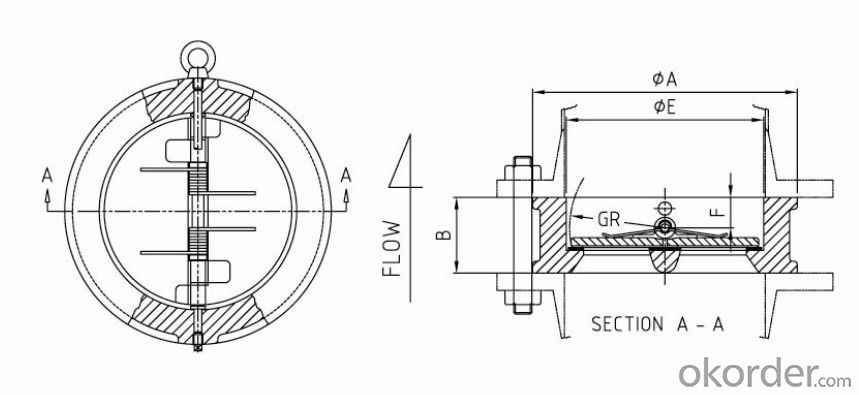

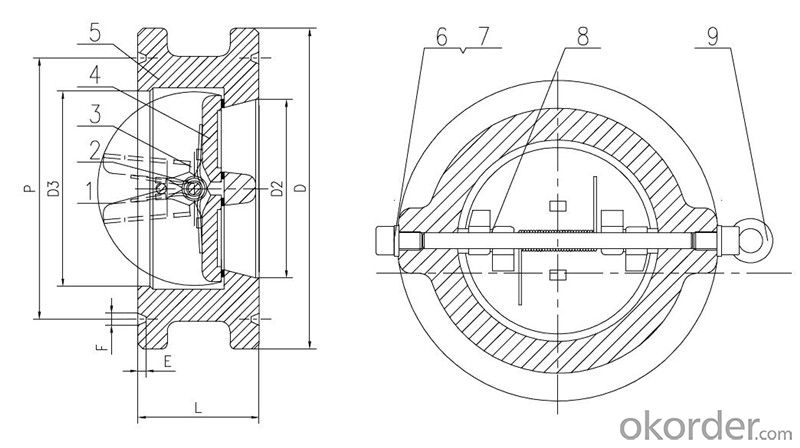

Swing Check Valve Wafer Type Double Disc DN 200 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I dont want to buy an expensive snorkel, because I only want the valve. Its for a project for a club where I go to college.

- try amazon and OKorder

- Q: When using seafoam through the PCV valve. Which side contains the vacuum? From the crank case of intake manifold? The brake booster line is very difficult to access and on their site it says I can apply seafoam through the pcv valve.

- On most engines the PCV Valve is located on the valve cover. You would remove the PCV valve from the valve cover but leave it connected to the vacuum hose. Otherwise you would have a severe vacuum leak and the engine would race wildly. With the PCV valve still in place the engine would idle somewhat normally. Pour the Sea Foam directly into the PCV valve. The Sea Foam would be sucked into the PCV valve and into the intake manifold. Be careful not to over do it on the first application. If this has not been done for a few years enough gunk can be washed out of the intake manifold that it can foul the catalytic converter. I would apply the Sea Foam. Have a friend shut off the engine while the Sea Foam is added. Allow the Sea Foam to soak for several minutes and do its job. Reconnect the PCV valve. Start the engine and drive the vehicle for several miles. This will allow the catalytic converter to burn off the gunk that and Sea Foam that has passed through the engine. Repeat as necessary.

- Q: 1999 Mercury Cougar in awesome shape no engine problems, and has just under 86000 miles. I bought it recently and the check engine light came on out of nowhere and I realized It was an EGR issue the code was p0401 insufficient flow. I had a mechanic replace the solenoid valve as well as clean all of the carbon gunk off the valve and the light was off, then suddenly POPPED back on, making me really nervous and kind of upset. So today I had a few errands to run and I said I wasn't going to go get it read again until tomorrow, and it just Went off. So Is the car just very sensitive to things and is that why it goes on and off? Or is something wrong? I'm a student who really wants to keep this car nice like I bought it.

- Ford vehicles commonly have this problem. Their is a sensor that determines the flow of the EGR. This sensor is called Differential Pressure Feedback Sensor or (DPFE). originally the cougar's came with a plastic DPFE they became brittle from the high engine bay temperatures. There was a newer revised part that is now metal to withstand high heat. 86k miles is roughly when you see them go bad. 9 times out of 10 on a ford the sensor is bad not the ExhaustGasRecirculation Valve. I say replace the sensor, or pay to have it diagnosed properly. And a loose gas cap will give you a gross evap leak code not a egr code.

- Q: Ok so i am 16 years old, and i have Aortic stenosis, bicuspid aortic valve, aortic regurgitation and an Enlarged aorta. I am soon going to be getting an aortic valve replacement. I am just wondering what happens before and after the surgery and how long i will be in the hospital, how long in the ICU, what kind of tubes/machines will i need? any information will help. thanks :)

- Mechanical valve will last for ever. But the red blood cells will be damaged and clot will be formed in the implanted mechanical valve. In order to prevent the formation of blood clot, the patient has to take warfarin (a blood thinner) for the rest of his/her life. If pig valve is used, there is no necessity to take the medicine (warfarin) for the rest of his/her life. But the tissue valve will function only for 15 years. Since you are too young, you have to opt for mechanical valve and to take the medicine for the rest of your life. Valve replacement is indicated for virtually all who can tolerate surgery. In younger patients, the patient's own pulmonic valve can be used, providing good durability; a bioprosthesis is then used to replace the pulmonic valve (Ross procedure). Most often, the aortic valve is replaced with a mechanical or bioprosthetic valve. You will stay in an intensive care unit for the first 2 or 3 days following the operation. Your heart functions will be monitored constantly. The average hospital stay is 1 - 2 weeks. Complete recovery will take a few weeks to several months, depending on your health before surgery.

- Q: My grandfather is going in for a valve replacement.. and I'm really worried about him.. I just want some information.. any good websites if you have them.. I looked on google.. But if you have any good ones that would be great..No horrible comments please..

- I don't know much about it, but as far as I know, it's become a relatively routine procedure. Personally, the surgeon I'd want to do it on me is the guy who does 20 or more of them a week, instead of the guy who does two a month. The more frequently they do the procedure, the more adept they are at it, do you know what I'm saying? Good luck! I'm sure your grandfather'll do fine!

- Q: My boyfriend just went to his heart doctor and his tricuspid valve is leaking because of his pacemaker wire. They are saying that its moderate to severe. We are trying to decide on what moderate to severe really means. They said the same thing when he was at the doctors in June.

- if actuality be told whilst your valves close, there is a few returned pass instead of all your blood being pushed forward.. gentle regurgitation often does not reason challenge, yet you may get regarded at each year to visual show unit if it gets worse or no longer. you does no longer ought to get valve replace surgical technique till it extremely is reasonable to severe. if so, you will have the flexibility to observe with the aid of fact it could reason shortness of breath and because your blood pass isn't optimized.

- Q: My check engine light is on in my 1999 Toyota Camry XLE...I went to autozone and they told me it was my egr valve BUT they did not tell me if it need to be cleaned or replaced. How can I tell if it needs to be cleaned or replaced

- Flag is right. You should of got the code from AutoZone and posted it here. A trouble code can have several meanings and the salesperson just gave you his best interpretation with his limited knowledge. You either had a P0420, P1410, P1411, P1661 or P1662 code. More than likely it's EGR Valve Position sensor or EGR Vacuum Solenoid depending on the code. It also can be the wires or connectors that plug into them or one of the vacuum hoses to them. About a $40-$70 fix if you do it yourself. You can pull the EGR valve off to inspect it but you need to replace the $1 gasket under it when you are done. On old poorly maintained engines they can clog up with carbon deposits or the vacuum diaphragm can rupture. You can apply vacuum to the valve manually and see if it opens while you have it off. If you have good lungs you can do it with a piece of hose. :) If it works then it's not getting vacuum and most likely it's the EGR Vacuum Solenoid that opens and supplies vacuum to it. The EGR Valve Position Sensor tells the Vacuum Solenoid to open via the ECM. See if you can't get the code and post it.

- Q: my check engine light tells me that i need an egr valve, if i install one will that cut the light off????

- Possibly. If you don't go out then you need to have someone hook up a code reader and clear the SES light.

- Q: I'm going to replace a valve guide and wondering how I should do it.Should I drill into the existing valve guide to the point it's small enough to pinch with some pliers and pull it out?When I put the new one in, should I use a wooden dowel and an air nailer to pound the guide into place?The more info. the better. It's my first time doing this.Thanks!

- Ohhhh man. NO DRILLS. I assume you are referring to an Aluminum Cylinder head. To do it correctly you need a drift punch that has a pilot size of the valve stem, and an outside diameter that is just a few thousands smaller than the guide. Disassemble the head completely, put in Moms oven at the highest setting it will go to ( 5-6 hundred degrees ) Pound old guide out from the combustion camber side. ( have every thing ready to go this FFer will be hot ). Coat new guide with something like STP, put in freezer, carefully align it, then slam it home from the valve train side, don't pussy around, get it in before it attracts the heat of the head, if you stop or it stops you will have to repeat the entire process. If you gall the Aluminum ( say O-**** ) Since you have to hit this thing fairly hard you will need to refinish the inside of the guide with the appropriate reamer. Then refinsh Valve seat ( they never, NEVER line up perfectly )

- Q: i have a 1987 nissan 300zx and i can get the car to start unless its 40 degrees and when it does it idles hard. is this idle control valve or a fast idle valve??

- Could be.. Also could be dirty. Easy fix, remove the valve and spray carb cleaner in the hole.. Using a small brush, clean the bore that the valve rides up and down in. Also, inspect the valve while it is off the manifold. Harder fix: After cleaning the bore, replace valve with brand new one. Your car will have to relearn the idle after starting with the new valve or after you put the old one back in.. Start car, but do not put it in drive or give it any throttle until the computer has finished making adjustments. - Dave. (Long Island, NY)

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 200 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords