Steel-Frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

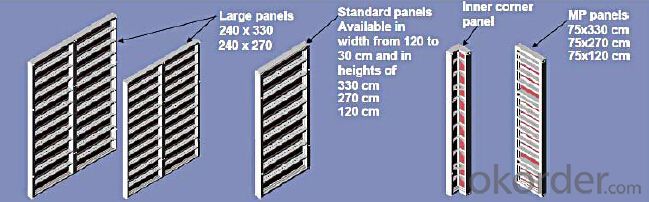

◆ The selection of panels.

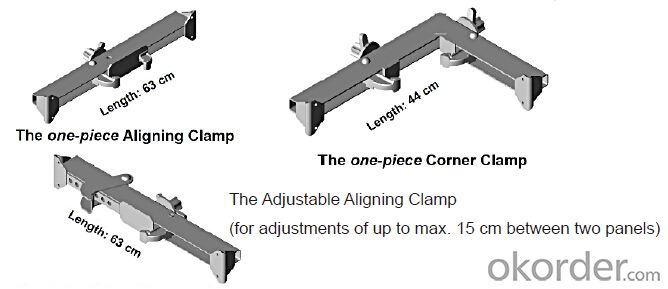

◆ Kinds of panel connectors.

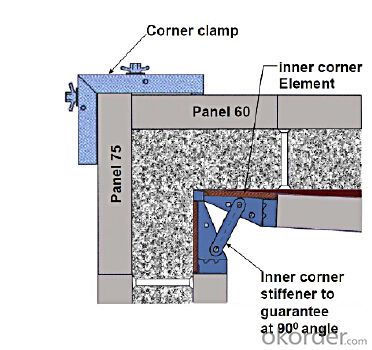

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Is steel formwork suitable for projects with limited construction space?

- Indeed, projects with limited construction space can benefit greatly from the utilization of steel formwork. Renowned for its adaptability and capacity to be tailored to different project specifications, especially those constrained by space restrictions, steel formwork stands as a lightweight and resilient alternative. Its inherent feasibility in terms of assembly, disassembly, and mobility further contributes to optimal space utilization. Moreover, steel formwork guarantees a remarkable level of precision and accuracy, facilitating a seamless and efficient construction process within the confines of limited space.

- Q: What are the common challenges when using steel formwork?

- There are several common challenges that can arise when using steel formwork in construction projects. Firstly, one challenge is the initial cost of steel formwork. Compared to other types of formwork, such as timber or plywood, steel formwork tends to be more expensive. This can be a barrier for contractors or builders with limited budgets or smaller-scale projects. Another challenge is the weight of steel formwork. Steel is a heavy material, and transporting and handling steel formwork can be physically demanding. This can require additional labor and equipment to safely and efficiently move and position the formwork on-site. Durability is also a concern when using steel formwork. While steel is generally a strong and long-lasting material, it can be susceptible to rust and corrosion if not properly protected. Regular maintenance and protective coatings are necessary to ensure the longevity and performance of steel formwork. Moreover, the versatility of steel formwork can be a challenge. Steel formwork is typically prefabricated and designed for specific applications. This means that if there is a need for customization or alterations during the construction process, it may be difficult to modify the steel formwork to meet the new requirements. This can lead to delays or additional costs. Lastly, the complexity of assembly and disassembly can be a challenge with steel formwork. Steel formwork systems often require skilled labor and specific tools for installation and removal. This can add complexity to the construction process and may require additional time and resources. Overall, while steel formwork offers many advantages such as strength and durability, it also presents challenges related to cost, weight, durability, versatility, and assembly. These challenges should be carefully considered and addressed to ensure the successful use of steel formwork in construction projects.

- Q: Are there any environmental considerations when using steel formwork?

- Using steel formwork in construction projects raises several environmental considerations. First and foremost, the production of steel leaves a significant carbon footprint. Greenhouse gas emissions are generated during the extraction and processing of raw materials, such as iron ore and coal. Moreover, the manufacturing process itself requires a substantial amount of energy, further contributing to carbon emissions. In addition, the transportation of steel formwork systems has a negative environmental impact. The movement of heavy steel panels and other components increases fuel consumption and emissions, particularly for long distances. Furthermore, steel formwork is typically non-renewable and non-recyclable. Once it reaches the end of its useful life, it often ends up in landfills, contributing to waste accumulation and environmental pollution. However, it is important to note that steel formwork does have some environmental advantages compared to other materials. For instance, it can be reused multiple times, reducing the need for new materials and minimizing waste generation. Its durability and strength also contribute to a longer lifespan and less frequent replacements, which in turn reduces overall resource consumption. To mitigate the environmental impact of using steel formwork, various measures can be taken. These include optimizing transportation routes to reduce fuel consumption, implementing energy-efficient manufacturing processes, and promoting the recycling of steel formwork components at the end of their life. Additionally, exploring alternative formwork materials, such as recycled or sustainable options, can also help address the environmental considerations associated with steel formwork usage.

- Q: What are the different sizes and dimensions of steel formwork panels?

- Steel formwork panels come in various sizes and dimensions to cater to different construction needs. The sizes and dimensions of steel formwork panels can vary depending on the manufacturer and the specific requirements of a project. However, there are some common sizes and dimensions that are widely available in the market. The standard dimensions of steel formwork panels usually range from 1.2 meters to 2.4 meters in length and 0.6 meters to 1.2 meters in width. These standard sizes are designed to be easily handled and transported on construction sites. Additionally, the thickness of steel formwork panels can vary between 3 millimeters to 6 millimeters, depending on the load-bearing capacity required. Apart from the standard sizes, custom sizes can also be manufactured to meet specific project needs. These custom sizes can be larger or smaller than the standard dimensions, depending on the complexity and scale of the construction project. In terms of weight, steel formwork panels are relatively heavy due to the material's durability and strength. The weight of a steel formwork panel can range from 30 kilograms to 50 kilograms, depending on its size and thickness. Overall, the sizes and dimensions of steel formwork panels can vary to accommodate different construction requirements. It is important to consult with a supplier or manufacturer to determine the most suitable size and dimension for a specific project.

- Q: Can steel formwork be used for precast concrete slabs with openings?

- Yes, steel formwork can be used for precast concrete slabs with openings. Steel formwork offers the flexibility and strength required to create openings in precast concrete slabs, ensuring precise and consistent results. Additionally, the durability and reusability of steel formwork make it a cost-effective choice for such applications.

- Q: Is steel formwork suitable for projects with limited access?

- Yes, steel formwork is suitable for projects with limited access. Steel formwork is known for its strength and durability, allowing it to be easily transported and assembled in confined spaces. Additionally, steel formwork can be customized to fit specific project requirements, making it an ideal choice for projects with limited access.

- Q: How does steel formwork contribute to the strength and stability of a concrete structure?

- Steel formwork contributes to the strength and stability of a concrete structure by providing a rigid and durable framework that holds the freshly poured concrete in place until it sets and hardens. The steel formwork acts as a mold, ensuring that the concrete is poured into the desired shape and dimensions, and also prevents any deformation or collapse during the curing process. Its strength and stability ensure that the concrete structure maintains its integrity and can withstand various loads and forces, thereby enhancing its overall strength and durability.

- Q: Can steel formwork be used for both vertical and horizontal concrete structures?

- Indeed, both vertical and horizontal concrete structures can benefit from the utilization of steel formwork. The versatility of steel formwork grants the ability to effortlessly modify and construct diverse shapes and sizes for varying structures. This resource supplies robust reinforcement, stability, and longevity, thus rendering it appropriate for vertical walls and horizontal slabs alike. Moreover, steel formwork boasts exceptional accuracy in dimensions, guaranteeing meticulous concrete placement and alignment. Furthermore, steel formwork's reusability renders it an economically efficient choice for construction endeavors mandating recurrent employment of formwork systems.

- Q: How does steel formwork compare to wooden formwork?

- Due to its numerous advantages, steel formwork is often considered superior to wooden formwork. Firstly, steel formwork is highly durable and can withstand heavy loads and repeated use, unlike wooden formwork which warps, cracks, or splits. As a result, it has a longer lifespan and reduced maintenance costs. Furthermore, steel formwork ensures greater accuracy and precision in construction. Its rigid structure maintains the desired dimensions and shapes, resulting in better-quality finishes. Conversely, wooden formwork can be challenging to align, potentially causing slight variations or imperfections in the final product. In addition, steel formwork offers increased efficiency and productivity. It can be easily assembled, disassembled, and relocated, reducing construction time and labor costs. Moreover, steel formwork requires minimal cleaning and maintenance, eliminating the constant need for repairs or replacements associated with wooden formwork. Moreover, steel formwork is more resistant to moisture and weather conditions. It does not absorb water or warp when exposed to rain or humidity, making it suitable for various climates. Conversely, wooden formwork can degrade when exposed to moisture, potentially compromising the structural integrity of the construction. Although the initial investment in steel formwork may be higher than that of wooden formwork, its long-term benefits outweigh the costs. It provides greater durability, accuracy, efficiency, and resistance to environmental factors, making it the preferred choice in modern construction projects.

- Q: How does steel formwork affect the aesthetics of a building?

- The aesthetics of a building can be significantly impacted by steel formwork in various ways. Firstly, steel formwork allows for the creation of complex and intricate designs, resulting in visually appealing architectural elements. The flexibility and strength of steel enable the construction of unique shapes, curves, and patterns that enhance the overall aesthetics of the building. Moreover, steel formwork gives concrete surfaces a smooth and seamless finish. This contributes to a more refined and polished appearance, especially when compared to other formwork materials like timber or plastic. The absence of visible joints, seams, or imperfections on the concrete surfaces enhances the overall look of the building. Additionally, steel formwork offers the advantage of reusability, leading to cost savings and reduced waste. This economic benefit allows architects and designers to allocate more resources to enhance the building's aesthetics, such as incorporating high-end finishes or unique decorative elements. Furthermore, steel formwork ensures a high level of accuracy and precision during the construction process. This precision guarantees that the final structure is aligned and symmetrical, enhancing the overall visual harmony of the building. Straight lines, sharp corners, and consistent dimensions can be achieved with steel formwork, resulting in a visually pleasing and harmonious architectural design. Lastly, the durability and strength of steel formwork contribute to the long-term aesthetics of the building. Steel formwork can withstand harsh weather conditions, resist corrosion, and maintain its structural integrity over time. This durability ensures that the building's aesthetics remain intact for an extended period, enhancing its overall appeal and value. To conclude, steel formwork has a positive impact on the aesthetics of a building by enabling complex designs, providing a smooth finish, allowing for precision and accuracy, offering cost savings, and ensuring long-lasting visual appeal.

Send your message to us

Steel-Frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords