Quick Details

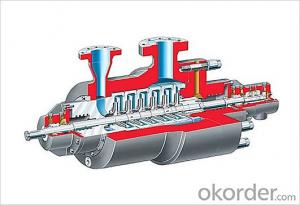

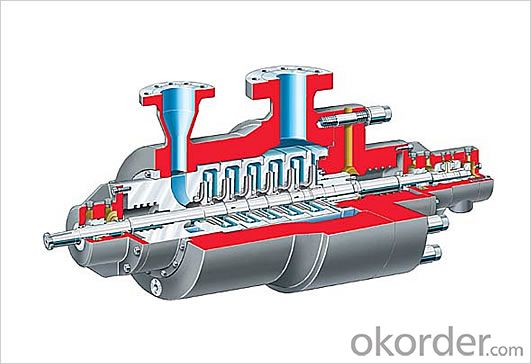

Model Number: YQ NW high flow high pressure water pump

Theory: Centrifugal Pump

Structure: Single-stage Pump

Usage: Water

Power: Electric

Standard or Nonstandard: Standard

Fuel: Diesel

Pressure: Low Pressure

Application: Sewage

Certification: ISO

Color: any

MOQ: 1set

OEM: OK

Applications: power plant

Flow: 36-182 m3/h

Head: 130-230 m

Power: 30 to 160 kw

Caliber: 80-150 mm

Speed: 2950 r/min

Packaging & Delivery

Packaging Details: high flow high pressure water pump packing: Standards exporting wooden case Delivery Detail: Within 7-10days for high flow high pressure water pump Specifications

high quality high flow high pressure water pump

Flow: 36-182 m3 / h

Head: 130-230 m

Power: 30 to 160 kw

Caliber: 80-150 mProduct Description

Supply new product industrial high quality high flow high pressure water pump

NW model with thin pumps, used for low 125000 kw-300000 kw power plant coal conveying low-pressure heater drain, the temperature of the medium in addition to 150-nw-90 x 2 more than 130 °C, the rest of the model are more than 120 °C for models. The series pump cavitation performance is good, suitable for the low NPSH working conditions of work.

Supply new product industrial high quality high flow high pressure water pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: okay i just put a new camshaft in my truck and before my water pump seemed to work but it leaked a little bit but my truck never got hot well i drove it a little bit after puting in the new camshaft and the top radiator hose and heater hose was warm but the bottom radiator hose was cold so i think my water pump went out but not to sure thanks to any answers

- when your water pump goes out, either it will leak from the weep holes which are the holes drilled in the pump by the manufacturer or around the pulley. If that is happening then its your pump. The other thing to check would be your thermostat, check this by turning your truck on and leaving the lid of the radiator. check the temperature of the water in the radiator with your finger if it warms up in ten minutes then its not your thermostat, if the water level goes down ( like lack of water) then its the pump.

- Q: I did change water pump before but not on wv beetle?

- These waterpumps do tend to go bad early - fault of crappy plastic impeller. Make sure to get a pump with a METAL impeller when you change it. They are available online. Also do the timing belt at the same time - saves you labor because you have it apart already to do the pump. Also you need to check out 2 forums:

- Q: I'm planning to install a water pump using electric generator from a very long distance going up from a cliff

- if it is powerful enough to power the pump then yes.

- Q: Got pump ready and will not pump water. Have tried all things suggested to prime but will not pump water

- You prime the gas with gasoline and the water pump is primed with water. The water pump needs a stop valve in the intake so you can add water and it will not run out. Once the impeller is full and the pump is running it should pump OK.

- Q: belt removal mercury cruiser water pump?

- The pump bracket pivots that allows the belt to be removed. I've seen a few where the alternator belt is over the top of the water pump belt, so you have to remove it first. Actually a pretty easy job.

- Q: they say a water pump going bad is supposed to weep out of that hole....Yet I see that a new water pump kit has two gaskettes.some o rings....is it likely that it can leak from these sources and still not come out the weep hole?They talk about berring that could go bad or seals gone bad...does this occure in the area that gets inserted into the engine( the turbine portion of the pump)if you had to guess..where is the most likely area for a water pump to fail...if seems like I have wetness off to the left( back toward the firewall) and less off to the right( front of the car)..more off the left..it is very subtile off the right.I don't see anything coming out of the weep hole..BUT the weephole is directly on top( dead center)and back towards the engine in this model. I have the car jacked up on the passengers side/next to the wheel wellso the fluid is most likely to flow backwards toward the drivers side.

- The water pump can go bad in other ways that means it will not leak. But it will come apart in side and will not pump water. The only way to check it is to use a pressure checker. Put a light pressure on the cooling system. As the engine runs the water pressure should build up to operation tempter. Without over hearting. If the pressure build us to fast. The temp stat is stuck closed. If their is little pressure build up there is a leak in the system. The other way is to start a cold engine and watch the water in the radiator. It should start moving thought the system when the t-stat up up. If the pump was not leaking at the gasket. The seal can go bad. The is a weep hole on the bottom as well on most water pump. It could a heater line or the a hose or steel tub that cool the throbbed or a intake gasket. It could be a head gasket as well. Since you didn't give the make and model. It is hard to pin point the leak to one area.

- Q: I replaced the water pump on my 2001 dodge dakota and I still have a leak coming from somewhere. I don't know if i put the bolts in the wrong holes or what. Some bolts were long and some were short. Is there a diagram that shows where which bolts go where?

- 2001 Dodge Dakota Water Pump

- Q: 93 Cutless Sierra FWD

- For a 2.2 4 cylinder read below: Disconnect battery ground cable, then drain cooling system. Remove serpentine drive belt, then the alternator and bracket. Remove water pump pulley attaching bolts, then remove the pulley, Fig. 20. Remove water pump attaching bolts, then the water pump. Reverse procedure to install. For a 3.3 6 cylinder read below: Disconnect battery ground cable. Drain cooling system, then remove serpentine drive belt. Remove lower radiator hose and heater hose at pump. Remove water pump pulley attaching bolts. Long bolt is removed through access hole located in the body side rail. Remove water pump pulley. Remove water pump attaching bolts, then the water pump, Fig. 15. Reverse procedure to install, torquing bolts to specifications Hope this was helpful!

- Q: i have a 1991 Jeep Cherokee, started overheating last week, i flushed out the radiator with water, i replaced the thermostat, overheated again, i felt the top radiator hose it was cold. so i replaced the water pump. still overheated. every time i drain the system when i refill it i had red to fill the radiator and reservoir, leave the radiator cap off, then start the engine and turn the heat on max, the radiator burps the air bubble out, then the coolant level in the radiator starts going up and down, my thermostat is rated at 195, when the guage hits 210 hot coolant sprays out of the radiator, but the top radiator hose is cold, what am i doing wrong? is there air still trapped in that top radiator hose?

- id say its the radiator after all what ya replaced. have it checked out at a shop. before ya do though ya might do a complete flush of the motor and the cooling system. might be a blockage in a water jacket in the motor. ya can buy the flush kit at any parts store, its simply a T that ya splice into on of the heater core hoses,hook up a water hose,turn heater on, and wait with the engine running. if theres any blockage it will spit and sputter till its pushed out with the water pressure. let it idle till clear water comes out then drain and add coolant. try this first with water only and if it doesnt solve your problem id say ya need a radiator.

- Q: What is the average life of a water pump in a car?

- to many factors to consider such as: materials used for pump, pump design, the engine operator's driving habits. You could have had the wrong belt put on and that would effect pump life. There are just to many variables. I'd say over 60,000 easy. Most pumps come with LLT Warranties b/c you should only have to replace one once.

Send your message to us

Supply new product industrial high quality high flow high pressure water pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords