Steel-frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

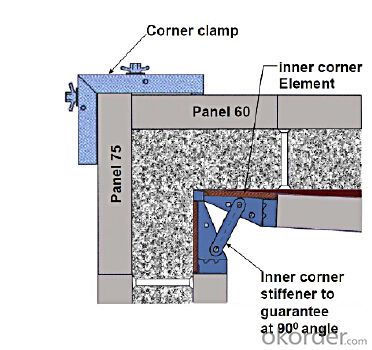

◆ Neat joint and fast assembling with aligning panel clamp.

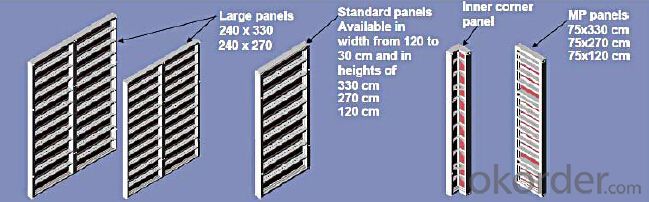

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

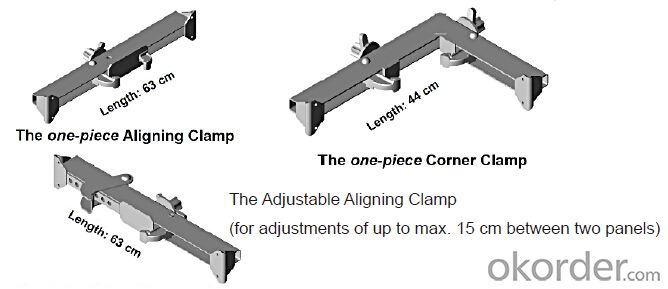

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the different types of form ties used in steel formwork?

- There are several types of form ties used in steel formwork, including wedge bolts, loop ties, taper ties, and she-bolts.

- Q: How does steel formwork handle concrete vibration during pouring?

- Steel formwork, widely used in concrete pouring processes, is a versatile and durable construction material. It possesses several advantages when it comes to managing concrete vibration during pouring. To begin with, the high strength and rigidity of steel formwork enable it to withstand the intense vibrations caused by the pouring of concrete. Its robustness ensures stability and prevents potential deformation or collapse that weaker materials might experience. Moreover, steel formwork is designed with interlocking systems and tight joints, minimizing the possibility of concrete leakage. This containment of the concrete within the formwork streamlines the pouring process, reducing the need for excessive cleanup or rework. Furthermore, steel formwork efficiently transmits vibrations throughout its structure. This transmission aids in eliminating air bubbles and voids, resulting in a more uniform and compact final product. Effective vibration transmission enhances the overall strength and durability of the structure. Lastly, steel formwork is highly reusable and easily disassembled, making it ideal for multiple projects. This cost-effective and sustainable quality reduces the requirement for constant replacement of formwork materials. The ability to reuse steel formwork also ensures its consistent effectiveness in handling concrete vibration over time. In conclusion, steel formwork is a dependable and efficient material for managing concrete vibration during pouring. Its strength, stability, and vibration transmission capabilities make it a preferred choice in construction projects involving concrete pouring and compaction.

- Q: How does steel formwork handle different concrete expansion properties?

- Steel formwork is a highly versatile and reliable choice when it comes to handling different concrete expansion properties. The primary reason for this is that steel has excellent tensile strength and durability, allowing it to withstand the forces exerted by expanding concrete. Concrete expands and contracts due to temperature changes, moisture absorption, and chemical reactions. Steel formwork is designed to accommodate these expansion properties through its flexible nature. The steel panels used in formwork systems can be easily adjusted, allowing for expansion and contraction without causing damage to the structure. In addition to its flexibility, steel formwork also provides stability to the concrete during the curing process. It prevents the concrete from sagging or deforming under its own weight, ensuring a uniform and even surface. This stability is crucial in preventing cracks or other structural issues caused by uneven expansion. Moreover, steel formwork is known for its heat conductivity. This property helps in dissipating heat generated during the hydration process of concrete, reducing the risk of thermal cracks. By efficiently managing the heat generated, steel formwork minimizes the impact of temperature fluctuations on the concrete's expansion properties. Furthermore, steel formwork can be easily reinforced with additional supports or braces, if needed, to further enhance its ability to handle different concrete expansion properties. These reinforcements can be strategically placed to provide additional strength and stability, allowing the formwork to accommodate any expansion or contraction without compromising the integrity of the structure. Overall, steel formwork is a reliable and effective choice for handling different concrete expansion properties. Its flexibility, stability, and ability to dissipate heat make it an ideal material for accommodating the natural movements of concrete, ensuring a durable and long-lasting structure.

- Q: Can steel formwork be used in educational or institutional construction projects?

- Yes, steel formwork can be used in educational or institutional construction projects. Steel formwork is commonly used in various construction projects, including those in the educational and institutional sectors. It provides a durable and versatile solution for casting concrete structures, ensuring the strength and stability required for these types of projects. Additionally, steel formwork allows for efficient construction processes, reducing the overall project duration and costs.

- Q: How does steel formwork handle different concrete surface preparation techniques?

- Steel formwork is highly versatile and can handle various concrete surface preparation techniques with ease. Whether the concrete surface needs to be smooth, textured, or have specific patterns, steel formwork can accommodate all these requirements. It provides a strong and stable framework to hold the concrete in place during pouring and curing, ensuring that the desired surface finish is achieved. Additionally, steel formwork allows for easy demolding and reusability, making it a preferred choice for construction projects requiring different concrete surface preparation techniques.

- Q: Is steel formwork more durable than other types of formwork?

- Compared to other types of formwork, steel formwork is undoubtedly more durable. This is due to the fact that steel is a robust and sturdy material capable of withstanding heavy loads and high pressures. Its resistance to wear and tear makes it ideal for construction projects that involve repetitive use of formwork. Unlike wood or plastic, steel formwork does not easily warp, crack, or deteriorate over time. This exceptional durability allows for multiple concrete pours without the need for frequent replacements, resulting in long-term cost savings. Furthermore, steel formwork's fire-resistant properties further enhance its durability and safety features. In conclusion, steel formwork is a reliable choice for construction projects, offering superior durability when compared to other types of formwork.

- Q: How does steel formwork affect the overall construction cost estimate?

- Steel formwork can have both positive and negative effects on the overall construction cost estimate. On the positive side, steel formwork is known for its durability and reusability, which can lead to cost savings in the long run. Unlike traditional timber formwork, steel formwork can withstand multiple uses, reducing the need for constant replacement and lowering material costs over time. Additionally, steel formwork provides better dimensional accuracy and stability, resulting in faster construction processes. This can lead to shorter project durations and reduced labor costs, ultimately impacting the overall construction cost estimate positively. However, it is worth noting that steel formwork generally has a higher upfront cost compared to timber formwork. The initial investment required for steel formwork can be significant, especially for large-scale projects. This cost can include the purchase or rental of the steel formwork system, transportation, and installation expenses. Furthermore, steel formwork may require skilled labor for its assembly and dismantling, which can increase labor costs. It is crucial to have experienced workers who are familiar with steel formwork systems, as any mistakes during the construction process can result in additional expenses and delays. Overall, the impact of steel formwork on the construction cost estimate depends on various factors such as the scale of the project, duration, and availability of skilled labor. While steel formwork may have higher upfront costs, the long-term benefits of durability, reusability, and improved construction efficiency can outweigh these initial expenses and positively impact the overall construction cost estimate.

- Q: How does steel formwork affect the overall sustainability of a concrete structure?

- Steel formwork can have a significant impact on the overall sustainability of a concrete structure. Firstly, steel formwork is reusable, which means that it can be used for multiple construction projects, reducing the need for additional materials and minimizing waste. This reusability also helps reduce the environmental impact associated with the production and disposal of formwork materials. Additionally, steel formwork is durable and robust, which ensures that it can withstand repeated use without compromising its structural integrity. This durability extends the lifespan of the formwork, reducing the need for frequent replacements and further reducing waste generation. Furthermore, steel formwork provides superior strength and stability, allowing for the construction of concrete structures with greater precision and efficiency. This facilitates the use of less concrete, reducing the overall carbon footprint of the structure. Additionally, the use of steel formwork can result in faster construction times, minimizing energy consumption and reducing the project's environmental impact. Moreover, steel formwork allows for greater flexibility in design and construction techniques, enabling the creation of more sustainable structures. It can be easily customized to fit various shapes and sizes, optimizing the use of space and reducing material wastage. This flexibility also allows for the integration of sustainable features such as energy-efficient insulation, green roofs, or rainwater harvesting systems. In summary, steel formwork positively impacts the overall sustainability of a concrete structure through its reusability, durability, strength, and flexibility. By reducing waste generation, minimizing the use of concrete, and enabling sustainable design options, steel formwork contributes to the creation of more environmentally-friendly and efficient structures.

- Q: What are the considerations when designing steel formwork for tunnels?

- When designing steel formwork for tunnels, there are several important considerations that need to be taken into account. Firstly, the structural integrity of the formwork is crucial. The steel formwork needs to be able to withstand the forces exerted by the surrounding soil and the weight of the concrete being poured. It should be designed to be strong enough to prevent any deformation or collapse during the construction process. Secondly, the dimensions and shape of the tunnel need to be carefully considered. The formwork should be designed to match the exact dimensions and curvature of the tunnel to ensure a precise fit. This will help to ensure that the final concrete structure is of the correct size and shape. Thirdly, the formwork needs to be designed in a way that allows for easy installation and removal. This is particularly important in tunnel construction, where access can be limited and space is often restricted. The formwork should be designed to be easily assembled and disassembled, with minimal disruption to the construction process. Another consideration when designing steel formwork for tunnels is the surface finish of the concrete. The formwork should be designed to provide a smooth and even surface, as any imperfections or irregularities in the formwork can be transferred to the concrete. This is important for both aesthetic reasons and to ensure the structural integrity of the final concrete structure. Lastly, the formwork should be designed in a way that allows for proper ventilation and drainage. Tunnels can be prone to moisture accumulation, which can lead to corrosion and deterioration of the steel formwork. Proper ventilation and drainage systems should be incorporated into the design to prevent any moisture-related issues. In conclusion, when designing steel formwork for tunnels, it is important to consider the structural integrity, dimensions and shape, ease of installation and removal, surface finish, and ventilation/drainage requirements. By carefully addressing these considerations, the design of the steel formwork can be optimized to ensure a successful and efficient tunnel construction process.

- Q: Can steel formwork be used for structures with high thermal insulation requirements?

- Steel formwork is not typically used for structures with high thermal insulation requirements. This is because steel is a good conductor of heat, meaning it allows heat to easily transfer through it. As a result, using steel formwork in structures that require high thermal insulation would lead to significant heat loss, reducing the overall energy efficiency of the building. To achieve high thermal insulation, materials with good thermal resistance such as insulating concrete forms (ICFs), expanded polystyrene (EPS), or other insulated formwork systems are preferred. These materials have low thermal conductivity and provide a barrier against heat transfer. By using such materials, structures can meet the high thermal insulation requirements and improve energy efficiency. However, it is worth mentioning that steel formwork can still be used in combination with insulation materials to provide structural support and form the shape of the structure. In this case, additional insulation measures, such as applying insulation layers or using insulation inserts, would be necessary to enhance the thermal performance of the structure. Overall, while steel formwork can be suitable for many construction projects, it is not the ideal choice for structures with high thermal insulation requirements.

Send your message to us

Steel-frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords