Steel Fram Formworks Used for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork GK120 Description

There is a prizing part designed in the corner, which can help to position and remove formwork easily.The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

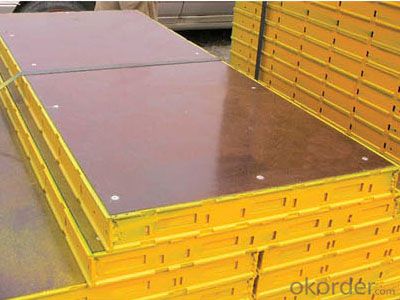

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120Specifications

Steel Frame Formwork GK120 is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the Steel Frame Formwork GK120 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: How does steel frame formwork differ from traditional formwork systems?

- Steel frame formwork differs from traditional formwork systems in several ways. Firstly, steel frame formwork is made of steel, which makes it more durable and long-lasting compared to traditional formwork systems that are typically made of wood. This increased durability allows for multiple uses and reduces the need for frequent repairs or replacements. Additionally, steel frame formwork is easier to assemble and disassemble, making it more efficient and time-saving. It also provides greater flexibility in terms of adjustments and modifications during the construction process. Overall, steel frame formwork offers better strength, durability, efficiency, and flexibility compared to traditional formwork systems.

- Q: How does steel frame formwork ensure proper curing of concrete?

- Steel frame formwork ensures proper curing of concrete in several ways. Firstly, the steel frame provides a strong and rigid structure that holds the concrete in place during the curing process. This prevents any movement or deformation of the concrete, allowing it to set and harden properly. Secondly, steel frame formwork is designed with various features that promote proper curing. These features include built-in water channels and drainage systems that allow for the controlled and efficient removal of excess water from the concrete. This helps to prevent the formation of voids or weak spots in the cured concrete. Additionally, the steel frame formwork can be easily insulated to maintain a consistent temperature during the curing process. This is important as temperature fluctuations can negatively affect the strength and durability of the concrete. By providing insulation, the steel frame formwork helps to create ideal curing conditions and ensures that the concrete cures uniformly. Furthermore, steel frame formwork allows for easy access to the concrete surface, which is essential for proper curing. It enables workers to monitor the curing process, perform necessary inspections, and make any adjustments if needed. This ensures that the concrete is curing correctly and allows for any issues to be addressed promptly. Overall, the use of steel frame formwork in concrete construction plays a crucial role in ensuring proper curing. It provides a stable and secure structure, facilitates efficient water removal, allows for temperature control, and enables easy access for monitoring and inspection. These factors combined contribute to the production of high-quality and durable concrete structures.

- Q: How does steel frame formwork ensure a smooth concrete finish?

- Steel frame formwork ensures a smooth concrete finish by providing a rigid structure that holds the concrete in place during the pouring and curing process. The steel frame is designed to be dimensionally stable and resistant to warping, ensuring that the formwork maintains its shape and prevents any deformation or movement of the concrete. This stability allows for consistent and even distribution of the concrete, resulting in a smooth and uniform surface finish. Additionally, steel formwork can be customized with various surface treatments, such as coatings or linings, to further enhance the smoothness of the concrete finish.

- Q: What are the key considerations for selecting the appropriate steel frame formwork supplier for international projects?

- When selecting the appropriate steel frame formwork supplier for international projects, there are several key considerations that should be taken into account. Firstly, it is important to assess the supplier's experience and track record in working on international projects. This includes evaluating their previous projects, particularly those that are similar in scale and scope to the project at hand. A supplier with a proven track record in successfully delivering international projects will likely have the necessary expertise and understanding of the specific requirements and challenges that may arise. Secondly, it is crucial to consider the supplier's ability to meet international standards and regulations. Different countries may have varying building codes and regulations that need to be adhered to, so it is essential that the supplier has experience in complying with these standards. This can help to ensure that the steel frame formwork supplied is of high quality and meets all necessary safety requirements. Additionally, the supplier's capacity to handle logistics and transportation for international projects should also be taken into account. This includes evaluating their ability to deliver the formwork to the project site in a timely manner, as well as their understanding of any customs and import/export requirements that may be involved. A supplier with a well-established network and efficient logistical capabilities can help to minimize delays and ensure smooth operations throughout the project. Furthermore, it is important to consider the supplier's after-sales support and technical assistance. International projects may require troubleshooting and technical guidance, so it is crucial that the supplier offers reliable support and assistance throughout the project duration. This can include providing training for onsite personnel, offering prompt responses to queries, and having a dedicated team to handle any issues that may arise. Lastly, the cost-effectiveness of the supplier's offerings should be evaluated. While it is essential to prioritize quality and reliability, it is also important to ensure that the supplier's pricing is competitive and aligns with the project's budget. This can be done through requesting detailed quotations and comparing them with other suppliers in the market. In conclusion, selecting the appropriate steel frame formwork supplier for international projects requires careful consideration of factors such as experience, compliance with international standards, logistical capabilities, after-sales support, and cost-effectiveness. By thoroughly assessing these key considerations, project stakeholders can make an informed decision and choose a supplier that is best suited to meet the project's requirements.

- Q: How does steel frame formwork handle the placement of retaining walls and earthworks within the concrete structure?

- The utilization of steel frame formwork is an adaptable and effective approach for managing the positioning of retaining walls and earthworks in a concrete structure. This method involves the use of steel frames that are easily adjustable and can be tailored to meet the specific requirements of the project. In relation to retaining walls, steel frame formwork offers a robust and long-lasting support system. The design of the steel frames is intended to withstand the pressure exerted by the soil and provide stability during the process of pouring and curing the concrete. This guarantees that the retaining wall can endure lateral forces and maintain its shape and integrity over time. Furthermore, steel frame formwork enables flexibility in the design and construction of retaining walls. The frames can be effortlessly modified to accommodate varying heights and slopes, allowing for the creation of walls with different inclinations. This is particularly advantageous in situations where the retaining wall needs to be constructed on uneven terrain or where specific architectural or engineering requirements are present. Regarding earthworks, steel frame formwork provides a secure and stable platform for placing the concrete. The frames are designed to support the weight of the concrete and provide a level surface for pouring and spreading the material. This ensures that the concrete is evenly distributed and properly compacted, resulting in a durable and resilient structure. Moreover, steel frame formwork facilitates efficient and cost-effective construction of earthworks. The frames can be easily assembled and disassembled, making them ideal for projects that require frequent repositioning or where time is of the essence. Additionally, the steel frames can be reused multiple times, reducing the need for excessive materials and minimizing waste. Overall, steel frame formwork is a dependable and efficient method for managing the placement of retaining walls and earthworks in a concrete structure. Its strength, flexibility, and cost-effectiveness make it a preferred choice for numerous construction projects.

- Q: Can steel frame formwork be easily adjusted or modified during the construction process?

- Steel frame formwork offers the flexibility and convenience of being easily adjusted or modified throughout the construction process. These systems are designed to be adaptable, allowing for easy changes as per the construction needs. The steel frames can be dismantled, repositioned, or extended effortlessly to accommodate any alterations in the structure's design or dimensions. Moreover, the formwork panels utilized in steel frame systems are often constructed from lightweight materials like plywood or steel sheets, which can be easily cut or reshaped to meet specific requirements. This adaptability and ease of adjustment make steel frame formwork the preferred choice for construction projects that involve expected modifications or changes.

- Q: What are the key considerations for selecting the appropriate steel frame formwork contractor?

- When choosing a steel frame formwork contractor, there are several important factors to consider. These factors include the contractor's experience and expertise, their reputation and track record, their commitment to safety, their pricing and value for money, and their ability to meet project deadlines. First and foremost, it is crucial to assess the contractor's experience and expertise in steel frame formwork. This can be accomplished by reviewing their previous projects, as well as their qualifications and certifications. A contractor with extensive experience in this field will possess the necessary skills and knowledge to handle the job efficiently and effectively. Next, it is essential to carefully evaluate the contractor's track record and reputation. This can be done by checking references and reading reviews or testimonials from past clients. A contractor with a solid track record and positive reputation is more likely to deliver high-quality work and provide exceptional customer service. Safety is another critical consideration when selecting a steel frame formwork contractor. It is important to ensure that the contractor has a strong safety record and adheres to all necessary safety protocols. This can be determined by reviewing their safety certifications and inquiring about their safety procedures and training programs. Pricing and value for money are also significant factors to consider. While finding a cost-effective option is natural, it is equally important to consider the quality of work and materials provided by the contractor. It is advisable to obtain multiple quotes and compare them, taking into consideration the contractor's experience, reputation, and the scope of the project. Lastly, the contractor's ability to meet project deadlines should not be overlooked. It is crucial to ascertain that the contractor has the capacity and resources to complete the project within the specified timeframe. This can be determined by discussing project timelines and deadlines with the contractor and evaluating their project management capabilities. In conclusion, choosing the appropriate steel frame formwork contractor necessitates careful consideration of their experience, track record, commitment to safety, pricing, and ability to meet project deadlines. By evaluating these key factors, you can make an informed decision and select a contractor that will deliver high-quality work and meet your project requirements.

- Q: Steel frame wood template defects

- And out of the wall also need high cost in the batch. Turnover number is not much

- Q: Can steel frame formwork be used for the construction of parking structures?

- Yes, steel frame formwork can be used for the construction of parking structures. Steel frame formwork is a versatile and durable system that provides the necessary support and structure during the construction process. It offers the advantage of being able to handle heavy loads and withstand the pressures and stresses associated with parking structures. Additionally, steel frame formwork allows for easy and efficient assembly and disassembly, making it a practical choice for construction projects that require speed and flexibility. The use of steel frame formwork in parking structure construction can result in a strong and reliable final product that meets the required safety standards.

- Q: What are the different types of safety nets and fall protection systems used with steel frame formwork?

- To ensure worker safety, various safety nets and fall protection systems are commonly employed alongside steel frame formwork. These systems serve to prevent falls from heights and establish a secure working environment. Among the safety nets utilized with steel frame formwork, the perimeter safety net is prevalent. It encompasses the work area's perimeter, capturing any falling objects and preventing their descent to the ground or workers below. Typically crafted from robust materials like high-strength nylon or polypropylene, the perimeter safety net is engineered to withstand substantial impacts. Its presence is vital in averting accidents and injuries caused by falling debris. Another fall protection system employed with steel frame formwork is the safety harness and lanyard system. This system comprises a comprehensive body harness worn by workers, which connects to an anchorage point using a lanyard. By distributing the force of a fall across the worker's body, the harness reduces the risk of injury. Lanyards, usually composed of resilient materials such as nylon or polyester, are designed to absorb fall energy. In addition to safety nets and harness systems, guardrails find common usage in conjunction with steel frame formwork. These barriers encircle the work area's perimeter, preventing inadvertent worker falls. Constructed from durable materials like high-strength steel or aluminum, guardrails are engineered to withstand significant impacts. They serve as a physical barrier, continuously reminding workers of the potential hazards associated with working at heights. Lastly, safety platforms are frequently deployed alongside steel frame formwork to provide workers with stable and secure surfaces. Fabricated from steel or aluminum, these platforms are easily installed and removed. By offering a level area for workers to stand on while operating at heights, safety platforms reduce the risk of slips and falls. In conclusion, safety nets, harness systems, guardrails, and safety platforms constitute the various fall protection systems employed alongside steel frame formwork. These systems play a crucial role in averting falls from heights and ensuring workers' safety on construction sites.

Send your message to us

Steel Fram Formworks Used for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches