Steel-frame formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

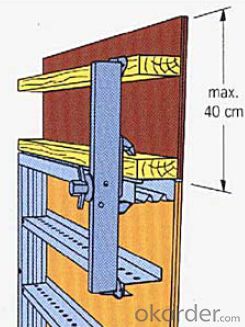

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used in bridge construction projects?

- In bridge construction projects, steel formwork can be utilized. Steel formwork is a temporary structure employed to support and shape the concrete throughout the construction phase. It is extensively applied in diverse construction projects, including bridges. By employing steel formwork, several advantages are obtained in bridge construction, such as enhanced strength, durability, and resistance to deformation. The structure can withstand the weight of the concrete and other construction materials, thereby guaranteeing the stability and integrity of the bridge. Moreover, steel formwork offers flexibility in creating intricate bridge designs, enabling the construction of various bridge types, such as arch bridges, cable-stayed bridges, and suspension bridges. The integration of steel formwork in bridge construction projects aids in simplifying the construction process, enhancing efficiency, and ensuring the quality of the final bridge structure.

- Q: What are the different types of accessories used with steel formwork?

- There are various types of accessories that are commonly used with steel formwork to enhance its functionality and effectiveness in construction projects. Some of the different types of accessories used with steel formwork include: 1. Formwork Wedges: These are small wedges made of steel or plastic that are used to secure the formwork panels together. They help in maintaining the accurate alignment and stability of the formwork system during concrete pouring. 2. Formwork Clamps: Clamps are used to hold the formwork panels in place and prevent any movement or displacement during the pouring and curing of concrete. They are typically made of steel and are available in different sizes and designs to suit various formwork requirements. 3. Formwork Ties: Ties are used to connect the formwork panels and provide structural stability to the formwork system. They can be either steel or plastic and are available in different lengths and types, such as snap ties, wedge ties, and loop ties. 4. Formwork Braces: Braces are used to reinforce and strengthen the formwork system. They are typically made of steel and are used to support the formwork panels and prevent any bending or deformation during the concrete pouring process. 5. Formwork Hangers: Hangers are used to suspend the formwork panels at the desired height and provide support. They are typically made of steel and are adjustable to accommodate different formwork heights and configurations. 6. Formwork Spacers: Spacers are used to maintain the desired spacing between the formwork panels and ensure uniformity in the thickness of the concrete walls or slabs. They are typically made of plastic or steel and are available in various sizes and shapes. 7. Formwork Release Agents: Release agents are used to prevent the adhesion of concrete to the formwork surface. They are applied to the formwork panels before the concrete is poured, allowing for easy removal of the formwork once the concrete has cured. Overall, these accessories play a crucial role in ensuring the stability, alignment, and functionality of steel formwork systems. They contribute to the efficiency and quality of construction projects by providing reliable support and reinforcement to the formwork during the concrete pouring process.

- Q: What are the advantages and disadvantages of the application of the steel formwork and the plywood formwork in the construction?

- From the aspect of Construction: the construction speed of the large steel formwork is fast, the quality effect is good; the wood formwork is assembled slowly, and the bulging phenomenon is easy to occur;

- Q: What are the different types of access solutions available for steel formwork?

- There are several different types of access solutions available for steel formwork, depending on the specific requirements of the construction project. Some of the common access solutions include: 1. Ladder Access: This is the most basic and commonly used access solution for steel formwork. Ladders are attached to the formwork structure, allowing workers to climb up and down easily. Ladder access is simple, cost-effective, and suitable for low-rise structures. 2. Stair Access: For taller structures, stair access is a safer and more convenient option. Stairs can be attached to the steel formwork, providing a stable and secure pathway for workers to move between different levels. Stair access is particularly useful in high-rise buildings or projects with multiple levels. 3. Platform Access: Platforms are often used in conjunction with ladders or stairs to provide a wider working area. These platforms can be fixed or movable, allowing workers to access various parts of the steel formwork system easily. Platforms provide a stable and safe working surface, enhancing productivity and safety on the construction site. 4. Scaffold Access: Scaffold systems are commonly used for construction projects and can also be utilized for accessing steel formwork. Scaffold access provides a flexible and adjustable solution, allowing workers to reach different heights and areas of the formwork structure. Scaffold access is particularly useful for complex projects or projects with irregular shapes. 5. Crane Access: In some cases, large steel formwork panels or structures may require the use of cranes for access. Cranes can lift workers to the desired height, providing a quick and efficient access solution. Crane access is often used for heavy-duty formwork systems or projects with large-scale structures. In summary, the different types of access solutions available for steel formwork include ladder access, stair access, platform access, scaffold access, and crane access. The choice of access solution depends on factors such as the height and complexity of the structure, as well as the specific requirements of the construction project.

- Q: How does steel formwork affect the overall project cost estimation?

- The overall project cost estimation can be significantly influenced by the use of steel formwork. Although steel formwork may have a higher initial cost when compared to materials like timber or plywood, it offers several advantages that can lead to long-term cost savings. To begin with, steel formwork is extremely durable and can be used multiple times. Unlike timber or plywood formwork that may require replacement after a few uses, steel formwork can withstand numerous cycles, reducing the need for frequent replacements. This not only saves on material costs but also reduces the labor and time required for formwork installation and removal. Moreover, steel formwork provides superior quality finishes, resulting in a decreased need for surface treatments or plastering. This saves both material and labor costs associated with finishing work. Furthermore, steel formwork offers greater precision and dimensional accuracy, reducing the need for rework or adjustments during construction. This helps minimize material wastage and saves time and labor costs. In addition, steel formwork is highly resistant to moisture and weathering, allowing it to be used in various weather conditions without compromising its structural integrity. This flexibility enables more efficient construction scheduling, reducing downtime and potential cost overruns. Lastly, steel formwork can support greater concrete pouring heights and pressures, enabling faster construction and increased productivity. This can result in accelerated project timelines and reduced labor costs. In conclusion, while steel formwork may have a higher initial cost, its durability, reusability, improved finishes, precision, resistance to weathering, and ability to support larger concrete pours can lead to significant cost savings in terms of material, labor, and time. Therefore, steel formwork has a positive impact on the overall project cost estimation.

- Q: How does steel formwork accommodate for different concrete curing durations?

- Steel formwork can accommodate for different concrete curing durations by providing a sturdy and durable structure that can support the weight of the concrete during the curing process. The steel formwork is designed to be reusable, allowing for easy removal once the concrete has cured to the desired strength. This flexibility in formwork material enables construction projects to adapt to different curing durations without compromising the structural integrity of the concrete.

- Q: How does steel formwork help in achieving accurate dimensions and shapes?

- Steel formwork helps in achieving accurate dimensions and shapes by providing a strong and rigid structure that holds the concrete in place during the curing process. This prevents any movement or deformation of the concrete, ensuring that it sets in the desired shape and size. The precise fabrication and assembly of steel formwork also allow for easy adjustment and customization, enabling accurate measurements and achieving the desired dimensions of the final structure.

- Q: What are the considerations when designing steel formwork for high-rise buildings?

- When designing steel formwork for high-rise buildings, it is important to consider several key factors: 1. Load-bearing capacity: High-rise buildings experience significant vertical and lateral loads. Therefore, the steel formwork must be able to support the weight of the concrete and any additional loads, such as equipment or workers. 2. Structural stability: The design of the steel formwork should ensure structural stability during the construction process. This involves considering factors like building height, wind loads, and the possibility of earthquakes. Proper bracing and reinforcement are necessary to maintain formwork stability. 3. Durability: High-rise buildings often have longer construction periods, so the formwork must be able to withstand prolonged exposure to concrete, weather conditions, and repetitive use. To enhance durability, the steel formwork should be designed with corrosion-resistant materials and protective coatings. 4. Flexibility and adaptability: High-rise buildings often have complex architectural designs and irregular shapes. Therefore, the formwork system should be flexible and adaptable to accommodate variations in geometry. This allows for efficient construction and minimizes the need for custom-made components. 5. Safety: Safety is of utmost importance when designing steel formwork for high-rise buildings. The formwork should be designed to prevent accidents and ensure the well-being of workers. Safety features such as guardrails, toe boards, and safe access points should be incorporated. 6. Ease of assembly and disassembly: Assembling and disassembling formwork for high-rise buildings can be labor-intensive and time-consuming. To streamline the construction process, the formwork system should have easy-to-use connections, standardized components, and clear assembly instructions. 7. Cost-effectiveness: High-rise construction projects often have limited budgets. Therefore, the design of the steel formwork should take into account its cost-effectiveness. This includes considering the potential for formwork reuse, minimizing the need for additional support structures, and optimizing the use of materials. By carefully considering these factors, designers can ensure that the steel formwork for high-rise buildings is strong, safe, durable, and cost-effective, enabling the successful construction of these complex structures.

- Q: How does steel formwork contribute to the overall structural integrity of the building?

- Steel formwork contributes to the overall structural integrity of the building by providing a strong and durable framework for concrete construction. It ensures accurate and precise alignment of walls, columns, and beams, resulting in a structurally sound and stable building. The steel formwork system is capable of withstanding heavy loads and forces during construction and enhances the overall strength and stability of the structure. Additionally, the use of steel formwork allows for easy and efficient construction, reducing construction time and costs while ensuring high-quality and long-lasting buildings.

- Q: What are the different types of connections used in steel formwork?

- There are several types of connections used in steel formwork, including bolted connections, welded connections, and clamped connections. Bolted connections involve using bolts and nuts to secure the formwork together, ensuring a strong and secure connection. Welded connections involve welding the steel plates or components together, creating a permanent and durable connection. Clamped connections use clamps to hold the formwork in place, providing a quick and adjustable connection method. Each type of connection has its advantages and is chosen based on the specific requirements of the project.

Send your message to us

Steel-frame formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords