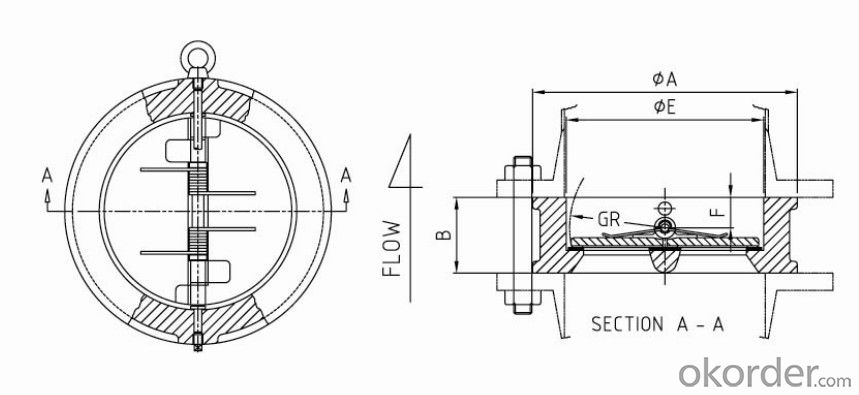

Swing Check Valve Wafer Type Double PN 16 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

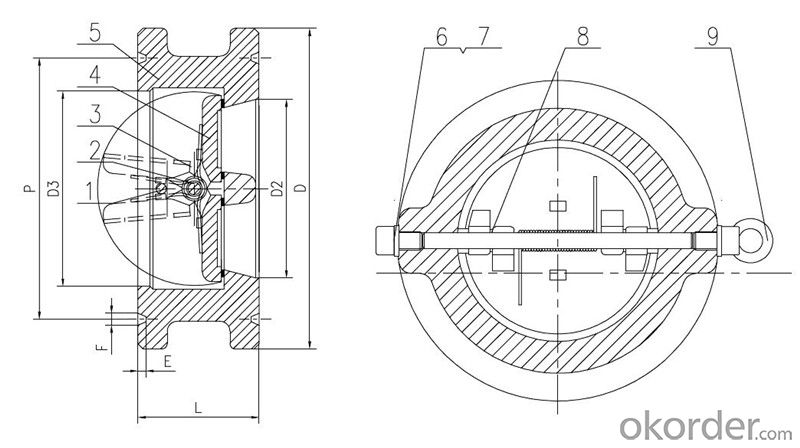

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: My 97 Tahoe has a leaking A/C pressure valve. I went to charge the system yesterday, and when I finished I took the hoses from the charging gauges off. The pressure side valve leaked. I pressed it down with a small screwdriver yet still couldn't get it to seat. I looks like it might have a damaged seal around the valve.Can I replace the valve? And if so, how. Or do I have to replace the entire hose assemble as they connect to the compressor?Thanks

- you need to have one door for the Heater or AC Coil - and it looks such as you have checked that one and this is working - yet another for sparkling Air or Recurculate and there ought to be yet another vent door it extremely is 'positional' placing a million, 2, 3, for floor face defrost - or extra in case you have a million/2 settings. --- on some autos / autos, this is extra suitable than merely one door IE: one door for each placing (and those are a discomfort). It looks like that door is the two no longer getting vacuume or this is 'caught' (each now and then issues from the sprint crumple in there and stick the door) - Actuate the door consisting of your hand, do no longer stress it too annoying you are able to ruin the acuator or the door - if it strikes and not utilising extremely some stress then initiate finding on the vacuume to the actuator - additionally make valuable the actuator will carry its place (circulate it to any spot, lick your finger (to make a reliable seal) and placed it on the hose connection to work out if this is going to hold.) --Oh, so confident, there is yet another door you are able to desire to be finding for --

- Q: Slow songs are a major factor of this this lagging sound. Note to Note. I Oil my Valves often and they still are slow. Am I just not using enough air? Help me Experts!

- Clean your valves properly. Use dish soap and a light plastic scrubbing pad and clean the inside the cylinder and the valve. If that doesn't work, try again using rubbing alcohol to clean the valve. Make sure that the valve guide and the little channel it fits in are clean. (use a toothpick to clean that place) You might also consider getting new springs. More air will not speed up the valves but it will help you maintain a constant sound.

- Q: This happens when the sprinklers are ON and goes on for a minute after the sprinklers go off. Should I replace the whole valve or do I need to check the diaphram or solenoid head? In addition to leaking, I have noticed a more potential problem - water hammer. As soon as the sprinkler goes off, I hear this loud banging noise from the pipes underground. Water pressure is fine ~ 50. My guess is air inside the pipes is causing this. Is this because of faulty valve which is leaking?Also, any difference between the valves that are sold in Lowe's and Home Depot to that of commercial valve? My lawn guy says commercial valves last a long time.

- The water hammer is due to the sudden closure of the control valve. They don't turn off slowly. The sudden shutoff of the valve causes the inertia of the water to slam against the end of the sprinkler pipe. You can device from a well stocked hardware store to place in you water line to reduce or eliminate the hammer. As for the leaking problem, I disassembled the control valve and found the diaphragm out of position. On mine, there is a very, very small key on the diaphragm that aligns it with the case. Also check for debris in the solenoid valve seat and anywhere else in the valve. I can't address commercial vs residential valves other than if the valves are brass, they are more durable.

- Q: I think the piece leaking is a valve;it is one solid piece of copper with two tubes, one which is a half inch that connectsinto the incoming hot water and then a small outgoing one that connects to the faucet and I don't know how to find a replacement part .. I think it is a Delta but I am not sure ... the house is 10 years old but where can I just find a valve instead of replacing the entire faucet if I don't know what the make or model is ?Any websites with pics of replacement valves for Roman Tubs??

- Remove the valve and take it to a plumbing supply store. Home Depot and the like may have what you're looking for; but you're more likely to find it at a plumber's supply. They are the only ones I've ever found who carry odd bits.

- Q: I have a '98 Dodge Caravan 3.0 and the valve cover gasket is bad. How do I replace it?

- take the bolts off pull off old cover and do the same with new cover!

- Q: I heard alot about blow off valves making your engine run rich, but I want to get a blow off valve or bypass valve when I get a wrx. (I know some people think they're gay) but i dont care how loud it is, just want that sound. so what's the difference? I've been looking at this one:

- They guy above has some of it. The reason it runs rich is because when the stock by pass valve releases the air back into the intake, it does this after the MAF sensor. Since it is getting a big surge of extra air that the MAF does not read, the ECU automatically increases fuel for a split second when the BPV releases. When you suddenly release all that air into the atmosphere, the computer does not know it and still ups the fuel. That seems like not a big deal but it runs really hot and can do things like foul up plugs and even melt the catalytic converter. There is also the issue with most aftermarket units causing stalling when you first step on the gas or even when sitting still. If you want a little noise, I would first look to getting rid of the intake silencer in the fender. It looks like a milk jug. If that's not enough, then look into an open ended intake. Just be careful with intakes as they also can cause issues depending on the brand and they rear of the car. At least an intake ca be tuned for though. The issues with a BOV can be reduced a little with tuning but can not be eliminated. Sow know that you know the risks and how it does absolutely zero to benefit the car, spend the money on something better.

- Q: had a water heater put in after that i have low hot water pressure it get hot but goes to a low stream.when i try to adjust gate valve it keeps turning

- A gate valve is used as a shut-off, not a regulator. It is supposed to be either all on or all off, and the handle only has a total movement of 90 degrees. When the handle is aligned with the pipe, it's on, and when the handle is perpendicular to the pipe it's off. If the handle is turning more than that, it's broke and needs to be fixed or replaced.

- Q: any flash files explaining valve operation maintenance will be very much helpful

- Pressure okorder /

- Q: In one of the two bathrooms - that we rarely used - I recently found that shower has now only hot water running. The valve is Moen brand with a single knob. On turning this, I get no cold water, but just hot water. I removed the knob, and decided to maybe replace the cartidge, but could not make any headway, after removing the acrylic knob. First, do I need to remove the cartridge?If yes, how? Is it possible to remove it without removing the back-plate glued to the Tile walls? Will appreciate detailed instructions to remove or fix the valve?thanks

- the valve should have a c shaped clip holding it in. do that with the water shut off. if you have cold water to the tub spout, maybe the valve body is clogged with sediment, or a CW valve has collapsed.you have to remove the back plate to access the valve body.

- Q: I've been diagnosed with mitral valve prolapse, my doctor just told me that i need to setup an appointment with the hospital to look at treatments for heart mitral valve prolapse-to possibly have a heart valve replaced. I am wondering if i should setup an appointment with mayo clinice in minnesota to get another opinion on that? I'm wondering if surgery is an only option available to me, i have been taking beta blockers that have been no help for the past 3-4 months. Thanks.

- Beta blockers. These drugs help prevent irregular heartbeats. They work by blocking the effects of the hormone epinephrine, also known as adrenaline. As a result, the heart beats more slowly and with less force, thereby reducing blood pressure. Beta blockers also help blood vessels relax and open up to improve blood flow. Valve replacement. Valve replacement is done when valve repair isn't possible. In valve replacement surgery, the damaged mitral valve is replaced by an artificial (prosthetic) valve. The two types of artificial valves are mechanical and tissue. Mechanical valves, which are made of metal, may last a long time. However, if you have a mechanical valve, you must use an anticoagulant medication, such as warfarin (Coumadin), for the rest of your life to prevent blood clots from forming on the valve. If a blood clot forms on the valve and breaks free, it could travel to your brain and cause a stroke. Tissue valves are made from biologic tissue such as a pig's heart valve. These kinds of valves are called bioprostheses. They may wear out over time and need replacement. However, an advantage of the tissue valve is that you don't have to use long-term anticoagulant medication. Please see the web pages for more details on Mitral valve Prolase and Heart valve surgery.

Send your message to us

Swing Check Valve Wafer Type Double PN 16 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords