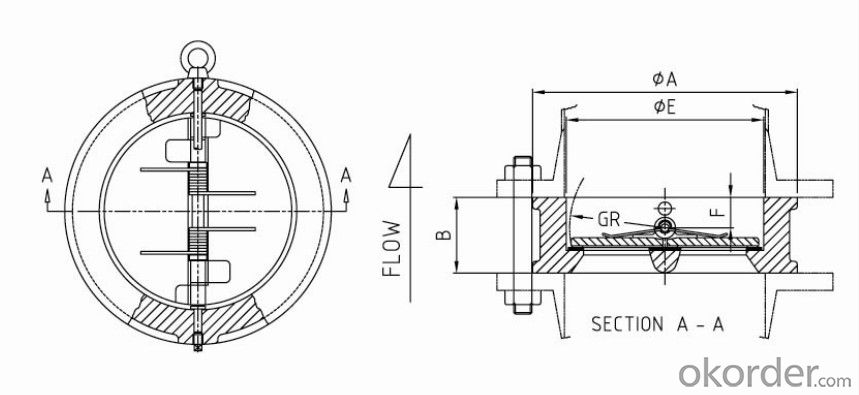

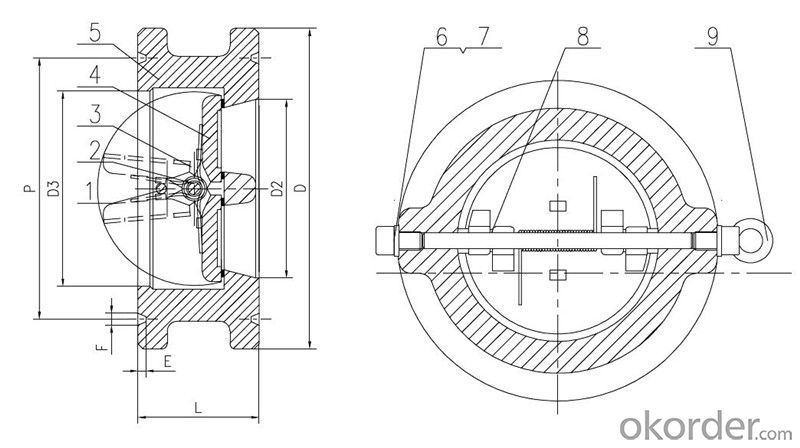

Swing Check Valve Wafer Type Double Disc DN 300 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Where is the Auxiliary Air Valve on my 98 Civic?I have a 98 Honda Civic ex and need to change the Auxiliary Air Valve

- l was told by a mechanic that I had a bad auxiliary valve and I would cost $1200.00 I can t find information on such a thing. Douglas

- Q: the valve stem?

- Just buy a new one for goodness sake!!!

- Q: people tell me i need to install new valves and valve guides

- You might not need new valves or valve guides. Mitsubishis, along with many other vehicles, use hydraulic lifters which give off a ticking sound. They're located between the rocker arm, or in the rocker arm, and the head of the valve. It's very common and will not harm the engine. However, if the sound you're hearing is more of a rattling, like putting some nuts and bolts in a glass jar, you may need to pull the valve cover off and inspect for yourself to make sure that the rocker arms do not have any play to them while they are pushing on the valves. If there is any play in the rocker side to side, you may need to replace those rockers. However, if there is any play up and down you may just need to replace the lifter. To better check if you need new valves or valve guides run through this checklist: Are you burning oil? Have you done a compression test (both wet and dry)? And if so, were the compression numbers within spec? Have you felt a loss in power/idle quality/gas mileage? Is your oil level correct/using the correct oil/non-FRAM oil filter? At your next oil change, instead of using the recommended 5W-30 engine oil, try switching to something a little heavier, such as 10W-30, to cancel out the effect of possible lifter tick. Do not use a FRAM oil filter if you have in the past since they're filters tend to have additives that are unnecessary and may cause the engine harm.

- Q: What's the safety valve (relief valve) type?

- The four common types of pressure relief are the spring loaded valve, the rupture disc, the balance bellows spring loaded valve and the pilot operated relief valve.

- Q: Was wondering if there is something I could purchase to put into a car so that it will become a 24 valve????

- You'll just have to buy a vehicle that has a 24 valve engine man.

- Q: okay so i recently brought a trumpet and the valve keys were getting stuck. i used the valve oil and it worked. but then when i put the valve key back in and tried blowing through no sound came out. i think it's because i didnt put it back in right. now my question is how do i put it in right? i tried everything but it's still not making a sound. thanks,

- The first thing you should check is the order of the valves. take them all out and look on the sides of them for a number. One should have a 1 on it, another will have a 3 and the other one will probably be unmarked but that's obviously the one in the middle. On the outside of your trumpet there will be a 1 and a 3. The valve with the 1 on it goes in the slot that has a 1 on the outside, etc. Make sure you put these in right. if it's still not playing after you put the valves in and they're secured, twist the tops of the valves where the pearls are clockwise until they don't turn anymore. This should fix your problem.

- Q: i have a '96 buick skylark and my check engine light is on...i got it checked and the test said it was my EGR valve. does anyone know how to explain in lamens terms how to replace my EGR valve??????

- The EGR recirculates exhaust gas into the combustion chamber. It is usually two bolts, and sits ontop of the intake manifold. Usually pretty easy to change youself. Unhook the single vacuume line, take out the two bolts, and reverse the installation! Zach

- Q: I bought my first car recently. but it has a high idle and smoking problem, i already replaced the spark plugs. I've been reading about the exhaust gas re-circulation valve. but i cant find it. where exactly is the EGR valve located in a 1999 KIA Pride?

- the EGR wont reason a hissing noise, if the EGR replaced into undesirable, there could be a soft stumble off the line, or tough idle. a hissin noise sounds like a vacuum leak someplace. open the hood while the vehicle is working and notice in case you may hear the place the hissing is coming from. it ought to be coming from a line someplace.

- Q: To control a double solenoid valve, what do you recommend to use in my PLC program .... Do you recommend to use the SetReset coils or to use the normal coils?

- It depends on the valve construction. If it's a 2-way valve you may need to hold it open by keeping the output energized until you want to shut it off. In this case I would use Set and Reset instructions. If it's a 3-way valve with a block center that hold pressure on that side of the cylinder, a simple OTE instruction will work fine.

- Q: My furnace cut out about a year ago. The hvac guy i used told me the gas valve was no good and that the flu was partially blocked. I cleaned out the flu, he replaced the gas valve ($700+) and it worked great for a year. Today the furnace does not fire up. Pilot is working. I cleaned out the flu (there was definitely quite a bit of debris, so that was probably the cause for the shut off) .... The flu is now clear, but when i turn the system back on the thermostat calls for heat, but there is no gas flow to the burner... could the valve have failed that quick, or should i be looking at something else like the CO sensor or something... just looking for some direction before shelling out another 700 bucks... Thanks in advance for any ideas or assistance....

- There are a few possibilities. The valve runs on a low voltage line. The low voltage is provided by a transformer. It it possible the transformer is bad. Be sure the power switch to the furnace is on. (should be on the side of the furnace. Easy way to check is (on the thermostat) turn the fan switch from auto to run. The blower fan should come on. Check that the gas valve is in the ON position.(if you have had to light the pilot it may still be in pilot position.) Another possibility is a clogged gas line. If you have an older home rust can accumulate inside the iron gas lines. Where the gas line attaches to the furnace there should be a drip leg. This is a short length of pipe that points down with a cap on it from the TEE that goes into the furnace. This short piece of pipe is to catch any moisture or rust that comes thru the line. First TURN OFF the gas at the shut off in the pipe it's self. This is a quarter turn valve. When the handle is in line with the pipe the gas is on. When it is opposite the pipe (pointing out to the side) the gas is off. After turning the gas off, remove the cap from the bottom of the drip leg to remove any accumulation.USE PIPE DOPE not teflon tape when putting the cap back on.Turn the gas valve back on and check for leaks.

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 300 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords