Carbon Steel Billets High Quality Square Billets for construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Carbon Steel Billets High Quality Square Billets for construction

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Carbon Steel Billets High Quality Square Billets for construction

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Carbon Steel Billets High Quality Square Billets for construction

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Carbon Steel Billets High Quality Square Billets for construction

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

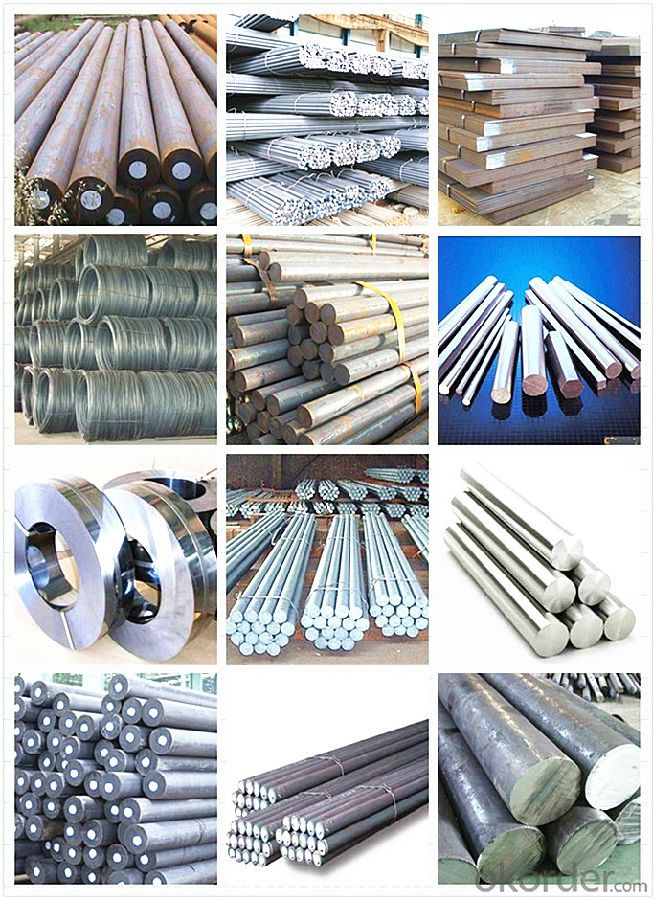

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How are steel billets used in the production of automotive fuel systems?

- Steel billets are used in the production of automotive fuel systems as they are melted and shaped into various components such as fuel tanks, fuel rails, and fuel pump housings. These billets provide the necessary strength, durability, and corrosion resistance required for these critical components, ensuring the safe storage and delivery of fuel in vehicles.

- Q: Can steel billets be used for marine applications?

- Indeed, the utilization of steel billets in marine applications is possible. Frequently, steel billets serve as a fundamental resource for diverse marine components and structures. Given their remarkable strength and durability, steel billets are ideal for marine applications necessitating resistance to corrosion, impact, and harsh environmental conditions. Ship hulls, propeller shafts, marine pipelines, offshore platforms, and other marine structures can all be manufactured using steel billets. Moreover, steel billets can undergo additional processing and shaping to meet precise specifications for marine applications.

- Q: What are the potential applications of steel billets in the agricultural aftermarket?

- Steel billets have a wide range of potential applications in the agricultural aftermarket. One of the key uses of steel billets in this industry is for the manufacturing of agricultural machinery and equipment. Steel billets are commonly used to fabricate components such as plows, cultivators, seeders, and harvesting equipment. The agricultural industry requires durable and robust machinery that can withstand the harsh conditions of farming operations. Steel billets provide the necessary strength and toughness to withstand the demanding tasks involved in agriculture, such as tilling the soil or harvesting crops. The high-strength properties of steel billets make them ideal for withstanding heavy loads and rough terrain. Additionally, steel billets can be used for constructing storage and handling structures in the agricultural sector. Steel buildings and structures are highly resistant to weathering, pests, and fire, making them suitable for storing grain, livestock, and other agricultural products. Steel billets can be used to fabricate the main framework of these structures, ensuring their durability and longevity. Another potential application of steel billets in the agricultural aftermarket is for the production of fencing and livestock handling equipment. Steel fencing is commonly used in agricultural settings to secure boundaries, contain livestock, and protect crops from animals. Steel billets can be shaped and welded to create strong and reliable fencing materials that can withstand the test of time. Furthermore, steel billets can be utilized in the manufacturing of irrigation systems and water management equipment. Agricultural operations often require efficient irrigation systems to ensure proper water distribution to crops. Steel billets can be used to fabricate pipes, valves, and other components that are critical for irrigation systems, providing a durable and long-lasting solution. In summary, steel billets have numerous potential applications in the agricultural aftermarket. From manufacturing machinery and equipment to constructing storage structures, fencing, and irrigation systems, steel billets offer the strength, durability, and reliability required in the demanding agricultural industry.

- Q: How do steel billets contribute to the manufacturing of kitchen appliances?

- Steel billets are used as raw materials in the manufacturing of kitchen appliances because of their excellent strength, durability, and heat resistance properties. These billets are melted and formed into various shapes, such as sheets or rods, which are then used to create the structures and components of kitchen appliances. Steel billets ensure that kitchen appliances can withstand heavy use, high temperatures, and retain their structural integrity, making them an essential component in the manufacturing process.

- Q: What are the dimensions of a typical steel billet?

- The dimensions of a typical steel billet can vary depending on its intended use and the specific manufacturing process. However, in general, steel billets are rectangular in shape and have dimensions that range from 100mm to 300mm in width, 100mm to 400mm in height, and 6m to 12m in length. These dimensions allow for ease of handling and transportation, as well as flexibility in shaping and forming the steel billet into various end products such as bars, rods, or sheets. It is important to note that these dimensions are not fixed and can be customized based on the specific requirements of the production process or the customer's needs.

- Q: What is the role of steel billets in the construction of offshore platforms?

- The construction of offshore platforms heavily relies on steel billets, as they play an essential role in this process. Offshore platforms are enormous structures situated in the open sea, used for extracting oil or gas from beneath the ocean floor. Due to the demanding environmental conditions and the paramount importance of safety and durability, steel billets are extensively utilized in their construction. One of the key functions of steel billets is to serve as the primary material for fabricating different components of offshore platforms. Billets are large, semi-finished steel products typically employed as starting materials in the production of other steel products. They are cast into specific shapes, often square or rectangular, and possess a solid cross-section. Offshore platforms necessitate steel with exceptional strength, corrosion resistance, and impact toughness to withstand the challenging conditions they face, including strong waves, harsh weather, and extreme temperatures. Steel billets are frequently made from high-strength alloyed steels, providing superior mechanical properties and corrosion resistance. These billets are further processed to manufacture various structural elements of offshore platforms, such as beams, columns, braces, and other support structures. These components must have the ability to bear the weight of the platform itself, as well as endure the forces generated by ocean waves, wind, and the extraction process. Additionally, steel billets are also utilized in the production of pipes and tubes, which are crucial for transporting oil and gas from beneath the seabed to the platform or to the shore. These pipes must possess strength, durability, and corrosion resistance to ensure the secure and efficient flow of hydrocarbons. To summarize, steel billets act as the fundamental building blocks for constructing offshore platforms. They provide the raw material necessary for fabricating various structural components, guaranteeing the strength, durability, and safety of these massive structures in the challenging offshore environment.

- Q: What are the different types of defects in steel billets?

- Steel billets, which are semi-finished steel products used in various manufacturing processes, can experience different types of defects. These defects can arise during production or handling and can impact the overall quality, mechanical properties, and structural integrity of the billets. Some common defect types found in steel billets include: 1. Surface defects: These defects are visible on the outer surface of the billet and can include scratches, cracks, pits, or scale. Improper handling, storage, transportation, or manufacturing processes can cause surface defects. 2. Internal defects: These defects occur within the cross-section of the billet and are not visible to the naked eye. They can include blowholes, inclusions, segregations, or voids. Impurities in raw materials, inadequate casting or solidification processes, or insufficient quality control measures can lead to internal defects. 3. Dimensional defects: These defects refer to variations in the billet's dimensions compared to specified requirements. They can involve deviations in length, width, or thickness beyond acceptable tolerances. Improper cutting, rolling, or cooling processes during billet production can cause dimensional defects. 4. Chemical composition defects: These defects occur when the steel billet does not meet the required chemical composition specifications. Impurities in raw materials, inadequate mixing or alloying processes, or insufficient quality control during production can lead to chemical composition defects. 5. Mechanical defects: These defects impact the mechanical properties of the steel billet, such as strength, toughness, or ductility. Improper heat treatment, quenching, or tempering processes, as well as inadequate quality control during manufacturing, can result in mechanical defects. Detecting and minimizing these defects is crucial as they can negatively affect the performance and reliability of the final steel products made from the billets. Implementing quality control measures, including regular inspection and testing, can help identify and rectify any defects in steel billets, ensuring the production of high-quality finished products.

- Q: Are steel billets recyclable?

- Steel billets can indeed be recycled. As one of the most widely recycled materials globally, steel has a well-established and remarkably efficient recycling process for its billets. When these billets reach the end of their usefulness, they can be melted and repurposed to create new steel products. By engaging in this recycling process, we not only conserve precious natural resources but also decrease energy consumption and minimize our environmental footprint. Moreover, recycling steel billets aids in diminishing landfill waste while supporting the circular economy and promoting the sustainable utilization of resources.

- Q: What are the different types of steel billet casting defects?

- During the casting process of steel billets, various types of defects may occur, impacting the final product's quality and performance. These defects can range in severity and have different effects on the billets. Common defects include: 1. Insufficient feeding of liquid metal during solidification can cause shrinkage defects, resulting in voids or cavities within the billet. This weakens the billet's strength and may lead to failure under stress. 2. Porosity defects are characterized by the presence of small gas bubbles or voids within the billet. They reduce density, weaken the material, and affect mechanical properties such as tensile strength and ductility. 3. Foreign substances, such as non-metallic particles, oxides, or impurities, can become trapped within the billet, resulting in inclusion defects. These negatively impact mechanical properties like ductility and increase brittleness. 4. Surface defects, like cracks, scabs, or uneven surfaces, can occur during casting, affecting the appearance and structural integrity of the billet. 5. Uneven distribution of alloying elements within the billet leads to segregation defects. This inconsistency in composition affects mechanical properties and overall performance. 6. During solidification, thermal stresses can cause cracks known as hot tears, weakening the billet and reducing its strength under stress. 7. When the liquid metal fails to completely fill the mold cavity, misruns occur, resulting in incomplete billets. This defect leads to reduced dimensions, poor surface finish, and compromised mechanical properties. Addressing and identifying these defects is crucial to ensure the production of high-quality and reliable steel products. Techniques such as proper mold design, controlling casting parameters, and process optimization can be employed to minimize these defects and improve the overall quality of the billet.

- Q: What are the main challenges in the handling of steel billets during production?

- The production of steel billets poses various challenges that must be addressed in order to achieve a streamlined and effective manufacturing process. Weight and size are major obstacles to consider when working with steel billets. These billets can be quite hefty, ranging from a few hundred kilograms to several tons, depending on their dimensions. As a result, lifting and moving them within the production facility can be difficult. The safe handling of these heavy loads necessitates the use of specialized equipment, such as cranes and forklifts. Another challenge lies in the potential for damage during the handling of steel billets. They are typically transported and stored in stacks or bundles, and improper handling techniques or inadequate protection can result in deformation, scratches, or even breakage of the billets. These damages can negatively impact the quality of the final product, leading to increased scrap rates and production costs. Furthermore, maintaining precise temperature control is crucial when working with steel billets. Steel is highly sensitive to temperature changes, and the billets must be kept within specific temperature ranges to prevent distortion or metallurgical issues. Careful attention must be paid when transferring billets between different areas of the production facility to ensure consistent temperatures. Proper inventory management and tracking also present challenges in the handling of billets. Steel billets are often stored in large warehouses or outdoor yards, and keeping track of their location, quantity, and quality can be complex. Efficient inventory management systems, such as barcoding or RFID tagging, are essential to minimize errors and facilitate the retrieval of the necessary billets for production. Lastly, safety is a significant concern when handling steel billets. The weight of the billets and the potential for injury make it imperative to adhere to strict safety protocols. Operators must receive proper training on the use of equipment, such as cranes and forklifts, and wear appropriate personal protective equipment (PPE) to prevent accidents or injuries. In conclusion, the handling of steel billets during production presents challenges related to weight, potential damage, temperature control, inventory management, and safety. Overcoming these challenges necessitates investments in specialized equipment, training, and efficient processes to ensure a smooth and successful production operation.

Send your message to us

Carbon Steel Billets High Quality Square Billets for construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords