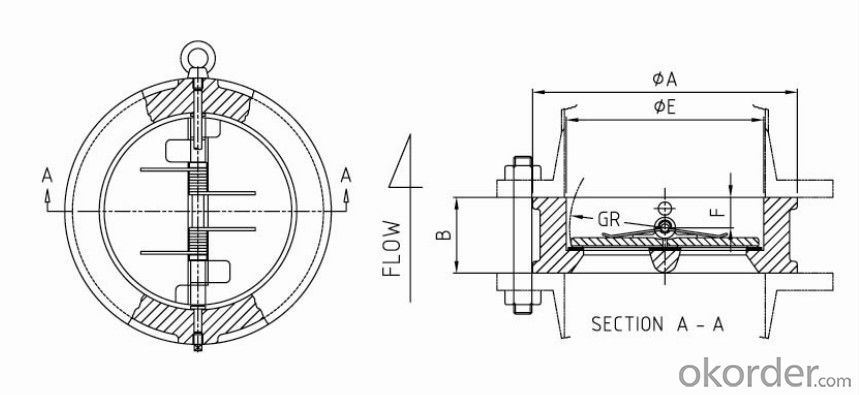

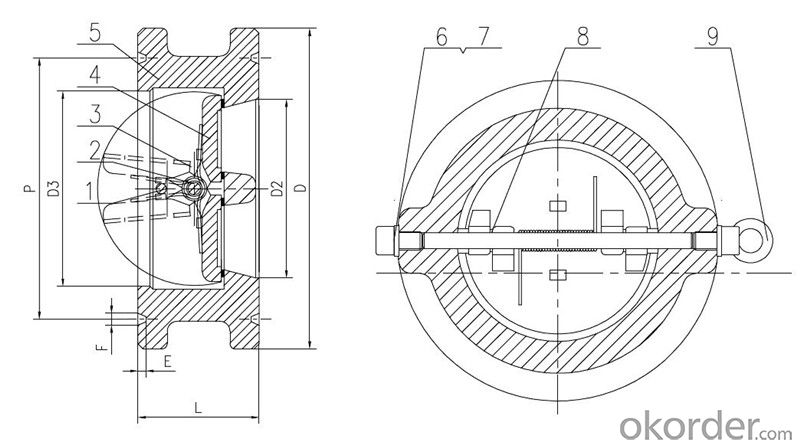

Swing Check Valve Wafer Type Double Disc DN 350 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: So I tried to go skydiving last weekend and they told me know because I have mitral valve prolapse. I've had it for years and it's never really been a problem for me, I just have chest pains sometimes and feel palpitations. What would be the danger of not telling the skydiving place about my problem the next time I go in? I know I should tell them, but I want to skydive. What could happen to me if I jump? No lectures about what's right and wrong here please. I just want to know what's the worse that could happen?

- There are many people with mitral valve prolapse that never have symptoms related to it and never have any problems as a result. Mitral valve prolapse can lead to the backflow of blood through the mitral valve known as mitral regurgitation. This can potentially lead to abnormal heart rhythms, such as atrial fibrillation. The concern with skydiving is that it would lead to a surge of adrenaline resulting in increased heart rate, strength of heart contractions and overall workload of the heart. If you have MVP without regurgitation, then your risk would be similar to the general population. If you have regurgitation it depends on the severity the regurgitation. If you have mild regurgitation, then it also should not be a problem. If you have severe regurgitation, then you could run into problems from the increased workload of the heart. In this case, I would suggest you discuss it with your Cardiologist. It is unlikely that you have atrial fibrillation. If you by chance do, then it depends on how well your heart rate is controlled. If there is any doubt, then ask your Cardiologist. Good luck.

- Q: I replaced the valve cover seal and I wanted to know the torque specs for the valve cover bolts and the sequence it should go

- This Site Might Help You. RE: What is the torque specs for a valve cover? I replaced the valve cover seal and I wanted to know the torque specs for the valve cover bolts and the sequence it should go

- Q: Hi all, I found oil leakage in my distributor and am about to change the o rings. however, i feel that a blocked PCV valve is causing the pressure to push oil into the distributor. I have been searching for the PCV valve. Can someone please tell me where it is?

- The PCV valve is located beneath the intake manifold on the right (passenger) side. It threads into the breather seperator and points toward the center of the car. To remove it, you'll have to remove the Idle Air Control valve located on the end of the manifold log. Be aware that you'll have to do at least part of this task underneath the car, and that the IAC valve has antifreeze circulating through it Get a mechanic to do it if you can afford it

- Q: so, im a day away from getting a 2002 748 and im super excited, iv always wanted a ducati, and i cant wait to have one of my own. i understand that ducks have a reputation of breaking and im prepared for it. I also understand the valves need to be adjusted every 50-100 feet :P all kidding aside i know every 6k miles they need to be adjusted. i dont know however how much it costs to have the valves adjusted. im sure it varys from shop to shop but a ball park quote would be really helpful just so its not a kick in the gut when i take it in for the first time. thanks

- Well first, you need to get them inspected, and they'll only adjust the valves if it's needed, even at 6k mile intervals, if your valves are still in spec or very close without lobe drag, they probably won't be changed, so check your bill and ask your tech directly if they were changed, some less reputable dealers may try to pull a fast one on you. If you actually needed ALL 16 shims changed, you're easily talking $1000 in labor, esp. on the 748/916 style heads, which have access ports on the heads instead of being able to remove the whole top of the heads like the newer DESMOQUATTRO heads, and are a PITA to work on because of it. The bad thing is that until recently (and they still need improvement) Ducati's quality control is lower than other manufacturers, meaning very inconsistent performance reliability, just from variances in manufacturing. If you get a GOOD tech to do the bike right in the first place though, not just valves but all-important TPS resetting, cam timing/belt tension, and balanced CO's in your exhaust, you will have a lot less headaches with your Duc.

- Q: my EGR valve has gone on my Vauxhall Vectra 2.0 DI LS, 1998, 5 DOOR HATCHBACK, so i am getting a new one next week, what i want to know is, is it an easy job to replace them if so how do i do it? or is it better just to let a garage do the job?

- Easy. Just google it and it will tell you how. It will take a minute to change.

- Q: so here are the details. i've been using my trumpet for about 6-8 years now and 1 if not 2 valves get stuck on my trumpet. the problem is not the oil as i have over oiled them too and no go. its that when i try to put my valves back in their place and twist them they don't stay in place,move ,and making either my valves stuck or making my trumpet not do a sound. what should i do? repair shop or buy a new one? i hear the clicking sound when i put them back but still all that does is either make my valve more sticky

- Trumpet valves have metal or plastic tabs that fit into grooves on the casing. They keep the valve in allignment. It sounds like the tabs on your horn could be broken. I suggest letting a repair shop do the work.

- Q: I was diagnosed with Mitral Valve prolapse...I'm 21, 5.5 tall and 130lbs, I had a healthy lifestyle...my doctor said that my case isn't really sever..but i'm taking medications to keep it this way...something i cannot ask my doctor about, would intercourse be harmful to me? and how should I deal with it??? is it okay for me to have children in the future? and could my MVP be cured without surgery??

- good blood does not mix with bad blood. The values have nothing to do with that as the two sides of the heart are separate. With Mitral valve incompetence or prolapse, the valve does not close like it is suppose to. That allows back flow of blood. If bad enough, the treatment is a valve replacement. With Mitral valve stenosis, the valve does not open like it is suppose to. That prevents flow through the valve. The treatment is a valve replacement or sometimes a simple cut in the valve to relieve the stenosis can be done. Either way, if bad enough, surgery is needed, not pills.

- Q: this question is related to Ball valves, In actuated valve for the selection of actuator we need differential pressure across the valve so I wanted to know that what is meant by differential pressure?

- differential pressure is simply having a different pressure each side of the valve. In this case I think that means you need a difference in pressure to move the ball closing the valve.

- Q: I have a 97 ranger 4.0L that takes 10w-30 and I'm going to be changing the oil soon. It has some valve clatter I'm just wondering if I can use a thicker oil such as 15w-30 or maybe a 10w40?

- I wouldn't go any thicker than 10w-40. I have seen 20w-50 in the parts stores, but this will put a lot of strain on the oil pump. You may regret it down the road, and it's just a little bit of noise. Good luck.

- Q: I have varicocele and varicose veins. Both conditions are caused by vein valves becoming damaged or defective. My question is, is this a sign of more serious problems?Thank You

- No it seems to be genetic. The valves just aren't doing thier job and allows some blood to flow backwards . They are unslightly.The place varicose veins is deadly serious is the back of your throat. They are caused by scaring of the liver generally by alcholism

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 350 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords