Swing Check Valve Wafer Type Double PN 1 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

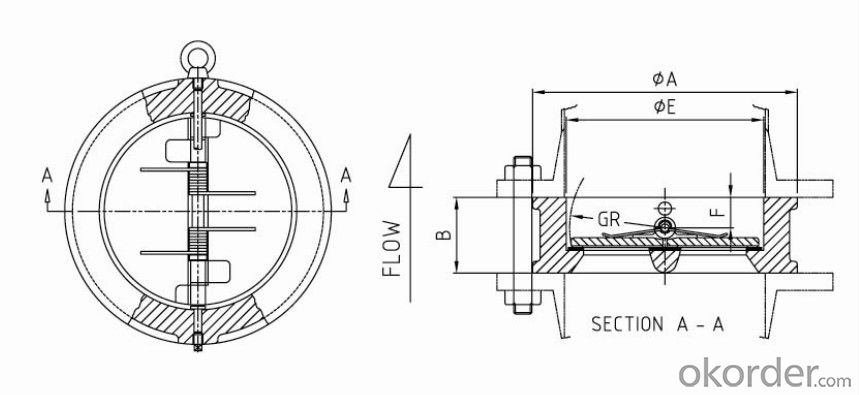

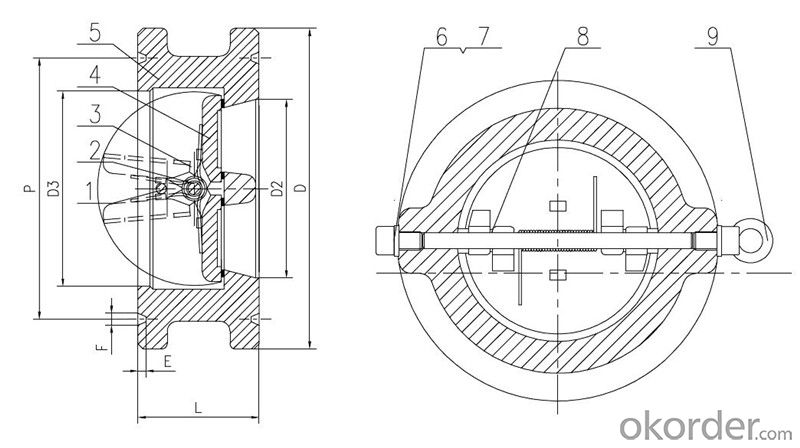

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: how could you make a valve or a system so that when it is pressurized, if enough pressure is reached in the system the valve will open completely and remain opened until it is close manually?I'm thinking about this in the context of an air powered dart gun, so that the firing mechanism is like a piston, and when a certain air pressure is reached, the valve that connects to the barrel will open and fire the dart

- One thing you can do is get a pressure switch and a solenoid valve so that when whatever you are pressurizing comes to a certain level the switch will close it's normally open contacts and energize the solenoid which will open the valve. However as soon as the pressure level goes below the trigger level the valve will automatically close.

- Q: Which is worse ? And what causes it? I was told I had mitro valve prolapse but I m symptoms had worsen and so I saw a cardiologist again today and they said I have mitro valve regeritation.

- MItral vale prolapse is the problem that is causing the regurgitation. Regurgitation is backward flow of blood. Prolapse is a situation where an anatomical part has slipped out of its normal position. When a heart valve is prolapsed it doesn't close completely, and blood leaks backwards when the heart beats.

- Q: I got a 2012 peterbilt 386 ...it just came back from the shop a few day ago to get injectors 4 and 5 looked at and repaired ....I'm getting a fault code for injector spill valve and a engine light ....I tried resetting the computer to get rid of the code but that's not it ... uld timeing of this cause the problem ...but other than that it runs like a champ so what could I do to fix this is it time cause I did probably get re timed when they repaired it

- The fault for the spill valve is not something you can correct with timing. When they repaired or replace injectors they need to be programed into the computer so they match the other injectors. The spill valve is in the injector and is there to return unneeded fuel back to tank. If this valve does not work you could be over fueling or run the risk of fuel cooking in the injector making a mess of the spray pattern. It should be telling you which injector is throwing the code and if it is one of the two that were worked on take it back.

- Q: This happens when the sprinklers are ON and goes on for a minute after the sprinklers go off. Should I replace the whole valve or do I need to check the diaphram or solenoid head? In addition to leaking, I have noticed a more potential problem - water hammer. As soon as the sprinkler goes off, I hear this loud banging noise from the pipes underground. Water pressure is fine ~ 50. My guess is air inside the pipes is causing this. Is this because of faulty valve which is leaking?Also, any difference between the valves that are sold in Lowe's and Home Depot to that of commercial valve? My lawn guy says commercial valves last a long time.

- I have been given the equivalent line from our water application whilst the stress valve broke and blew up our water softener it rather is the 1st element on the line from their tension regulator. luckily, it has a life-time insurance yet their plumber instructed me that it extremely was once the accountability city on the grounds that of the stress regulator which they admitted to being at fault whilst they replaced it.

- Q: the blow off valve has a hose that goes to the intake. Do you need that hose.

- if you want it to operate properly the yes you will need it. The valves are also adustable but you need a tech manual to and special tool to do it propperly dont just guess at its setting rather know it. I assume the picture i looked at was your engine. Unless you like taking chaces i would recomend you put your timing belt cover back in place. If anything should get in there between your t-belt and gears or pullys the belt could be damaged and if it does get damaged you could damage the valves in the event of t-belt failure. I know people like to see the belt and gears moving and if that is what you are wanting i would suggest installing one of the clear t-belt covers that are available. unfortunatly i do not know who makes them. if you cant find out go to a car show and talk to gear heads that have them on there cars.

- Q: I think they need to be taught how to count. Honesty... Half-Life, Half-Life 2, Half-Life 2: Episode One, Half-Life 2: Episode Two... Where the hell is 3 already?

- VALVe is busy with Dota 2 and CS:GO. I hope they count to 3 after they finish those games.

- Q: I took my 2nd valve out to wash it (i couldn't find my oil, but it worked fine) and I've tried making the number face the mouthpiece, yet it still is messed up and won't let me play a lot of notes.

- see if there is a slight protrusion on the valve. probably on a piece of plastic near or above the spring of the valve? that should fit in a notch in the trumpet valve tube. Just insert your valve partly in until the protrusion is resting on a ledge-like part. Then turn your valve around the tube gently until you hear a click when the notch goes in. You are right, the number on the valve usually faces the side where the mouthpiece is. Make sure your other valves are also placed in there correctly. If all else fails, ask the person who's teaching or taught you to play trumpet. or go to a trumpet store. Enjoy practicing!

- Q: This is my first tranny install and there is one thing that i really think i f'd up on. I'v been installing a junk yard 700r4 and transfer case into this beater 1990 k1500. Everything is in i'm just waiting on a new throttle valve cable (detent cable) to put it. But me, being my first tranny install, thought that the piece inside of the transmission that the detent cable attatches too.....came out. which i later found out that it doesn't, and that the TV cable just connects to it. I yanked on it pretty good with some pliers, and it never came out, and it still moves up and down. My question is could i have done some serious damage to that peice and the throttle valve itself???? let me know what u think.... thanks!

- 700r4 Throttle Valve

- Q: adjusting the overhead valves on briggs and stranton 14.5 engine

- Roll the engine over until the valve is completely closed. You can do this by watching the valve close, then turn the engine over until it just strats to raise. Now turn it back half way. Now losen the rocker arm and place a .003mm to .005mm filler gage between the push rod and the rocker. Tighten the rocker arm nut down so that the filler gage pulls out with a light drag. Do this with the other rocker and you are good to go.

- Q: I need to find a solenoid valve with the following specifications:2-way, 1 inch nozzles (both male)needs to be able to handle the pressure from a CO2 tank (~1000 psi)needs to work with 12vdc less than 10 ampsits either a solenoid, or some other type of valve which will release the CO2 when we tell it to electronically

- The leading maker of solenoid valves is ASCO. Their website is shown below. If a valve that fits your application exists they probably make one. If you can't find a suitable solenoid then you need to consider a pneumatic valve operated by a solenoid valve. That is a common solution for a problem like yours. As to the male connections. If they are not available then you can just use a pair of threaded fittings (pipe nipples) to change the configuration.

Send your message to us

Swing Check Valve Wafer Type Double PN 1 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords