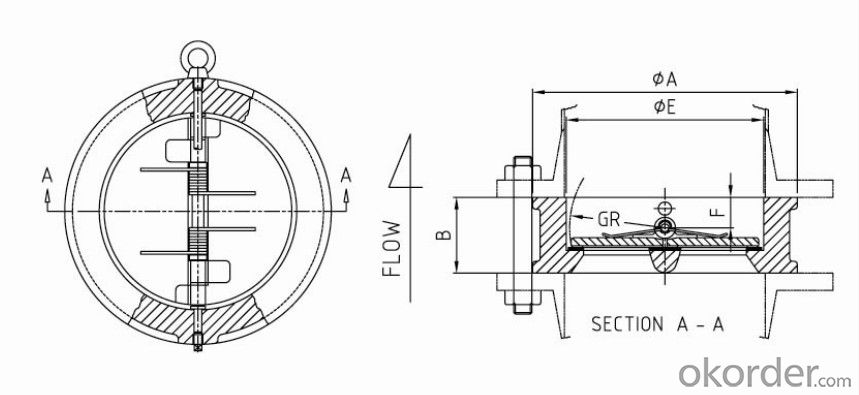

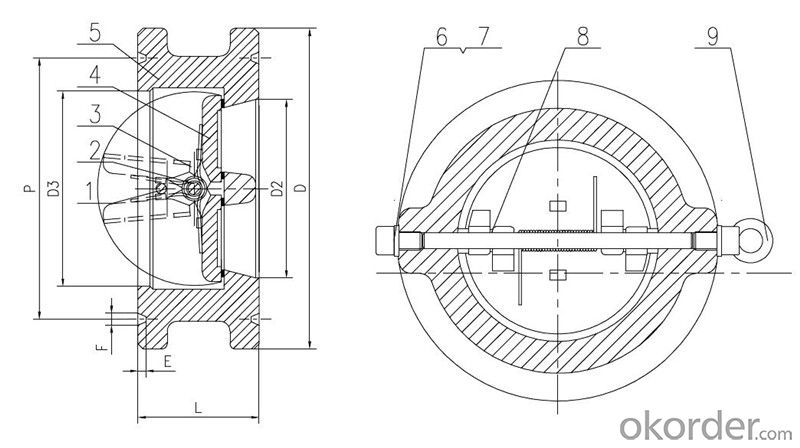

Swing Check Valve Wafer Type Double Disc Body Material CF3M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I have a 2000 Ford Explorer sport(2wd). I live in the Fort worth,Tx area. What would be a resonable price to have this valve changed out with a new one(valve labor)?

- Valve is about $100 at dealer, $40 at Autozone, give or take, and it should take about 30 minutes, so I would guess about $150 max. I have same problem with 2002, trouble is it's on the transmission, and not that easy for a DIY. As to changing it, mine has caused the check engine light to go on, but has in no way effected the car, so I haven't bothered to change it yet.

- Q: Hi My sons car has alloy wheels, and metal valve stems, there is a tiny leak between the valve stam and the alloy on one wheel, we are struggling to get anyone to repair at a reasonable cost. Would tyre weld make a permanent repair?. Some tyre specialists won't touch the wheel, one other wants to drill out the stem put in another, which sounds a bit drastic. Any other ideas?, is it feasible to get the metal valve stem replaced by a rubber version?. Apparently the metal ones get curbed and then start to leak.

- On that year car the tire is tubeless and the valve stem should not be moving as it would if you had a tube type tire. If the valve stem is pushing in it means you drove on the tire while flat and probably ruined the tire as well as the valve stem. The tire must come off the rim to be inspected before blowing it back up and used. If you don't inspect the tire it will probably blow out at highway speeds and kill someone!

- Q: I'm in the process of replacing my dishwasher but I have a problem. I followed the water line from the dishwasher to under my sink and found a red valve that was completely straight, so I turned it to the right as tight as it would go and tried removing the hex nut connecting the line to the dishwasher. Maybe i'm wrong, but there is a lot of water coming out of the line and I don't think it's supposed to. I easily filled up a bowl you would use to mix cakes and it was still going! So, I turned the valve back to straight across thinking maybe someone else turned it off (my dad), and tried it again but the same thing? What am I doing wrong and what should I do to solve this?

- If you have cut off valves below water lines going to the dish washer,turn them off. There should be a hot and cold water line. Red is used to designate the hot water line and blue for the cold water line. If all else fails,turn the water off at the water meter,this turns off the water to the whole house.

- Q: The valve on my radiator has numbers on it to determine the amount of air/steam leaving the heating system. what number should i put it on and how would i determine it

- I would think the easiest way would be to put a thermometer on the radiator (with the bulb in the air flow), turn the heat on to one setting and record the temperatures each half hour for about 4 hours. Then, turn the adjustment to a higher (or lower) number and repeat that. That way, you'd know which way to turn to set it. Of course, the level at which you'd be comfortable would be found by trying different settings. Assuming the adustment is a valve, valves in the USA will open by turning counter-clockwise. Closing is, of course, clockwise. Hope that helps. EDIT: I received your email - I don't mind at all! OK, so you have only one valve for all the radiators. Without knowing anything else, I'd say you just removed the part called the bonnet (the upper half of a valve). It shouldn't matter which number it's set on if it's reinstalled correctly. When a valve is removed, the best way to put back is to open it slightly (turn counterclockwise to a low number), then reinstall the bonnet. Once it's back in, it should work like normal. If that doesn't work, perhaps you can get a plumber or a local handyman to check it. As to the upper ones being airlocked, it really sounds like there is a blockage in the supply line. I am assuming this is steam-heat radiator that is supplied by a boiler-type heating unit?

- Q: I have the correct tools and have done this before. All I want to do is change all three valves that operate the water (hot,diverter,cold). The shower is leaking. I want to change all three valves to stop the leak. I will call a plumber if I can't change the valves or stop the leak. Please tell me what tools I need and I'll begin from there. I have three handles/valves in the shower(cold,diverter,hot).The cold is here # and the diverter is in the center which is here # and the hot is here #. They all line up like this c# diverter# h#. These are how the valves are set up # # #.

- Drill out the set screw. It's most likely brass and will drill out easily. Cut an access in the wall behind your shower wall and just replace the whole thing. This will probably be the easiest fix. It may sound like a lot, but in the end you will most likely save time.

- Q: I was wondering if anyone knew how important tire valve stem caps were in maintaining inflation pressure in auto tires? I noticed one of my tires losing air slowly (from 30 psi to 21 psi in about a week) and this tire (unlike the other three) also had a missing tire valve stem cap. I've just replaced it, and was wondering if a missing valve stem cap caused faster loss of tire pressure.

- The only way it will leak is if the valve stem core is loose. There is a tool sold tighten it. Take some dishwashing liquid and mix water with it. 30% dishwashing liquid and 70% water. Poor a little on top of the valve stem. If it is leaking it will bubble.

- Q: does a 1975 chevy pickup 2wd has a proportioning valve? If so how does it work and the signs it is bad? my truck has disc/drums brakes?

- Yes they do go bad! It sounds like that is your problem. You can try bleeding the proportioning valve with a brake bleeding gun, making sure to open every valve then re-bleed the brake system this will eliminate the possibility of a air bubble in the proportioning valve. I have changed probably ten or twelve of these things in my ventures.

- Q: right after it come through the foundation. Should it be a gate valve?

- Older homes will have a gate valve, newer homes would use a ball valve. Any type of valve would be proper as long as it seals.

- Q: The water inlet valve on my Kenmore washer leaks. Is there an easy way to replace it? Last time it broke they charged me over $100 to fix it.

- YES okorder when you get there you will need your numerical model number that you will find by lifting the lid of the washer looking down and toward the back of the machine just under the lid where its hinged. Once you type in the model number do a word search by typing in valve. It will give you a numerical part number that you can call your local service company with and get a price. Or you can usually call any service dept local with your model and they can look it up for you and sell you the part. Good luck...

- Q: how long do people usually live after mitral valve repair?

- From what i've got study having it repaired rather than replaced has a much greater helpful restoration consequence. The survival fee is in the mid ninety's % clever so curiously like an rather secure surgical operation. Hoping she has a rapid restoration.

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material CF3M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords