Climbing-Bracket CB240 & CB210 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

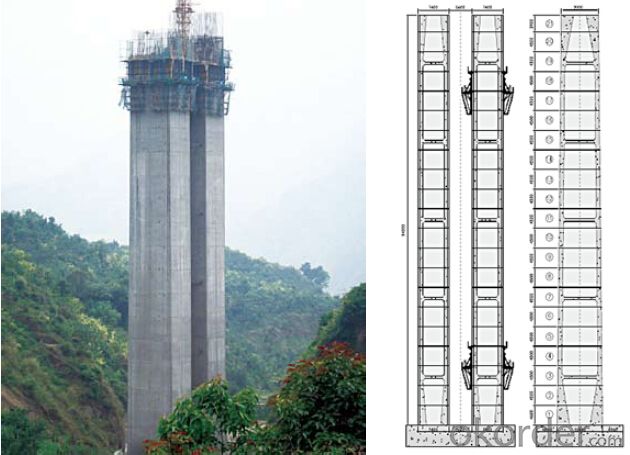

Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the

building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

Characteristics:

◆ High bearing capacity

The high loading capacity of the brackets allow very large scaffold units. This saves the number

anchor points required as well as reducing climbing times.

◆ Simple moving procedure by crane

Through the strong connection of formwork together with the climbing scaffold, both can be moved

as a single climbing unit by crane. Thus valuable time-savings can be achieved.

◆ Fast striking process without a crane

With the retrusive set, large formwork elements can also be retracted quickly and a minimum of

effort.

◆ Safe with work platform

The platforms have assembled firmly with bracket and will be climbing together, without scaffolding

but can work safely in spite of your high location.

- Q: How does steel formwork compare to plastic formwork?

- Steel formwork is generally more durable and long-lasting compared to plastic formwork. It can withstand heavy loads and provides better stability and support during the concrete pouring process. Additionally, steel formwork is reusable and can be easily adjusted and customized according to project requirements. On the other hand, plastic formwork is lighter and easier to handle, making it more suitable for small-scale projects. However, it may not be as sturdy and may require more frequent replacements.

- Q: How does steel formwork ensure accurate concrete dimensions and alignment?

- Steel formwork ensures accurate concrete dimensions and alignment by providing a rigid and stable structure that holds the concrete in place during the pouring and curing process. The steel formwork is designed and fabricated to precise specifications, allowing for precise shaping and positioning of the concrete. The use of steel formwork also reduces the risk of deformation or shifting during the concrete setting, ensuring that the final dimensions and alignment of the concrete structure are maintained.

- Q: Can steel formwork be used for projects with high groundwater levels?

- Indeed, projects confronted with elevated groundwater levels can make use of steel formwork. Steel, being a robust and long-lasting substance, possesses the capability to endure the force exerted by groundwater. By forming a watertight enclosure, it effectively averts the infiltration of water into the construction site. Furthermore, steel formwork can be effortlessly tailored to meet the precise demands of the project, thereby facilitating proficient and successful construction activities amidst high groundwater circumstances.

- Q: How is steel formwork secured to the ground?

- Steel formwork is secured to the ground through several methods to ensure stability and safety during the construction process. One common way to secure steel formwork is by using ground anchors. These anchors are usually made of steel or concrete and are driven into the ground at regular intervals along the perimeter of the formwork. The anchors are then connected to the formwork using steel rods or cables, providing a strong and secure attachment to the ground. Another method of securing steel formwork to the ground is by using steel stakes. These stakes are driven into the ground at regular intervals, and the formwork is then attached to the stakes using various clamps or brackets. This method is commonly used when the ground is not suitable for using ground anchors, such as in rocky or uneven terrains. In addition to ground anchors and stakes, steel formwork can also be secured to the ground by using concrete footing or foundation. This involves pouring concrete footings or foundations at regular intervals along the perimeter of the formwork. The formwork is then attached to the concrete using bolts or other fasteners, providing a solid and stable connection. The method of securing steel formwork to the ground may vary depending on the specific requirements of the construction project and the type of ground conditions. It is essential to follow the manufacturer's instructions and consult with structural engineers to ensure the proper installation and secure attachment of the formwork to the ground.

- Q: Can steel formwork be used in coastal or marine construction projects?

- Yes, steel formwork can be used in coastal or marine construction projects. Steel formwork is known for its durability and strength, making it a suitable choice for projects in harsh environments such as coastal or marine areas. Its resistance to corrosion allows it to withstand the corrosive effects of saltwater and other coastal elements. Additionally, steel formwork can be easily reused and recycled, making it a cost-effective and sustainable option for coastal or marine construction projects.

- Q: How does steel formwork affect the overall vibration resistance of the structure?

- Steel formwork can significantly enhance the overall vibration resistance of a structure. Due to its strong and rigid nature, steel formwork provides excellent support and stability during the construction process, preventing any excessive movement or vibration. This helps in reducing the risk of structural damage or failure caused by vibration, ensuring the durability and safety of the building in the long run.

- Q: What are the common accessories used with steel formwork?

- Steel formwork commonly utilizes various accessories such as form ties, wedges, form release agents, formwork clamps, and form liners. Form ties play a crucial role in securing the formwork and maintaining its position throughout the concrete pouring and curing stages. They are typically constructed from steel and are available in different lengths and designs to accommodate diverse formwork needs. Wedges, typically composed of steel or plastic, are essential in conjunction with form ties to firmly secure the formwork. They are inserted into the form tie to provide a tight grip and ensure stability. Form release agents are applied to the formwork surface to prevent concrete from adhering to it. By creating a barrier between the concrete and formwork, they facilitate easy removal of the formwork after the concrete has cured. Formwork clamps, made of steel and offered in various sizes and designs, are used to hold the formwork panels together and maintain proper alignment during concrete pouring. Form liners, typically constructed from plastic or elastomeric materials, are attached to the formwork prior to concrete pouring. They enable the creation of decorative patterns or textures on the concrete surface. Upon the concrete's curing, the form liners are removed, leaving behind the desired appearance. These accessories are frequently employed in conjunction with steel formwork systems to optimize efficiency and effectiveness during the construction process, resulting in high-quality concrete structures.

- Q: What are the main components of steel formwork?

- The main components of steel formwork are panels, stiffeners, and connecting brackets. Steel formwork panels are typically made of high-quality steel sheets that are rigid and durable. These panels come in various sizes and shapes, such as rectangular, square, or circular, depending on the required shape of the concrete structure. They are designed to withstand the pressure exerted by the concrete during pouring and curing. Stiffeners are used to reinforce the steel formwork panels and enhance their load-bearing capacity. They are usually welded or bolted onto the panels to provide additional strength and stability. Stiffeners are particularly important in large-scale projects or when dealing with heavy concrete loads. Connecting brackets play a vital role in assembling the steel formwork system. They are used to connect the formwork panels together and ensure proper alignment and stability. These brackets are typically made of steel and are designed to securely hold the formwork panels in place. They are easy to install and remove, allowing for efficient and convenient formwork assembly. Overall, steel formwork offers numerous advantages such as high strength, durability, and reusability. Its main components, panels, stiffeners, and connecting brackets, work together to create a robust and reliable system that can withstand the pressure of concrete pouring and provide a smooth and accurate surface finish.

- Q: How does steel formwork affect the schedule of a construction project?

- Steel formwork can have a significant impact on the schedule of a construction project. One of the main advantages of using steel formwork is its durability and reusability. Unlike traditional wood formwork, steel formwork can be used multiple times, resulting in faster construction cycles. This means that the formwork can be easily dismantled and reassembled at different parts of the project, allowing for concurrent construction activities and ultimately reducing the overall construction time. Additionally, steel formwork provides better dimensional control and accuracy, ensuring that the concrete structures are built according to the specified designs. This reduces the need for rework or corrections, which can further save time and resources. Furthermore, steel formwork is known for its strength and stability, which enables it to withstand the pressure exerted by the concrete during pouring and curing. This allows for faster pouring and curing times, as well as the ability to achieve higher concrete strengths in a shorter period. Moreover, steel formwork systems often come with integrated features such as adjustable props and support systems, which provide flexibility and efficiency during construction. These features allow for quick adjustments and modifications, resulting in faster construction progress. However, it is important to note that the installation and dismantling of steel formwork may require specialized labor and equipment, which can add some time to the project schedule. Additionally, the initial cost of steel formwork may be higher compared to traditional formwork materials. However, the long-term benefits and time savings provided by steel formwork can outweigh these initial costs. In conclusion, steel formwork can significantly affect the schedule of a construction project by reducing construction cycles, improving dimensional control, enabling faster pouring and curing times, and providing flexibility and efficiency. While it may require some additional time for installation and higher initial costs, the overall time savings and benefits make steel formwork a valuable choice for construction projects.

- Q: Can steel formwork be used for concrete culverts?

- Certainly, concrete culverts can indeed utilize steel formwork. Notably, steel formwork exhibits exceptional strength and durability, rendering it capable of withstanding the immense pressures and weight exerted by the poured concrete. Moreover, this material furnishes a sturdy framework that effectively shapes and supports the concrete until its solidification and hardening. Furthermore, the assembly and disassembly of steel formwork are effortlessly executed, thereby ensuring its reusability and cost-effectiveness. Given its robustness, adaptability, and extensive lifespan, steel formwork is extensively employed in diverse construction undertakings, including the fabrication of concrete culverts.

Send your message to us

Climbing-Bracket CB240 & CB210 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches