Adjustable Arced Steel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

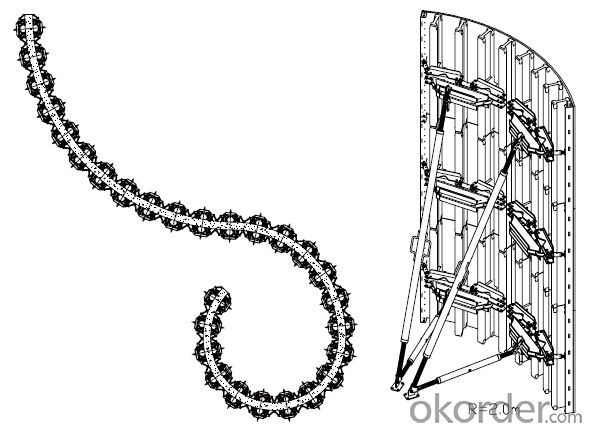

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: Can steel formwork be used for architectural concrete elements?

- Yes, steel formwork can be used for architectural concrete elements. Steel formwork is known for its durability, strength, and versatility, making it suitable for various construction applications, including architectural concrete elements. It provides a smooth and precise finish and can be easily customized to meet specific design requirements. Additionally, steel formwork is reusable, making it a cost-effective choice for architectural projects.

- Q: How does steel formwork prevent concrete mixture separation during pouring?

- In construction projects, steel formwork is employed to create a temporary structure that securely holds the concrete in position until it solidifies and becomes rigid. A significant advantage of utilizing steel formwork is its ability to prevent the concrete mixture from disintegrating while it is being poured. The steel formwork is meticulously designed and assembled to establish a tight enclosure for the concrete, guaranteeing that it maintains its intended shape and texture. It consists of firmly fastened steel panels and frames, which combine to form a sturdy structure. When the concrete mixture is poured into the steel formwork, it is effectively restrained by the formwork walls itself. The steel panels and frames offer a smooth and uniform surface onto which the concrete can be poured, effectively averting any separation or division within the mixture. Moreover, the steel formwork is purposefully constructed with accurately aligned joints and connections, which further prevents any leakage or permeation of the concrete mixture. This ensures the integrity of the concrete, preventing it from breaking down into its constituent materials such as aggregates, cement, and water. Additionally, the steel formwork possesses the capacity to withstand the pressure exerted by the weight of the concrete. This successfully averts any deformation or displacement of the formwork during the pouring process, as such movements could potentially lead to the separation or shifting of the concrete. All in all, the utilization of steel formwork provides a robust and steady structure that effectively prevents the concrete mixture from separating during pouring. It ensures the concrete maintains its desired form and consistency, ultimately resulting in a finished product that is of high quality and durability.

- Q: How are steel formwork systems assembled and disassembled?

- A simple and efficient process is used to assemble and disassemble steel formwork systems. The process begins by erecting the steel panels, which interlock with each other using connecting devices like pins, wedges, or clips. These panels come in various sizes and shapes to meet different construction needs. To assemble the steel formwork system, the panels are aligned and connected based on the desired shape and dimensions of the structure. Pins or wedges are commonly used to secure the panels and prevent movement during concrete pouring. Once the panels are connected, support structures such as walers, props, and braces are installed. Walers are horizontal beams that connect the vertical panels, while props provide additional stability as adjustable vertical supports. Braces help resist lateral forces. During concrete pouring, the steel formwork system holds the wet concrete in place, giving shape and finish to the structure. After the concrete has cured and gained strength, the dismantling process begins. To disassemble the steel formwork system, the props and braces are removed first, followed by the walers. Once the support structures are taken down, the panels can be easily detached by removing the connecting devices. This can be done by pulling out pins or wedges or releasing clips. The disassembly process follows a systematic approach, starting from the top and moving downwards to ensure safety and prevent accidental collapse. It is important to follow safety guidelines and use appropriate tools to avoid damage to the formwork system or injury to workers. In conclusion, steel formwork systems are assembled by connecting panels and installing support structures, while the disassembly process involves removing support structures and disconnecting panels. This systematic approach ensures a safe and efficient construction process, allowing for the reuse of the formwork system in future projects.

- Q: What are the challenges of using steel formwork?

- One of the main challenges of using steel formwork is its high initial cost compared to other types of formwork. Steel formwork also requires skilled labor for its installation and removal, which can increase project expenses. Additionally, steel formwork is heavy and requires special transportation and handling equipment, making it less convenient and cost-effective for small-scale projects. Finally, steel formwork requires proper maintenance to prevent corrosion and ensure its longevity, adding to the overall cost and effort involved in its use.

- Q: How does steel formwork handle different concrete admixtures?

- Steel formwork is highly compatible with different concrete admixtures. The rigid and durable nature of steel allows it to withstand the chemical reactions and physical properties of various admixtures, such as accelerators, retarders, and plasticizers. Steel formwork ensures the proper containment and shaping of the concrete, regardless of the admixtures used, resulting in a high-quality finished product.

- Q: What are the different safety certifications and standards for steel formwork?

- There are several safety certifications and standards for steel formwork used in construction projects. Some of the most common ones include ISO 9001 certification, which ensures quality management systems are in place; OHSAS 18001 certification, which indicates compliance with occupational health and safety standards; and EN 12812 standard, which defines requirements for temporary works equipment such as formwork. Additionally, local building codes and regulations play a crucial role in ensuring the safety of steel formwork installations.

- Q: Can steel formwork be used in industrial construction projects?

- Yes, steel formwork can be used in industrial construction projects. Steel formwork is known for its durability and strength, making it suitable for withstanding the heavy loads and demands of industrial construction. It is also reusable, allowing for cost savings and efficiency in large-scale projects. Additionally, steel formwork provides a smooth finish and precise alignment, ensuring high-quality and accurate construction in industrial settings.

- Q: How does steel formwork contribute to the accuracy of concrete placements?

- Steel formwork contributes to the accuracy of concrete placements by providing a strong and stable structure that holds the concrete in place during the pouring and setting process. The use of steel formwork ensures that the concrete is poured into the desired shape and dimensions, eliminating any potential for deviations or errors. Additionally, the rigid nature of steel formwork prevents any movement or shifting of the concrete, resulting in a more precise and accurate placement.

- Q: How does steel formwork handle different concrete shrinkage characteristics?

- Steel formwork is an effective solution to handle different concrete shrinkage characteristics. Its rigid and sturdy nature allows it to withstand the pressure exerted by concrete shrinkage without deforming or cracking. Additionally, steel formwork can be easily adjusted and reinforced to accommodate varying levels of shrinkage, ensuring the structural integrity of the concrete.

- Q: How does steel formwork handle different concrete setting time requirements?

- Steel formwork is highly versatile and can easily accommodate different concrete setting time requirements. It provides a rigid and sturdy framework that supports the concrete during the setting process. The steel formwork allows for precise shaping and molding of the concrete, enabling it to take various forms and designs. Additionally, steel formwork offers adjustable features, such as adjustable joints and connectors, which allow for quick assembly and disassembly, making it efficient in meeting different concrete setting time requirements. Overall, steel formwork provides a reliable and adaptable solution for handling different concrete setting time requirements.

Send your message to us

Adjustable Arced Steel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords