Steel-Frame Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

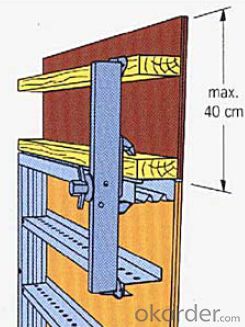

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the standard sizes of steel formwork panels?

- The standard sizes of steel formwork panels can vary depending on the specific requirements of the construction project and the manufacturer. However, there are some commonly used standard sizes in the industry. Typically, steel formwork panels come in rectangular shapes with dimensions ranging from 1.2 meters to 2.4 meters in width and 1.8 meters to 3.6 meters in height. These standard sizes are designed to accommodate various construction needs and provide flexibility in forming structures such as walls, columns, slabs, and beams. The thickness of steel formwork panels can also vary, usually ranging from 12mm to 20mm. Thicker panels may be used for heavy-duty applications or to provide additional strength and durability to withstand the pressure exerted by concrete during pouring. It is worth noting that while these are common standard sizes, custom sizes can also be manufactured to meet specific project requirements. Additionally, some manufacturers may offer modular formwork systems that allow for easy assembly and disassembly by combining standard-sized panels in different configurations. Ultimately, the choice of steel formwork panel size depends on factors such as the size and complexity of the structure being formed, the load-bearing capacity required, and the ease of transportation and handling on the construction site.

- Q: How does steel formwork contribute to the overall durability of the structure?

- Steel formwork contributes to the overall durability of a structure in several ways. Firstly, steel is a strong and rigid material that provides excellent support and stability during the concrete pouring process. This ensures that the structure maintains its shape and form accurately, minimizing any potential deformations or cracks. Additionally, steel formwork is highly resistant to corrosion, which helps protect the concrete from moisture and other environmental factors that can weaken its integrity over time. Furthermore, steel formwork can be easily reused multiple times, reducing material waste and increasing cost-effectiveness. Overall, the use of steel formwork enhances the structural strength and longevity of the building, ensuring its durability for years to come.

- Q: How does steel formwork affect the overall thermal performance of the structure?

- Steel formwork can have a significant impact on the overall thermal performance of a structure. The main factor that influences this is the thermal conductivity of steel. Steel has a high thermal conductivity, meaning it can easily transfer heat from one side to the other. When steel formwork is used in the construction of a building, it acts as a thermal bridge between the interior and exterior of the structure. This can result in heat transfer across the steel formwork, leading to increased heat loss or gain depending on the external temperature. In colder climates, steel formwork can contribute to higher heat loss, resulting in increased energy consumption for heating. Similarly, in warmer climates, steel formwork can allow heat to transfer into the building, leading to increased cooling requirements. To mitigate this thermal bridging effect, various measures can be taken. One approach is to use thermal breaks, which are insulating materials placed between the steel formwork and the rest of the structure. These breaks help reduce the heat transfer through the steel, improving the overall thermal performance. Another approach is to use alternative formwork materials with lower thermal conductivity, such as insulated concrete forms (ICFs) or wood. It is important to consider the thermal performance of steel formwork during the design and construction phases to ensure energy efficiency and occupant comfort. By implementing proper insulation and thermal breaks, the negative impact of steel formwork on the overall thermal performance of the structure can be minimized.

- Q: How does steel formwork affect the overall thermal insulation of a structure?

- The thermal insulation of a structure is not directly influenced by steel formwork, as its primary function is to shape and support concrete during construction. Steel formwork is primarily used for providing structural stability and shaping concrete elements like walls, slabs, and columns. Other factors, such as the type and thickness of insulation materials, the design of the building envelope, and the presence of thermal bridges, primarily determine the overall thermal insulation of a structure. Insulation materials like foam boards, fiberglass, or mineral wool are typically installed within walls, floors, and roofs to limit heat transfer through conduction, convection, and radiation. Although steel formwork itself does not significantly contribute to thermal insulation, it can indirectly impact the insulation of a structure through its influence on the construction process. For example, if the steel formwork is not properly sealed or installed, it can create gaps or voids in the concrete, allowing heat to escape or enter the building. Moreover, inaccurate alignment of the formwork can affect the placement of insulation materials, leading to thermal bridging and reduced overall insulation effectiveness. Regardless of the formwork type used, it is crucial to implement proper insulation measures during the construction process. This involves ensuring correct installation of insulation materials without any gaps or thermal bridges, as well as proper sealing of the formwork to prevent air leakage. By addressing these aspects, the thermal insulation of the structure can be effectively maintained, irrespective of the presence of steel formwork.

- Q: Can steel formwork be used for precast concrete slabs with openings?

- Yes, steel formwork can be used for precast concrete slabs with openings. Steel formwork is known for its strength and durability, making it suitable for creating complex and intricate designs, including slabs with openings. Steel formwork allows for precise and accurate construction, ensuring that the openings are formed with the desired dimensions and shape. The steel formwork can be easily adjusted and modified to accommodate different sizes and shapes of openings, providing flexibility in design. Additionally, steel formwork can be reused multiple times, making it a cost-effective choice for precast concrete slabs with openings. However, it is important to ensure that the steel formwork is properly engineered and designed to withstand the weight and forces exerted by the concrete and the openings.

- Q: How does steel formwork affect the overall aesthetics of a concrete structure?

- The overall aesthetics of a concrete structure can be significantly influenced by the use of steel formwork. Utilizing steel as a material for formwork offers numerous advantages that directly contribute to enhancing the visual appeal of the final concrete product. To begin with, the concrete surface can achieve a smooth and uniform finish through the use of steel formwork. The rigid nature of steel ensures that there are no imperfections or irregularities present on the formwork, resulting in a flawless and visually pleasing concrete structure. This is particularly important for architectural elements that aim for a sleek and polished appearance. Additionally, steel formwork allows for greater flexibility in design. By utilizing steel, it becomes possible to create complex and intricate shapes, curves, and patterns that can transform a concrete structure into a piece of art. The malleability of steel enables architects and designers to push the boundaries of creativity, resulting in visually stunning concrete structures that stand out. Moreover, steel formwork offers excellent dimensional stability. It can withstand the pressure exerted by the fresh concrete, ensuring that the formwork maintains its shape and integrity throughout the pouring and curing process. This stability prevents any deformations or distortions in the concrete, resulting in a consistent and visually appealing appearance. Furthermore, steel formwork provides superior strength and durability. This allows for the construction of larger and taller concrete structures, which can be visually impressive and impactful. The robustness of steel formwork ensures that the concrete structure remains structurally sound and visually appealing for an extended period of time. In conclusion, steel formwork plays a crucial role in enhancing the aesthetics of a concrete structure. Its ability to provide a smooth finish, offer design flexibility, maintain dimensional stability, and provide strength contributes to the creation of visually pleasing and architecturally impressive buildings. Whether it is a high-rise tower, an intricate bridge, or an iconic landmark, steel formwork helps elevate the overall aesthetics and visual impact of the concrete structure.

- Q: How does steel formwork contribute to the overall stability of a structure?

- Steel formwork contributes to the overall stability of a structure by providing a robust and rigid framework for concrete placement. Its strength and durability prevent deformation or displacement during the pouring and curing process, ensuring the concrete sets in the desired shape and position. This stability allows for the proper alignment and distribution of loads, enhancing the structural integrity of the building and reducing the risk of any potential structural failures.

- Q: Can steel formwork be used in areas with high seismic activities?

- Indeed, areas with high seismic activities can utilize steel formwork. Renowned for its strength and durability, steel proves to be an appropriate construction material in earthquake-prone regions. The resilience of steel formwork against lateral forces and seismic vibrations guarantees the structure's safety and stability. Moreover, steel formwork offers exceptional flexibility, allowing for tailored construction solutions to accommodate diverse shapes and sizes in high seismic areas. Ultimately, steel formwork emerges as a dependable and efficient choice for construction endeavors in regions characterized by high seismic activities.

- Q: Can steel formwork be used for precast concrete elements?

- Yes, steel formwork can be used for precast concrete elements. Steel formwork is a popular choice for precast concrete fabrication due to its durability and reusability. It provides a strong and rigid structure that can withstand the pressure of wet concrete during casting and the weight of the hardened concrete after curing. Steel formwork also offers a smooth and consistent finish to the precast elements, ensuring high-quality and precise results. Additionally, steel formwork can be easily assembled and disassembled, allowing for efficient production and easy transportation of precast elements.

- Q: How does steel formwork affect the overall durability of a structure?

- Steel formwork can significantly enhance the durability of a structure. Due to its robust nature, steel formwork provides excellent support and stability during the construction process. This ensures that the structure maintains its shape and integrity, even when subjected to heavy loads and external forces. Additionally, steel formwork is highly resistant to wear and corrosion, prolonging the lifespan of the structure. Its durability also allows for multiple reuses, reducing construction costs and environmental impact. Overall, the use of steel formwork contributes to the long-term durability and strength of a structure.

Send your message to us

Steel-Frame Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords