Steel-frame Formwork and Scaffolding System SF-140

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

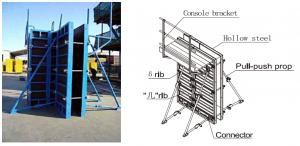

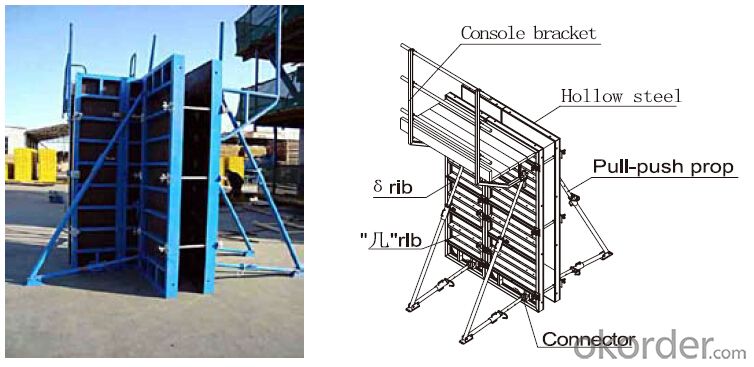

1. Structure of Steel-frame Formwork and Scaffolding System SF-140

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel-frame Formwork and Scaffolding System SF-140

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

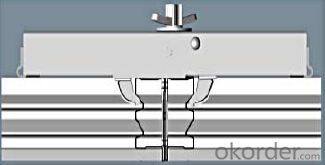

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

3. Steel-frame Formwork and Scaffolding System SF-140 Images

4. Steel-frame Formwork and Scaffolding System SF-140 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel-frame Formwork and Scaffolding System SF-140

1) What can we do for you?

.We can ensure the quality of the Steel-frame Formwork and Scaffolding System SF-140 and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel-frame Formwork and Scaffolding System SF-140, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork SF140 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel-frame Formwork and Scaffolding System SF-140, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel formwork be used for architectural concrete elements?

- Yes, steel formwork can be used for architectural concrete elements. Steel formwork is a type of temporary mold or framework that is used to hold and shape concrete until it hardens and gains sufficient strength to support itself. It is commonly used in construction for various concrete structures, including architectural elements such as columns, beams, walls, slabs, and even decorative elements. One of the main advantages of using steel formwork for architectural concrete elements is its strength and durability. Steel is a strong material that can withstand the pressure exerted by fresh concrete, ensuring that the formwork remains intact during the pouring and curing process. This allows for the creation of complex shapes and intricate designs that are often required in architectural concrete elements. Additionally, steel formwork can be easily assembled and disassembled, making it a flexible and reusable option. The modular nature of steel formwork allows for quick and efficient construction, saving both time and costs. It can be adjusted and customized to meet specific design requirements, providing architects and engineers with greater design freedom. Furthermore, steel formwork provides a smooth and uniform surface finish to the concrete, which is important for architectural elements where aesthetics play a significant role. The use of steel formwork ensures that the final concrete product has a high-quality finish, enhancing its visual appeal. However, it is important to note that steel formwork may not be suitable for all architectural concrete elements. Factors such as project budget, timeline, complexity, and design requirements should be considered when selecting the appropriate formwork system. In some cases, alternative formwork materials such as timber, plywood, or plastic may be more suitable depending on the specific project needs. In conclusion, steel formwork can be successfully used for architectural concrete elements, offering strength, durability, flexibility, and a high-quality finish. It is a widely accepted and commonly used formwork material in the construction industry, providing architects and engineers with the means to create visually appealing and structurally sound concrete structures.

- Q: How does steel formwork handle concrete bleeding and segregation?

- Steel formwork is known for its ability to effectively handle concrete bleeding and segregation. Bleeding refers to the process where water in the concrete mixture rises to the surface, leaving behind a layer of water on top. Segregation, on the other hand, occurs when the solid particles in the concrete mixture separate from the water, resulting in an uneven distribution. Steel formwork helps to minimize bleeding and segregation by providing a rigid structure that holds the concrete in place during the pouring and curing process. The tight joints and sturdy construction of steel formwork prevent the concrete from leaking or seeping out, thus reducing bleeding. Additionally, steel formwork allows for better control over the concrete placement and compaction process. The smooth and non-absorbent surface of steel formwork helps in achieving a uniform distribution of the concrete mixture, reducing the risk of segregation. The use of steel formwork also allows for proper vibration and consolidation of the concrete, helping to eliminate any potential voids or air pockets that may contribute to segregation. Furthermore, steel formwork provides stability during the curing process, ensuring that the concrete remains in its desired position without any significant movement. This stability helps to prevent any potential disturbances that could lead to bleeding or segregation. In summary, steel formwork is highly effective in handling concrete bleeding and segregation due to its rigid structure, tight joints, smooth surface, and stability. Its use promotes a more uniform and consolidated concrete placement, resulting in a higher quality finished product.

- Q: Can steel formwork be used for energy-efficient concrete buildings?

- Yes, steel formwork can be used for energy-efficient concrete buildings. Steel formwork is known for its strength, durability, and versatility, making it a suitable choice for constructing energy-efficient structures. Steel formwork allows for precise design and construction, which is crucial in achieving energy efficiency in buildings. It can be customized to create complex shapes and intricate designs, enabling architects and engineers to incorporate energy-efficient features such as insulated walls, solar shading devices, and efficient HVAC systems. Moreover, steel formwork provides excellent thermal conductivity, which is beneficial for maintaining consistent indoor temperatures and reducing energy consumption. By using steel formwork, the concrete walls and floors can be designed with insulation materials that provide high thermal resistance, minimizing heat transfer through the building envelope. This helps to reduce the energy required for heating and cooling, resulting in improved energy efficiency. Additionally, steel formwork can be easily reused, reducing construction waste and promoting sustainability. It can be dismantled and reassembled for multiple projects, making it a cost-effective and environmentally friendly option. By choosing steel formwork for energy-efficient concrete buildings, not only can energy consumption be minimized, but also the overall environmental impact can be reduced. In conclusion, steel formwork can be used effectively in the construction of energy-efficient concrete buildings. Its strength, durability, versatility, and thermal conductivity make it a suitable choice for incorporating energy-efficient features into the building design. Furthermore, its reusability promotes sustainability, making steel formwork a viable option for creating energy-efficient structures.

- Q: How does steel formwork affect the overall project budget?

- The overall project budget can be significantly impacted by steel formwork. Although steel formwork may be more expensive initially compared to other types of formwork like timber or plywood, it provides several advantages that can ultimately result in cost savings. Durability is one of the main benefits of steel formwork. Steel is a strong and long-lasting material that can withstand multiple uses without wearing down. This means that steel formwork can be reused for many projects, reducing the need for frequent replacements and lowering long-term costs. In addition, steel formwork allows for faster construction times. Its strength and stability enable contractors to pour concrete more quickly, reducing labor costs and streamlining the construction process. Moreover, steel formwork can be easily put together and taken apart, resulting in shorter intervals between projects. Steel formwork also ensures high-quality concrete structures with precision and consistency. This can minimize the need for rework and corrections, thereby reducing costs associated with fixing errors or imperfections. Furthermore, steel formwork offers design flexibility. It can be customized to fit different shapes and sizes, providing greater architectural freedom and creativity. This versatility can lead to cost savings by eliminating the need for expensive and complex modifications to the formwork system. Lastly, steel formwork is resistant to moisture and weather conditions. Unlike timber or plywood, steel does not warp or deteriorate when exposed to moisture, which can save costs by avoiding replacements or repairs due to water damage. To summarize, although steel formwork may be initially more expensive, its durability, reusability, speed, precision, flexibility, and resistance to environmental factors can result in overall cost savings throughout the project. By considering the long-term benefits and efficiencies offered by steel formwork, project budgets can be effectively managed and optimized.

- Q: How does steel formwork handle concrete pumping and placing?

- Steel formwork is well-suited to handle concrete pumping and placing due to its strength and durability. It provides a rigid structure that can withstand the pressure and force exerted during the pumping process without deforming or collapsing. Additionally, steel formwork offers a smooth surface that allows for easy and efficient placement of concrete, ensuring proper consolidation and adherence to the formwork. Its robust nature also allows for multiple uses and easy cleaning, making it a preferred choice for concrete pumping and placing.

- Q: What is steel formwork?

- Steel formwork is a type of temporary mold or structure that is used in construction to shape and support concrete until it sets and hardens. It is made of steel sheets or plates that are welded together to create a framework. This framework is then used to hold the concrete in place while it is poured and compacted. Steel formwork is known for its durability, strength, and ability to withstand the pressure exerted by wet concrete. It is commonly used in large-scale construction projects, such as high-rise buildings, bridges, and tunnels, where the concrete needs to be shaped into complex and precise forms. Steel formwork can be easily assembled and disassembled, making it reusable and cost-effective. It also provides a smooth and uniform finish to the concrete surface, resulting in a high-quality end product. Overall, steel formwork is an essential tool in modern construction that helps in the efficient and effective construction of concrete structures.

- Q: How does steel formwork affect the overall moisture resistance of the structure?

- Steel formwork can have both positive and negative effects on the overall moisture resistance of a structure. On one hand, steel formwork provides a rigid and impermeable barrier to prevent water penetration into the concrete during the construction phase. This can be particularly beneficial in areas with high moisture content or where water infiltration could compromise the integrity of the structure. However, steel formwork may also contribute to the overall moisture resistance challenges. Unlike other formwork materials such as wood or plastic, steel is prone to corrosion when exposed to moisture over extended periods. If the steel formwork is not properly protected or maintained, it can develop rust, which can weaken its structural integrity and potentially compromise the overall moisture resistance of the structure. Additionally, steel formwork can create a thermal bridge within the structure. Steel has a high thermal conductivity, meaning that it can easily transfer heat or cold from one side to another. This can lead to condensation issues and potential moisture problems if proper insulation or vapor barrier measures are not taken. To mitigate these potential drawbacks, it is crucial to apply appropriate anti-corrosion coatings and ensure proper maintenance of the steel formwork. Additionally, adequate insulation and vapor barrier systems should be installed to minimize the impact of thermal bridging and prevent condensation issues. Overall, while steel formwork can provide initial protection against moisture during construction, it is important to address its vulnerabilities to corrosion and thermal bridging to maintain the overall moisture resistance of the structure in the long term.

- Q: What are the different types of surface treatments available for steel formwork?

- Steel formwork offers a variety of surface treatments, each with its own unique benefits and characteristics. One option is galvanization, which involves applying a layer of zinc to the steel. This treatment protects against corrosion, extends durability, and provides a smoother surface finish. Another choice is powder coating, where a dry powder is applied and heated to create a protective layer. This treatment offers excellent resistance to corrosion, impacts, and chemicals, and comes in a wide range of colors. Painting is a common method where a layer of paint is applied for both aesthetics and protection against corrosion and environmental factors. Epoxy coating is another option, involving a layer of epoxy resin that provides resistance to corrosion, chemicals, and abrasion. It also offers easy cleaning and maintenance with its smooth finish. Shot blasting is a process of propelling steel shots onto the surface to remove rust, scale, or contaminants, resulting in a clean and roughened finish. This treatment also improves adhesion for subsequent surface treatments. Although typically used for aluminum formwork, anodizing can also be applied to steel. This treatment creates an oxide layer that enhances corrosion resistance and improves appearance. Overall, the choice of surface treatment for steel formwork depends on factors such as corrosion resistance, aesthetics, durability, and environmental conditions. It is important to consider these factors before selecting the most suitable treatment.

- Q: Is steel formwork suitable for projects with tight deadlines?

- Indeed, projects with tight deadlines can benefit from the use of steel formwork. Its exceptional durability and strength enable it to withstand high pressure and repetitive use. Consequently, it can be reused multiple times without compromising its structural integrity, resulting in faster construction. Furthermore, the assembly and disassembly of steel formwork are effortless, facilitating quick and efficient installation and removal. Its adaptability and versatility make it a suitable choice for construction projects of any scale or complexity. Consequently, incorporating steel formwork into projects with tight deadlines can accelerate the construction process and ensure timely completion.

- Q: How does steel formwork affect the overall waterproofing of a building?

- The main purpose of steel formwork is to provide stability and shape to wet concrete during the construction process. It does not directly affect the overall waterproofing of a building. Waterproofing is typically achieved through the use of waterproof membranes, sealants, or coatings applied to the external surfaces of the structure. Proper installation and sealing of the formwork joints are important to prevent water leakage during the concrete pouring process. Any gaps or cracks in the formwork can allow water to seep into the structure, potentially compromising the waterproofing system. Additionally, the choice of formwork material indirectly influences the overall waterproofing of a building. Steel formwork, being durable and robust, can withstand the pressure of wet concrete without deforming or leaking. This ensures that the concrete is shaped and compacted correctly, resulting in a more solid and stable structure. A well-constructed concrete framework indirectly contributes to the building's waterproofing capabilities by enhancing its integrity and longevity. In conclusion, while steel formwork does not directly impact the overall waterproofing of a building, it is crucial for maintaining the structural integrity of the concrete during construction. Proper installation and sealing of formwork joints are necessary to prevent water leakage. Ultimately, the choice and correct application of appropriate waterproofing materials determine the building's overall waterproofing performance.

Send your message to us

Steel-frame Formwork and Scaffolding System SF-140

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords