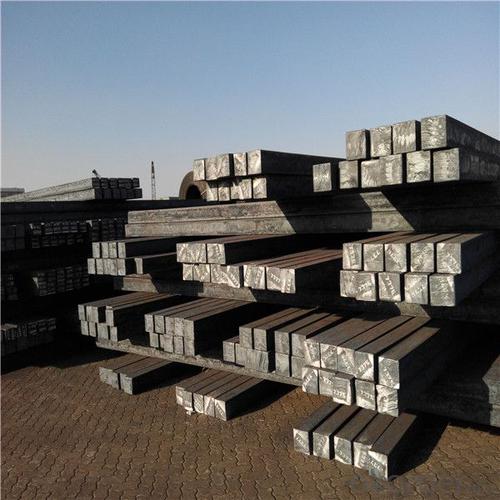

Hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16021 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet :

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

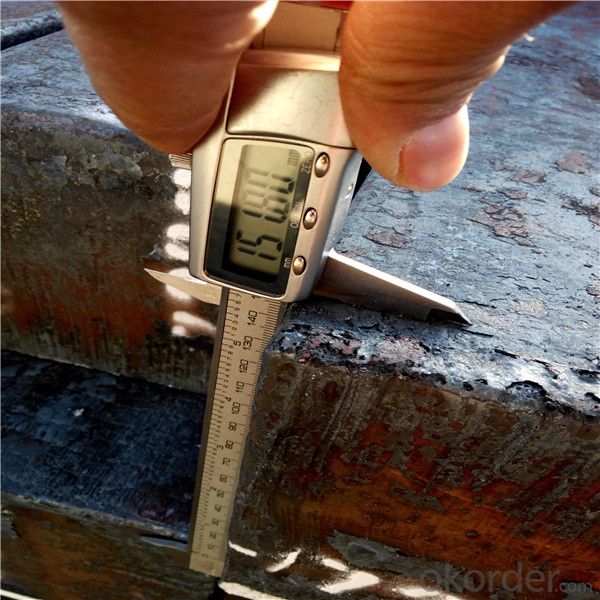

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the different types of forging processes used for shaping steel billets?

- There are several types of forging processes used for shaping steel billets. Some common ones include open-die forging, closed-die forging, impression-die forging, and seamless rolled ring forging. Each process has its unique characteristics and is suitable for specific applications.

- Q: How are steel billets used in the manufacturing of railway equipment?

- Steel billets are used in the manufacturing of railway equipment as they are heated and then shaped into various components such as rails, wheels, axles, and couplings. These billets serve as the raw material that undergoes further processing, including cutting, bending, and welding, to create the final products used in the construction and maintenance of railway systems.

- Q: How are steel billets shaped into other forms?

- A process known as hot rolling is used to transform steel billets into different forms. This process involves feeding the steel billet through heated rollers, which compress and mold it into the desired shape. To begin, the steel billet is heated to a high temperature in a furnace. This heat treatment makes the steel more malleable and easier to shape. Once the billet has reached the desired temperature, it is then sent into a rolling mill. Within the rolling mill, the billet undergoes a series of passes through rollers that apply pressure and force to shape the steel. These rollers come in various shapes and sizes depending on the desired outcome. As the billet passes through the rollers, it gradually takes on the desired form, such as sheets, bars, or beams. The rolling process not only shapes the steel but also improves its mechanical properties. It refines the grain structure, enhances strength and toughness, and eliminates any internal defects. This makes the steel more suitable for a range of applications, including construction, automotive, and machinery. Following the hot rolling process, the steel often undergoes additional processing through cold rolling. This involves passing the steel through cold rollers to further refine its surface finish and dimensions. Additionally, secondary operations like cutting, bending, and welding may be carried out to further shape the steel into the desired end product. In conclusion, hot rolling plays a vital role in transforming steel billets into various forms. It enables the production of a wide range of steel products, each with its own unique shape, size, and mechanical properties. This helps meet the diverse needs of industries worldwide.

- Q: How are steel billets heated for rolling?

- Steel billets are heated for rolling using a process called induction heating, where an electric current is passed through the billets to generate heat. This method allows for precise and efficient heating, ensuring uniform temperature distribution throughout the billets.

- Q: What are the different surface treatment options for steel billets?

- There are several different surface treatment options available for steel billets, depending on the specific requirements and applications. Some of the common surface treatment methods for steel billets include: 1. Pickling: This process involves immersing the steel billets in an acid solution to remove any scales or impurities on the surface. Pickling helps to improve the surface finish and prepare the steel for further treatment or processing. 2. Shot blasting: Shot blasting is a mechanical process that involves propelling small steel shots at high velocity onto the surface of the billets. This treatment helps to remove rust, scales, and other contaminants, resulting in a clean and smooth surface finish. 3. Phosphating: Phosphating is a chemical treatment method that involves applying a phosphate coating onto the steel billets' surface. This process helps to improve corrosion resistance, enhance paint adhesion, and provide a uniform surface for subsequent treatments. 4. Galvanizing: Galvanizing is a popular surface treatment option where a layer of zinc is applied to the steel billets' surface through a hot-dip or electroplating process. This treatment provides excellent corrosion resistance, making it suitable for outdoor applications. 5. Coating: Steel billets can be coated with various materials, such as epoxy, polyurethane, or powder coatings, to enhance their appearance, provide additional corrosion protection, or improve resistance to wear and tear. 6. Passivation: Passivation is a chemical treatment process that aims to remove any free iron or iron oxide from the steel billets' surface and form a protective oxide layer. This treatment helps to increase corrosion resistance and improve the billets' overall performance. It is important to consider the specific requirements and intended use of the steel billets when selecting the appropriate surface treatment method. Factors such as corrosion resistance, appearance, adhesion, and wear resistance should be taken into account to ensure the desired performance and longevity of the steel billets.

- Q: What are the different types of steel billets used in the manufacturing industry?

- There are several different types of steel billets used in the manufacturing industry, including carbon steel billets, alloy steel billets, stainless steel billets, and tool steel billets. Each type of billet has its own unique composition and properties, making them suitable for various applications in industries such as construction, automotive, and aerospace.

- Q: What are the different methods of steel billet casting?

- There are several methods of steel billet casting, including continuous casting, ingot casting, and direct casting. Continuous casting is the most common method, where molten steel is poured into a water-cooled mold and solidifies into a continuous strand. Ingot casting involves pouring molten steel into individual molds to create solid metal ingots. Direct casting, also known as hot top casting, involves pouring molten steel directly into a single mold without using any intermediate steps. Each method has its own advantages and is used based on the specific requirements of the steel billet.

- Q: How are steel billets used in the manufacturing of construction materials?

- The manufacturing of construction materials relies heavily on steel billets, which are a necessary raw material. These semi-finished forms of steel serve as the initial stage for various construction products, including rebars, beams, columns, and plates. During the production process, steel billets undergo heating and are then passed through a series of rolling mills to achieve the desired shape. For example, when producing rebars, the billet is heated and rolled into long, slim bars of different diameters. These rebars are commonly used in construction to reinforce concrete structures, ensuring their durability and strength. Likewise, steel billets are utilized in the creation of beams, columns, and plates, which are essential elements in building construction. Beams provide structural support, while columns bear the weight of the structure and transmit loads to the foundation. Plates, on the other hand, find applications in flooring, walls, and roofing. The utilization of steel billets in construction materials offers numerous benefits. Steel, renowned for its high strength-to-weight ratio, provides exceptional structural integrity, resulting in more efficient and cost-effective construction. Furthermore, steel is highly ductile, allowing it to be easily shaped and molded into various forms, enabling versatility in design and construction. Additionally, steel is a durable material that exhibits excellent resistance to environmental factors like corrosion and fire. Consequently, steel construction materials have a long lifespan and are suitable for a wide range of applications, including high-rise buildings, bridges, and infrastructure projects. In conclusion, steel billets play a vital role in the manufacturing of construction materials. By being transformed into rebars, beams, columns, and plates, these billets provide the necessary strength, durability, and versatility required in the construction industry.

- Q: What is the role of steel billets in the manufacturing of automotive body panels?

- The manufacturing of automotive body panels heavily relies on steel billets, which are essential semi-finished metal products. These billets serve as the initial material for creating various components that compose a car's body. The primary rationale behind using steel billets in this process lies in their exceptional strength and durability. Automotive body panels need to endure different external forces and impacts, such as collisions, extreme weather conditions, and everyday wear and tear. Steel, being a robust and inflexible material, provides the necessary structural integrity to ensure the vehicle's safety and longevity. Furthermore, steel billets offer versatility in terms of design and customization. They can be effortlessly molded and shaped into different forms and sizes, enabling manufacturers to produce body panels with precise specifications. This adaptability allows for the creation of diverse car models with unique designs that meet the varied demands of consumers. Additionally, steel billets are favored for their cost-effectiveness. Steel is a widely available and relatively inexpensive material, making it a practical option for large-scale production. Moreover, its recyclability further reduces production costs and lessens environmental impact. In conclusion, the role of steel billets in the manufacturing of automotive body panels is of utmost importance. They provide the necessary strength, durability, versatility, and cost-effectiveness required for producing high-quality and dependable car bodies.

- Q: What are the potential applications of steel billets in the defense sector?

- Steel billets have a range of potential applications in the defense sector, including the manufacturing of armored vehicles, tanks, and naval vessels. They can also be used for constructing military infrastructure, such as bunkers, fortifications, and barriers. Additionally, steel billets can be utilized in the production of various weapons and ammunition, such as artillery shells and components for firearms. The strength, durability, and versatility of steel make it an essential material for various defense applications.

Send your message to us

Hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16021 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords