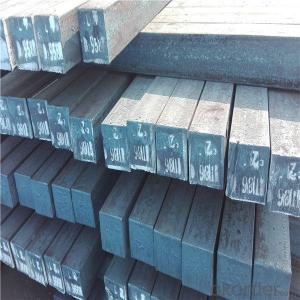

Hot Rolled Steel Square Steel Billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Billet at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

.

Product Advantages:

OKorder's Steel Billet are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

M.S. Billets

CRS Billets

Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

The following are the sizes of Billets available with Shyam Steel Industries Ltd.:

100 X 100

120x120

150 X 150

Physical Properties:

Description

As per IS 2830

Shyam Billets

Bend (max.) 5 mm per meter >= 5 mm per meter

Carbon (max.) 3mm per meter >= 3 mm per meter

Length 3 mt - 13 mt 3 mt - 9 mt

Chemical Properties:

Ladle Analysis:

Designation

Carbon

Manganese

C15 0.12-0.18 0.30-0.60

C18 0.15-0.21 0.30-0.60

C20 0.17-0.23 0.30-0.60

C15 MMn 0.12-0.18 0.60-1.00

C18 MMn 0.15-0.21 0.60-1.00

C20 MMn 0.17-0.23 0.60-1.00

C15 HMn 0.12-0.18 1.00-1.50

C18 HMn 0.15-0.21 1.00-1.50

C20 HMn

0.17-0.23 1.00-1.50

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How do steel products contribute to the construction of dams and reservoirs?

- Steel products play a vital role in the construction of dams and reservoirs due to their durability, strength, and versatility. Steel is used extensively in the structural components of dams, such as gates, spillways, and penstocks, as it can withstand high pressures and heavy loads. Additionally, steel reinforcement bars are incorporated into the concrete to enhance its tensile strength, ensuring the structure's stability. Steel sheets and plates are also employed for lining tunnels and creating watertight barriers. Overall, steel products provide the necessary strength and reliability required for the successful construction and long-term functionality of dams and reservoirs.

- Q: How is steel made and processed to create various steel products?

- Steel is made through a process called steelmaking, which involves melting iron ore in a furnace and adding various alloying elements to enhance its properties. Once the molten steel is formed, it is then processed through techniques like casting, rolling, forging, or extrusion to create a wide range of steel products such as sheets, bars, pipes, or structural components. These processes help shape the steel into the desired form, size, and strength, ensuring that it can be used in various industries like construction, automotive, or manufacturing.

- Q: How is steel used in the construction of stadiums and arenas?

- Steel is used extensively in the construction of stadiums and arenas due to its strength, durability, and versatility. It is commonly used to create the structural framework of these large structures, supporting the weight of the roof, seating areas, and other components. Steel is also used for the fabrication of beams, columns, and trusses, providing the necessary stability and load-bearing capacity. Additionally, steel is utilized for the construction of stairs, walkways, and various architectural features. Overall, steel plays a crucial role in ensuring the safety, longevity, and aesthetic appeal of stadiums and arenas.

- Q: How is steel wire galvanized for fencing applications?

- Steel wire is galvanized for fencing applications by immersing it in a bath of molten zinc. This process, known as hot-dip galvanizing, creates a protective coating on the wire. The wire is first cleaned to remove any impurities, then dipped into the zinc bath, ensuring complete coverage. The zinc coating prevents corrosion and extends the lifespan of the wire, making it suitable for fencing applications.

- Q: How is steel used in the production of elevator systems?

- Steel is a crucial material in the production of elevator systems as it is used for constructing the elevator car, the support structure, and the guide rails, ensuring durability, strength, and safety for the entire system.

- Q: What are the advantages of using steel in the manufacturing of solar panels?

- There are several advantages of using steel in the manufacturing of solar panels. Firstly, steel is a strong and durable material, which ensures the longevity and reliability of the solar panels. Secondly, steel is readily available and cost-effective, making it an economical choice for mass production. Additionally, steel is highly recyclable, reducing the environmental impact of solar panel production. Lastly, steel's high thermal conductivity allows for efficient heat dissipation, preventing damage to the solar cells and ensuring optimal performance.

- Q: What are the different types of heat treatment processes for steel?

- There are several different types of heat treatment processes for steel, including annealing, normalizing, quenching, tempering, and case hardening.

- Q: What are the common types of steel products used in the pet training and behavior industry?

- The common types of steel products used in the pet training and behavior industry include metal crates and kennels, leash hooks and hangers, training collars, prong collars, and various types of training and exercise equipment such as agility tunnels, jumps, and weave poles.

- Q: What are the common uses of steel angles?

- Steel angles are commonly used in construction and engineering projects for various purposes. They are used as structural supports, providing stability and strength to buildings, bridges, and other structures. Steel angles are also used as framing members in the construction of frames, shelves, and racks. Additionally, they are used in the manufacturing of machinery and equipment, as well as in the fabrication of furniture and fixtures. Overall, steel angles are versatile and widely utilized due to their durability, load-bearing capacity, and ease of installation.

- Q: What are the common types of steel products used in the textile industry?

- Some common types of steel products used in the textile industry include steel wires, steel pins, steel needles, and steel hooks. These products are used for various purposes such as fabric weaving, sewing, fastening, and hanging materials in textile machinery.

Send your message to us

Hot Rolled Steel Square Steel Billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords