Steel-frame Formwork System Link Part

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

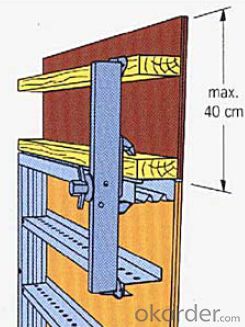

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for both standard and non-standard concrete shapes?

- Yes, steel formwork can be used for both standard and non-standard concrete shapes. Steel formwork offers flexibility and customization options, allowing it to be easily adapted to various shapes and sizes required for concrete structures. Its strength and durability make it suitable for shaping and supporting concrete in both standard and non-standard designs.

- Q: How is steel formwork installed?

- Steel formwork is installed by first preparing the construction site, ensuring a level surface and proper alignment. The steel panels are then assembled and secured together using bolts or clamps to create the desired form shape. Reinforcement bars and spacers are placed within the formwork to maintain the required concrete thickness. Finally, the formwork is braced and supported using props or scaffolding to ensure stability during the concrete pouring process.

- Q: Are there any specific quality control measures for steel formwork construction?

- Steel formwork construction has specific quality control measures in place to guarantee compliance with standards and specifications, as well as to ensure its safety and reliability in construction projects. An important quality control measure involves inspecting the steel formwork materials prior to their use. This includes checking for defects, such as cracks, rust, or other damage, that may compromise the formwork's integrity and strength. Additionally, the materials must be checked for correct dimensions and smoothness to ensure proper fit and a smooth surface finish. Another measure involves inspecting the steel formwork during and after the construction process. This entails verifying that the formwork is properly assembled and secured, with all connections and joints aligned and tightened correctly. Furthermore, the formwork must be checked for signs of deformation, like bending or twisting, which could compromise its structural integrity. Apart from inspections, quality control measures also include testing the steel formwork to assess its strength and durability. This may involve conducting load tests to determine its maximum load capacity and evaluating its resistance to environmental factors such as corrosion, fire, and moisture. Documentation and record-keeping are also crucial quality control measures for steel formwork construction. This involves maintaining detailed records of inspections, tests, and any repairs or modifications made to the formwork. Such documentation ensures traceability of the construction process and allows for auditing if necessary. In conclusion, these quality control measures are vital to ensure that steel formwork construction is of high quality, meets the required standards, and provides a safe and reliable support system for concrete during construction.

- Q: How does steel formwork affect the overall project budget and cost control?

- Steel formwork has the potential to significantly impact the overall project budget and cost control. To start with, steel formwork offers a durable and reusable alternative to traditional timber formwork. Although the initial investment in steel formwork may be higher, it can be utilized for multiple projects, resulting in long-term cost savings. Moreover, steel formwork provides greater accuracy and precision, leading to reduced material wastage and labor costs. The precise dimensions and alignment offered by steel formwork contribute to improved quality and faster construction, thereby reducing the overall project duration and associated expenses. Additionally, steel formwork is renowned for its strength and stability, enabling higher concrete pouring rates and larger pour sizes. This enhances productivity and reduces the necessary labor, positively impacting the project budget. Furthermore, steel formwork necessitates less maintenance and repairs, thus decreasing ongoing expenses. Unlike timber formwork, steel formwork is not susceptible to rot, warping, or damage caused by insects, weather, or repetitive use. The longevity and durability of steel formwork help minimize replacement and repair costs. However, it is crucial to consider that the installation and removal of steel formwork may require specialized skills and equipment. This can affect labor costs and may necessitate additional training or the hiring of experienced workers, which should be taken into account when planning the project budget. In conclusion, the utilization of steel formwork can have a positive impact on the overall project budget and cost control due to its durability, reusability, accuracy, efficiency, and reduced maintenance requirements. Although the initial investment may be higher, the long-term benefits, such as reduced material wastage, improved quality, increased productivity, and decreased repair costs, make steel formwork a cost-effective choice for construction projects.

- Q: What are the considerations when designing steel formwork for water tanks?

- When designing steel formwork for water tanks, there are several important considerations that need to be taken into account. These considerations include structural integrity, corrosion resistance, water tightness, and ease of construction. Firstly, structural integrity is crucial when designing steel formwork for water tanks. The formwork needs to be able to withstand the weight of the water and any additional loads such as surcharge or seismic forces. It is important to calculate the required thickness and reinforcement of the steel plates to ensure that they can safely support the weight of the water and prevent any structural failure. Secondly, corrosion resistance is another key consideration. Water tanks are constantly exposed to moisture, which can lead to the formation of rust and corrosion on the steel formwork. To mitigate this, it is important to use corrosion-resistant steel or apply protective coatings to the formwork. These coatings should be able to withstand the constant exposure to water and prevent any degradation of the steel. Water tightness is another crucial consideration when designing steel formwork for water tanks. The formwork needs to be able to retain the water without any leakage. This requires careful design and construction techniques such as proper sealing joints, welding, and the use of waterproofing materials. It is essential to ensure that there are no gaps or weak points in the formwork that could lead to water leakage. Lastly, ease of construction is an important consideration when designing steel formwork for water tanks. The formwork should be designed in such a way that it can be easily assembled and disassembled, allowing for efficient construction and maintenance. It is important to consider factors such as modular construction, ease of access for workers, and the use of appropriate lifting equipment. In conclusion, when designing steel formwork for water tanks, it is important to consider factors such as structural integrity, corrosion resistance, water tightness, and ease of construction. By carefully considering these factors, one can ensure the durability, functionality, and longevity of the water tank.

- Q: How does steel formwork affect the construction timeline?

- Steel formwork can have a significant impact on the construction timeline in both positive and negative ways. One of the main advantages of using steel formwork is its durability and strength. Unlike traditional wooden formwork, steel formwork can withstand multiple uses without losing its structural integrity. This means that it can be reused many times, reducing the time and effort required to set up formwork for subsequent construction phases. Additionally, steel formwork allows for faster assembly and disassembly, which can help to expedite construction timelines. Furthermore, steel formwork provides a high level of accuracy and consistency in shaping concrete structures. The precise dimensions and smooth finish achieved with steel formwork ensure that the construction process proceeds smoothly without any delays caused by rework or adjustments. This can lead to faster completion of construction projects. On the other hand, steel formwork can also introduce certain challenges that may affect the construction timeline. Firstly, steel formwork is generally heavier and requires more effort to transport and handle compared to other types of formwork. This may slow down the overall construction process, especially if there are limitations in terms of available equipment or labor. Additionally, steel formwork may require additional time for installation and dismantling compared to other formwork systems. The complexity of steel formwork systems and the need for skilled workers to handle them can result in a longer setup and removal time. This can impact the overall construction timeline, particularly when tight deadlines need to be met. In conclusion, steel formwork can have both positive and negative effects on the construction timeline. Its durability, reusability, and accuracy can help expedite the construction process. However, the weight and complexity of steel formwork may introduce additional challenges that can potentially slow down the construction timeline.

- Q: Can steel formwork be used in areas with high seismic vulnerability?

- Yes, steel formwork can be used in areas with high seismic vulnerability. Steel is a strong and durable material that can withstand the forces and vibrations caused by earthquakes. It provides stability and structural integrity to the formwork system, making it suitable for use in seismic-prone regions. Additionally, steel formwork can be designed and reinforced to meet the specific requirements and regulations of the area, ensuring its suitability for use in high seismic vulnerability zones.

- Q: How does steel formwork affect the overall construction timeline?

- Steel formwork can significantly affect the overall construction timeline in several ways. Firstly, steel formwork is known for its durability and strength, allowing for faster and more efficient construction processes. Unlike traditional timber formwork, steel formwork can be reused multiple times, reducing the time and effort required for dismantling and reassembly. This reusability not only saves time but also minimizes the need for additional materials, thereby reducing construction waste and costs. Additionally, steel formwork provides greater flexibility in terms of design and customization. Its versatility allows for complex shapes and structures to be easily created, reducing the need for extensive modifications or adjustments during the construction process. This flexibility not only saves time but also enhances the overall construction efficiency. Moreover, steel formwork offers quicker curing times for concrete, as it provides better temperature and moisture control. This accelerates the process of concrete setting and reduces the time required for form removal. Consequently, the construction timeline is shortened, enabling subsequent construction activities to commence earlier. Furthermore, steel formwork is known for its high load-bearing capacity, enabling multiple floors to be constructed simultaneously. This parallel construction approach can significantly expedite the construction process, thereby reducing the overall timeline. However, it is important to note that while steel formwork offers numerous advantages, its initial setup and installation may require more time compared to other formwork materials. The steel formwork system needs to be properly aligned and secured, which might take longer than setting up traditional timber formwork. However, this initial time investment is often offset by the time saved during subsequent construction stages. In conclusion, steel formwork can have a positive impact on the overall construction timeline. Its durability, reusability, versatility, quicker curing times, and high load-bearing capacity contribute to faster construction processes, reduced material waste, and increased construction efficiency. Despite the initial setup time, the benefits of steel formwork ultimately result in a more streamlined and accelerated construction timeline.

- Q: Can steel formwork be used in seismic zones?

- Yes, steel formwork can be used in seismic zones. Steel is a strong and durable material that can withstand the forces and movements caused by seismic activity. It provides stability and structural integrity to the formwork system, ensuring the safety and effectiveness of the construction process in seismic zones.

- Q: How does steel formwork handle different concrete slump values?

- Steel formwork is a versatile and robust solution that can effectively handle different concrete slump values. Slump refers to the consistency or fluidity of concrete, and it is measured in terms of its workability. Steel formwork is designed to accommodate various slump values due to its inherent strength and durability. Firstly, steel formwork provides excellent support and stability to the concrete during the pouring and curing process. It can withstand the pressure exerted by the wet concrete, regardless of its slump value. The rigid structure of steel formwork ensures that it maintains its shape and integrity, even with high slump concrete. Additionally, steel formwork offers flexibility in terms of adjusting the formwork panels to suit different slump values. The panels can be easily adjusted or repositioned to create the desired shape or size for the concrete structure. This adaptability allows steel formwork to efficiently accommodate varying slump values without compromising the quality or integrity of the final concrete product. Furthermore, steel formwork provides a smooth and even surface finish for the concrete, irrespective of its slump value. The steel panels are precisely manufactured to ensure a consistent and uniform surface finish, enhancing the overall aesthetics of the concrete structure. This is particularly important when dealing with different slump values as it ensures a visually appealing and professional end result. In conclusion, steel formwork is well-equipped to handle different concrete slump values due to its strength, durability, and flexibility. It provides excellent support, stability, and adaptability during the pouring and curing process, resulting in a high-quality finished product. Whether the concrete has a low or high slump value, steel formwork consistently delivers a smooth and visually appealing surface finish, making it a reliable choice for various construction projects.

Send your message to us

Steel-frame Formwork System Link Part

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords