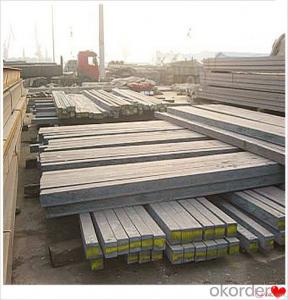

Carbon Steel Billets Square Billets hot sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16250 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the factors that determine the lifespan of steel billets?

- The lifespan of steel billets is influenced by several factors. Firstly, the quality of the steel used in the production of billets is critical. Steel with high levels of impurities or inconsistent composition may have a shorter lifespan. The manufacturing process also plays a significant role. If the steel billets are not properly heated, cooled, or rolled, they may develop internal stresses or defects that can lead to premature failure. Environmental factors also impact the lifespan of steel billets. Exposure to corrosive substances, such as chemicals or moisture, can result in corrosion and degradation of the steel. Additionally, extreme temperatures can cause thermal expansion and contraction, leading to fatigue or cracking of the billets over time. The handling and storage of steel billets are also important factors. If they are mishandled, dropped, or subjected to excessive impact, it can lead to deformation or microstructural changes that reduce their lifespan. Proper storage conditions, including protection from moisture, direct sunlight, and extreme temperature fluctuations, can help preserve the integrity of the billets. Regular maintenance and inspection also contribute to determining the lifespan of steel billets. Timely detection and repair of any defects or damages can prevent further deterioration and extend their lifespan. In summary, the quality of the steel, manufacturing process, environmental conditions, handling and storage practices, as well as maintenance and inspections, all play crucial roles in determining the lifespan of steel billets.

- Q: What is the typical density of a steel billet?

- The density of a steel billet is contingent upon the particular type of steel employed. Nonetheless, in broad terms, the range of density for a steel billet falls between 7.75 and 8.05 grams per cubic centimeter (g/cm³). This density may exhibit slight fluctuations due to the steel's composition and quality. It is crucial to acknowledge that the presence of any impurities or contaminants in the material may additionally impact the density of a steel billet.

- Q: How are steel billets used in the manufacturing of industrial valves?

- Industrial valves rely heavily on steel billets as a vital element in their production. These valves are critical devices utilized to regulate the movement of fluids and gases in a wide range of industrial operations. Steel billets, which are partially processed metal products, play a crucial role in the creation of these valves. The manufacturing process for industrial valves typically involves multiple stages, including forging, machining, and assembly. Steel billets are primarily employed during the forging phase of valve production. Forging is the technique of shaping metal by applying localized compressive forces using dies or hammers. Steel billets are heated to a specific temperature and then subjected to intense pressure, causing them to take on the desired shape. The use of steel billets in the forging of valves presents several advantages. Firstly, steel is renowned for its exceptional strength and durability, making it an ideal material for valves operating under high-pressure conditions. Steel billets supply the necessary raw material to create sturdy and dependable valve components. Furthermore, steel billets can be easily molded and shaped during the forging process. This allows manufacturers to craft intricate valve designs with precision and accuracy. The versatility of steel billets facilitates the production of valves in various sizes, shapes, and configurations to meet specific industrial requirements. Moreover, steel billets can undergo heat treatment after forging to enhance their mechanical properties. Heat treatment methods such as quenching and tempering can greatly improve the hardness, strength, and wear resistance of valve components. This ensures that the valves can withstand demanding operating conditions and deliver optimal performance over an extended period. In conclusion, the utilization of steel billets is indispensable in the manufacturing of industrial valves. These billets provide the raw material necessary for forging robust valve components, offering strength, durability, and versatility. Leveraging steel billets enables the production of high-quality valves capable of efficiently controlling the flow of fluids and gases in industrial processes.

- Q: How do steel billets contribute to the overall weight reduction of a structure?

- Steel billets contribute to the overall weight reduction of a structure by being a lightweight and high-strength material. They allow for the design of thinner and more efficient structural elements, reducing the amount of steel required, and consequently the weight of the structure.

- Q: How are steel billets used in the production of reinforcement bars?

- Rebar production relies heavily on steel billets, which are integral components. These billets, resembling rectangular or square semi-finished steel products, act as the initial stage in the manufacturing process. To create rebar, the steel billets are first heated to a temperature surpassing their recrystallization point in a furnace. This procedure, known as hot rolling, involves passing the heated billets through a series of rollers. These rollers gradually decrease the billets' cross-sectional area while elongating the material. Consequently, the billets transform into long, slender bars possessing the desired mechanical properties and dimensions. Throughout the hot rolling process, the steel billets experience significant plastic deformation. This deformation leads to the realignment of grains within the material, resulting in a more uniform and compact structure. This refined microstructure enhances the strength and durability of the rebar, thereby making it ideal for construction projects necessitating high tensile strength, such as reinforced concrete structures. The size and shape of the steel billets employed in rebar production vary according to specific end-product requirements. It is crucial to note that the quality of the billets plays a vital role in determining the rebar's overall quality. Therefore, manufacturers must meticulously select and inspect the billets to ensure they meet the required specifications and standards. In conclusion, steel billets are indispensable in rebar production as they undergo transformation through the hot rolling process, resulting in the desired shape and dimensions. The resulting rebar exhibits enhanced strength and durability, rendering it suitable for reinforcing concrete structures and ensuring their structural integrity.

- Q: What are the different types of steel billet forging defects?

- There are several different types of steel billet forging defects that can occur during the forging process. These defects can have various causes and can impact the quality and integrity of the final forged product. Some of the common types of defects include: 1. Surface cracks: These are cracks that occur on the surface of the billet. They can be caused by excessive heating or cooling, improper forging techniques, or the presence of impurities in the steel. 2. Internal voids: These are cavities or voids that form within the billet. They can be caused by incomplete filling of the mold, improper venting, or the presence of gases trapped within the steel. 3. Inclusions: These are foreign materials or impurities that are present within the billet. They can include non-metallic particles, such as oxides or sulfides, or metallic impurities, such as slag. Inclusions can weaken the structure of the steel and reduce its overall quality. 4. Segregation: This refers to the non-uniform distribution of alloying elements within the billet. It can occur during the cooling process and can result in areas of the steel with different mechanical properties. This can lead to inconsistencies in the final product. 5. Dimensional inaccuracies: These defects refer to deviations from the desired shape or size of the billet. They can be caused by improper tooling or die design, inadequate heating or cooling processes, or improper handling during forging. 6. Grain structure abnormalities: The grain structure of the steel can be affected by various factors, such as improper heating or cooling rates. Abnormal grain structures can weaken the steel and reduce its mechanical properties. It is important to identify and address these defects during the production process to ensure the quality and reliability of the final forged product. Quality control measures, such as non-destructive testing and visual inspections, can help to detect and rectify these defects before the finished product is delivered to the customer.

- Q: How are steel billets used in the manufacturing of electrical appliances?

- Steel billets are an essential component in the manufacturing process of electrical appliances. These billets are semi-finished steel products that are typically rectangular in shape. They are used as a raw material for various electrical appliance components. One of the primary uses of steel billets in electrical appliance manufacturing is in the production of motor cores. Motor cores are crucial components in electric motors, which are utilized in various electrical appliances such as refrigerators, washing machines, and air conditioners. The steel billets are processed and shaped into laminated cores, which are then stacked together to form the motor core. These cores provide the structural support and magnetic properties necessary for the motor to generate rotational motion. Furthermore, steel billets are also used in the production of electrical wires and cables. These wires and cables are crucial for transmitting electricity within electrical appliances. The steel billets are processed and drawn into thin wires, which are then insulated and bundled to form the necessary electrical connections within the appliances. Additionally, steel billets find application in the manufacturing of electrical appliance housings and frames. These components provide the necessary structural support and protective covering for the internal electrical components. Steel billets are processed and molded into the desired shapes and sizes to create durable and rigid housings that can withstand the stress and environmental conditions of everyday usage. Overall, steel billets play a vital role in the manufacturing of electrical appliances by providing the raw material for motor cores, electrical wires, cables, and housing components. Their strength, durability, and magnetic properties make them an ideal choice for ensuring the quality and performance of electrical appliances.

- Q: How are steel billets inspected for surface cleanliness?

- Steel billets are inspected for surface cleanliness through visual inspection, where trained inspectors carefully examine the billets for any visible dirt, oxide scale, or other contaminants. Additionally, surface cleanliness can also be tested using methods like magnetic particle testing or ultrasonic testing to detect any hidden defects or impurities.

- Q: What are the different types of steel billet rolling defects?

- Some of the different types of steel billet rolling defects include surface cracks, scale formation, edge cracks, internal cracks, surface defects (such as pits, scars, and scratches), shape defects (such as bowing, wavy edges, and center buckling), and size defects (such as undersized or oversized billets).

- Q: What are the common shipping methods for steel billets?

- The common shipping methods for steel billets include sea transportation, rail transportation, and truck transportation.

Send your message to us

Carbon Steel Billets Square Billets hot sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16250 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords