Steel-Frame Formwork System Link Part

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

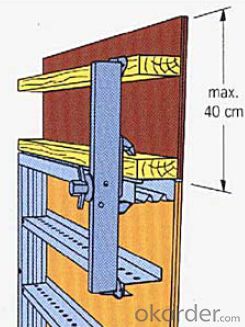

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Are there any specific considerations for using steel formwork in earthquake-prone areas?

- Yes, there are specific considerations for using steel formwork in earthquake-prone areas. Steel formwork offers several advantages such as strength, durability, and reusability. However, it is crucial to ensure that the steel formwork is designed and constructed to withstand the seismic forces generated during an earthquake. The formwork system should comply with local building codes and regulations related to seismic design. It is also important to consider factors like steel quality, connection details, bracing systems, and anchorage methods to enhance the formwork's resistance to seismic loads. Additionally, regular inspections and maintenance of the steel formwork are necessary to ensure its integrity and effectiveness in earthquake-prone areas.

- Q: The wooden plank road construction, the steel structure and the template pavement, the railing installation all construction labor cost to want how many money? Or how much a square?

- Under normal circumstances, in accordance with the plant area of about 30--60 per square meter. For reference only.

- Q: How does steel formwork prevent concrete mixture separation during pouring?

- Steel formwork is used in construction projects to provide a temporary structure that holds the concrete in place until it sets and hardens. One of the key benefits of using steel formwork is that it prevents the concrete mixture from separating during the pouring process. The steel formwork is carefully designed and constructed to create a tight enclosure for the concrete, ensuring that it remains in its desired shape and consistency. It is made up of steel panels and frames that are securely fastened together to create a rigid structure. When the concrete mixture is poured into the steel formwork, it is held in place by the walls of the formwork itself. The steel panels and frames provide a smooth and even surface for the concrete to be poured onto, preventing any separation or segregation of the mixture. Furthermore, the steel formwork is designed with properly aligned joints and connections, which further helps in preventing any leakage or seepage of the concrete mixture. This ensures that the concrete remains intact and does not separate into its constituent materials such as aggregates, cement, and water. Additionally, the steel formwork is capable of withstanding the pressure exerted by the weight of the concrete. This prevents any deformation or movement of the formwork during the pouring process, which could potentially cause the concrete to separate or shift. Overall, the use of steel formwork provides a strong and stable structure that prevents the concrete mixture from separating during pouring. It ensures that the concrete remains in its desired form and consistency, resulting in a high-quality and durable finished product.

- Q: Can steel formwork be used for decorative concrete finishes?

- Yes, steel formwork can be used for decorative concrete finishes. It provides sturdy support and precise shaping, allowing for intricate designs and smooth finishes in decorative concrete applications.

- Q: What are the common safety guidelines when working with steel formwork in hazardous areas?

- When working with steel formwork in hazardous areas, it is important to follow some common safety guidelines. These include wearing appropriate personal protective equipment (PPE) such as safety goggles, gloves, and steel-toed boots to protect against potential hazards. Additionally, workers should ensure that the steel formwork is properly installed and secured to prevent any accidents or collapses. It is also essential to be aware of the weight and load capacity of the formwork to avoid overloading and potential structural failures. Regular inspections and maintenance of the formwork are necessary to identify any defects or weaknesses that could compromise safety. Lastly, workers should be trained on emergency procedures and know the location of emergency exits and evacuation routes in case of any unforeseen incidents.

- Q: Can steel formwork be used for both reinforced and non-reinforced concrete structures?

- Yes, steel formwork can be used for both reinforced and non-reinforced concrete structures. Steel formwork provides a strong and durable framework for concrete pouring and can be easily customized to accommodate different structural requirements, whether it involves reinforcing steel bars or not.

- Q: Can steel formwork be used for tall structures?

- Yes, steel formwork can be used for tall structures. Steel formwork is a versatile and durable option for constructing tall buildings. It offers significant advantages such as high strength, rigidity, and stability, making it an ideal choice for tall structures. Steel formwork can withstand the high pressures exerted by fresh concrete and provide a smooth and even surface finish. It is also reusable, reducing construction costs and environmental impact. Additionally, steel formwork allows for precise customization and can be easily adjusted to accommodate various architectural designs and structural requirements. Overall, steel formwork is a reliable and efficient solution for constructing tall structures.

- Q: How does steel formwork contribute to the overall sustainability credentials of the project?

- Steel formwork contributes to the overall sustainability credentials of a project in several ways. Firstly, steel is a highly durable material, which means that it can be reused multiple times, reducing the need for new materials and minimizing waste. Additionally, steel formwork allows for greater flexibility in design, enabling efficient use of materials and reducing construction time and costs. Moreover, steel is a recyclable material, so at the end of its life cycle, it can be recycled and used in other projects, further reducing environmental impact. Overall, steel formwork helps to promote sustainability by promoting resource efficiency, reducing waste, and minimizing the carbon footprint of construction projects.

- Q: Can steel formwork be used for both flat and sloped surfaces?

- Indeed, flat and sloped surfaces can both accommodate the utilization of steel formwork. When it comes to construction endeavors, steel formwork proves to be a versatile and enduring option that readily adapts to the formation of structures with diverse inclinations. The malleability of steel enables it to be manipulated and contoured to the desired angle, rendering it suitable for the creation of formwork for surfaces with slopes. Furthermore, steel formwork offers exceptional support and stability, guaranteeing precise and uniform pouring of concrete on both flat and sloped surfaces. Its robustness and rigidity ensure the construction of formwork systems capable of enduring the pressures exerted by the concrete throughout the casting process, irrespective of the surface's gradient.

- Q: Can steel formwork be used in architectural concrete projects?

- Architectural concrete projects can indeed utilize steel formwork. Due to its durability, strength, and versatility, steel formwork is frequently chosen for various construction endeavors, including architectural concrete. By providing exceptional support and stability to the concrete structure, steel formwork ensures that the desired shape and form are maintained throughout the pouring and curing process. Additionally, steel formwork's resistance to warping or bending under the weight and pressure of the concrete is essential for achieving accurate and precise architectural designs. Moreover, steel formwork facilitates easy assembly and dismantling, making it a cost-effective option for architectural concrete projects. Overall, architects and builders seeking to create intricate and aesthetically pleasing concrete structures can rely on the reliability and efficiency of steel formwork.

Send your message to us

Steel-Frame Formwork System Link Part

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords