Steel rail high quality for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

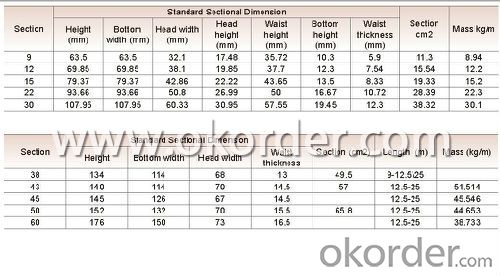

Specifications of High Quality Steel Rail

Product Name: High Quality Steel Rail

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

Applications of High Quality Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of High Quality Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Invoicing on theoretical weight or actual weight as customer request

8. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of High Quality Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: Can steel rails be reused in track maintenance projects?

- Yes, steel rails can be reused in track maintenance projects. Railway tracks have a long lifespan, and when they reach the end of their life cycle, they can be replaced with new rails. However, not all rails need to be completely replaced. Often, sections of the track may only require maintenance or repairs, and in such cases, the existing steel rails can be reused. Railway companies usually inspect the condition of the rails to determine if they can be reused. If the rails are still in good condition, they can be removed, refurbished, and then reinstalled in the areas that require maintenance. This process involves cleaning, straightening, and re-welding the rails as necessary to ensure they meet the required safety standards. Reusing steel rails in track maintenance projects provides several benefits. Firstly, it helps reduce costs as purchasing new rails can be expensive. Additionally, reusing steel rails is an environmentally friendly practice, as it reduces the demand for new materials and minimizes waste. Overall, steel rails can certainly be reused in track maintenance projects, provided they are in good condition and meet the required safety standards. This practice not only saves costs but also supports sustainability in the railway industry.

- Q: Are steel rails used in other industries besides railways?

- Yes, steel rails are used in other industries besides railways. They are commonly used in construction, mining, and manufacturing industries for applications such as crane rails, conveyor systems, and structural support.

- Q: What are the consequences of a cracked steel rail?

- A cracked steel rail can have several significant consequences. Firstly, it can compromise the structural integrity of the rail, leading to potential derailments or accidents. The crack can grow over time due to the continuous stress and load on the rail, eventually resulting in a complete failure. This poses a serious safety risk to trains, passengers, and railway workers. Secondly, a cracked rail can cause disruptions in train services. When a crack is detected, immediate action needs to be taken to repair or replace the damaged rail. This requires shutting down the affected section of the track, which can result in delays and cancellations, inconveniencing passengers and affecting the efficiency of the transportation system. Furthermore, a cracked steel rail can significantly increase maintenance and repair costs for railway companies. Regular inspections and maintenance are necessary to identify and address these issues promptly. If left unattended, the crack can propagate, requiring more extensive repairs or even the complete replacement of the rail. These expenses not only affect the railway company's budget but can also result in higher fares for passengers or increased financial strain on public transportation systems. Additionally, a cracked rail can negatively impact the reputation and public trust in the railway industry. If accidents or incidents occur due to neglected or undetected rail cracks, it can lead to public outrage and loss of confidence in the safety measures implemented by railway companies. This can have far-reaching consequences, including decreased ridership and lower public support for investments in the rail infrastructure. In summary, the consequences of a cracked steel rail include safety risks, disruptions in train services, increased maintenance costs, and potential damage to the reputation of the railway industry. Therefore, it is crucial to prioritize regular inspections, prompt repairs, and investment in infrastructure to prevent and address rail cracks effectively.

- Q: How much do steel rails weigh?

- The size and type of steel rails can lead to variations in their weight. Typically, a standard steel rail employed in railway tracks has a weight of approximately 50 kilograms (110 pounds) per meter. Nevertheless, this weight may slightly differ based on factors like the rail profile, grade, and manufacturer's specifications. It is crucial to mention that longer rails, as seen in high-speed rail lines, can have a significantly higher weight due to their extended length.

- Q: What are the common measures to prevent steel rail theft?

- Common measures to prevent steel rail theft include: 1. Installing security cameras and surveillance systems along rail tracks to deter potential thieves and capture any suspicious activity. 2. Increasing patrols and security presence in high-risk areas to discourage theft attempts and respond quickly if any theft is reported. 3. Implementing advanced technology such as GPS tracking systems and sensors on the rails to monitor their location and detect any unauthorized movement or tampering. 4. Marking the rails with unique identification codes or engraving the rail company's logo, making it difficult for thieves to sell stolen rails and easier to identify stolen property. 5. Establishing partnerships and communication channels with local law enforcement agencies to share information, report suspicious activities, and coordinate efforts to combat rail theft. 6. Conducting regular inspections and maintenance checks on rail infrastructure to detect any signs of tampering or attempted theft. 7. Raising awareness among railway staff, employees, and the public about the consequences and illegality of rail theft, encouraging them to report any suspicious behavior promptly.

- Q: How are steel rails protected from fire hazards?

- Steel rails are protected from fire hazards through several methods. One common method is the application of fire-resistant coatings or paints on the surface of the rails. These coatings act as a barrier, preventing the steel from coming into direct contact with flames or high temperatures. Additionally, various fire suppression systems, such as fire extinguishers or sprinklers, are installed near rail tracks to quickly extinguish any fire incidents. Regular inspections and maintenance procedures also play a crucial role in identifying potential fire hazards and taking necessary preventive measures.

- Q: Are steel rails used in historical railway preservation?

- Yes, steel rails are commonly used in historical railway preservation. They are preferred for their durability and strength, making them suitable for preserving the authenticity and functionality of historical railway tracks. Steel rails also provide a smooth and stable ride for historical trains, ensuring a safe and enjoyable experience for visitors.

- Q: What is the impact of extreme temperatures on steel rails?

- Steel rails can be significantly affected by extreme temperatures, causing various problems. When exposed to high temperatures, steel rails expand and can experience thermal buckling, which can lead to bending, warping, or even breaking. This poses a serious safety risk for trains and other vehicles that rely on the rail system. Conversely, extremely cold temperatures can cause the steel rails to contract, resulting in gaps between the rails. These gaps can lead to track buckling, where the rails lift or shift out of alignment. As a result, derailments or other accidents can occur, jeopardizing the safety and reliability of the rail infrastructure. Furthermore, extreme temperatures can gradually impact the structural integrity of steel rails over time. Repeated exposure to extreme heat or cold can cause fatigue and stress in the steel, resulting in cracks, fractures, or other forms of degradation. This compromises the strength and durability of the rails, requiring frequent inspections, maintenance, and potentially expensive replacements. To mitigate the impact of extreme temperatures on steel rails, various measures are implemented. For example, rail sections may be designed with expansion joints to accommodate thermal expansion and contraction. Additionally, rail materials with higher resistance to temperature changes, such as alloyed steels, can be used to enhance the rail's ability to withstand extreme conditions. Regular monitoring of rail temperatures and the implementation of maintenance and repair protocols are also crucial in identifying and addressing potential issues before they escalate into safety hazards. In conclusion, extreme temperatures can have detrimental effects on steel rails, leading to thermal buckling, track buckling, and structural degradation. These effects pose serious safety risks and necessitate careful engineering, monitoring, and maintenance to ensure the reliability and longevity of rail infrastructure.

- Q: Can steel rails be customized for specific rail applications?

- Yes, steel rails can be customized for specific rail applications. Steel rails are manufactured in various sizes and specifications to meet the specific requirements of different rail applications. Different rail applications, such as heavy-haul freight, high-speed passenger, tramways, and light rail, have different demands in terms of load capacity, durability, and track geometry. To meet these specific requirements, steel rails can be customized in several ways. First, the size and weight of the rail can be adjusted to accommodate different loads and traffic volumes. For example, heavy-haul freight rails are typically larger and heavier to withstand the increased loads and stresses. Additionally, the steel composition and quality can be modified to enhance the durability and longevity of the rails. Rail manufacturers can use different grades of steel and apply specific heat treatments to improve the strength and resistance to wear and fatigue. Furthermore, the geometry of the rail can be tailored for specific applications. This includes adjusting the rail profile, such as the head width, height, and gauge, to ensure proper alignment, stability, and compatibility with the rolling stock. Overall, steel rails can be customized to meet the specific requirements of different rail applications in terms of size, strength, durability, and geometry. This allows for optimal performance and safety in various rail systems around the world.

- Q: What are the safety guidelines for working on steel rails?

- The safety guidelines for working on steel rails include wearing appropriate personal protective equipment (PPE) such as safety glasses, hard hats, and steel-toed boots, maintaining a safe distance from moving trains and equipment, using caution when stepping on or off the rails, and following proper procedures for working in confined spaces or at heights. It is also essential to be aware of and adhere to any specific safety protocols and guidelines provided by the railway company or relevant regulatory authorities.

Send your message to us

Steel rail high quality for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords