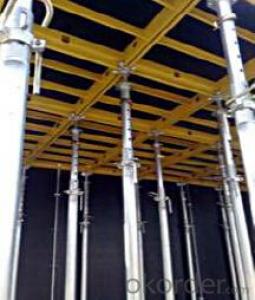

Steel-frame Formwork system and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

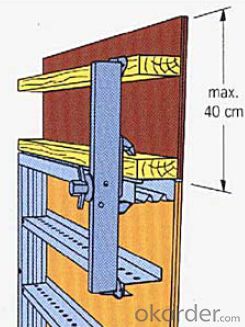

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork handle concrete curing time?

- Concrete curing time is efficiently and effectively managed by steel formwork. Sturdy and durable steel plates are used to construct the formwork, providing excellent support and stability during pouring and curing. The steel plates are specifically designed to withstand the weight and pressure of the wet concrete, ensuring that the formwork remains intact and in position until the concrete is fully cured. This prevents any deformation or collapse of the formwork structure, which could compromise the quality and integrity of the final concrete structure. In addition, the smooth and non-absorbent surface of the steel formwork minimizes moisture loss from the concrete during the curing process. This is crucial as maintaining proper moisture levels is essential for the concrete to achieve optimal strength and durability. Moreover, steel formwork allows for easy and efficient removal once the concrete has cured. The steel plates can be easily dismantled and reassembled for subsequent concrete pours, reducing overall construction time and cost. In summary, steel formwork offers a dependable and robust solution for managing concrete curing time. It ensures the structural integrity of the formwork during curing, maintains appropriate moisture levels for optimal concrete strength, and allows for efficient removal once the concrete is fully cured.

- Q: How does steel formwork improve the quality of concrete structures?

- Steel formwork is widely employed in the construction industry due to its numerous advantages, which greatly enhance the quality of concrete structures. Here are several ways in which steel formwork improves the quality of concrete structures: 1. Superior Form Stability: Compared to traditional wooden formwork, steel formwork offers enhanced form stability. It is more rigid and less prone to warping or distortion, guaranteeing that the concrete is poured into an accurate and consistent shape. This results in straighter walls, smoother surfaces, and overall better structural integrity. 2. Increased Durability: Steel formwork is highly durable and capable of withstanding the harsh conditions of construction sites. Unlike wooden formwork, it does not rot, decay, or easily sustain damage. Its long lifespan allows for multiple reuses, thereby reducing costs and waste. This durability translates into stronger and longer-lasting concrete structures. 3. Precise Dimensions: Steel formwork is manufactured with high precision, enabling accurate and consistent dimensions in concrete structures. It facilitates achieving the desired shape, size, and alignment of elements. This accuracy is crucial in ensuring that the structure meets required specifications and architectural designs, resulting in a high-quality finished product. 4. Improved Surface Finish: Steel formwork provides a smooth and even surface finish to concrete structures. The design of steel panels minimizes surface imperfections and prevents leakage of the concrete mixture. This results in visually appealing structures with uniform finishes, which reduces the need for additional plastering or finishing work. 5. Enhanced Safety: Steel formwork enhances safety during the construction process. Its sturdy and rigid nature provides a stable platform for workers to pour and work with concrete. The risk of accidents, such as formwork failure or collapse, is significantly reduced with steel formwork, ensuring the safety of workers and the integrity of the structure. In conclusion, the utilization of steel formwork in concrete construction brings multiple benefits that contribute to the improvement of structure quality. With its form stability, durability, precise dimensions, improved surface finish, and enhanced safety, steel formwork plays a vital role in ensuring the integrity, aesthetics, and longevity of concrete structures.

- Q: How does steel formwork handle concrete surface blemishes?

- Steel formwork is a popular choice for construction projects due to its durability and strength. When it comes to handling concrete surface blemishes, steel formwork offers several advantages. Firstly, the smooth and rigid surface of steel formwork helps minimize the occurrence of surface blemishes on the concrete. Unlike other formwork materials such as timber, steel does not warp or deform easily, ensuring a consistent and even surface for the concrete to be poured onto. This reduces the chances of surface imperfections like air pockets, formwork marks, or uneven textures. Moreover, steel formwork allows for precise control over the concrete pouring process. The steel panels are manufactured with high precision, ensuring accurate dimensions and alignment. This precision, coupled with the tight joints and connections between the panels, minimizes the likelihood of concrete seepage or leakage, which can lead to surface blemishes such as honeycombing or efflorescence. Additionally, steel formwork can be easily cleaned and maintained, which further contributes to preventing or handling concrete surface blemishes. The smooth surface of steel allows for easy removal of any excess concrete or debris that might accumulate during the pouring process. This prevents the formation of unwanted blemishes and preserves the quality of the concrete surface. In cases where concrete surface blemishes do occur, steel formwork offers the advantage of being reusable. Unlike other formwork materials that may need to be discarded after a single use, steel formwork can be easily cleaned, repaired, and reused for multiple projects. This allows for more control over the quality of the formwork, reducing the risk of surface blemishes in subsequent concrete pours. In conclusion, steel formwork handles concrete surface blemishes effectively by providing a smooth and rigid surface, precise control over the pouring process, easy maintenance and cleaning, and reusability. These features contribute to achieving a high-quality concrete surface with minimal blemishes, ensuring a visually appealing and structurally sound end result.

- Q: Can steel formwork be customized for specific project requirements?

- Customization of steel formwork is possible to meet the specific requirements of a project. Steel, being highly versatile, can be shaped and molded easily to fit the unique needs of a project. This flexibility allows for the creation of different sizes, shapes, and designs to accommodate varying construction needs. On-site modification or adjustment of steel formwork is also achievable to align with the exact dimensions and specifications of a project. Furthermore, off-site pre-fabrication of steel formwork, tailored precisely to the project's requirements, is an option before transporting it to the construction site. By customizing steel formwork, it becomes suitable for a wide range of construction projects, including intricate structures, tall buildings, bridges, tunnels, and more.

- Q: Can steel formwork be used for soundproofing walls?

- Steel formwork is primarily used for creating the structure and shape of concrete walls during construction. While steel formwork is sturdy and durable, it is not specifically designed for soundproofing purposes. Soundproofing walls typically require materials with high acoustic performance and insulation properties to effectively block or absorb sound waves. While steel formwork may offer some level of sound reduction due to its density, it is not sufficient for achieving significant soundproofing results. To effectively soundproof walls, it is recommended to use specialized materials such as acoustic insulation, mass-loaded vinyl, or soundproof drywall, which are designed specifically for this purpose.

- Q: How does steel formwork affect the overall noise transmission in the building?

- Steel formwork can have a positive impact on reducing noise transmission in a building. Its solid and dense structure acts as a barrier, effectively blocking the transmission of sound waves. Additionally, steel formwork is known for its excellent vibration-damping properties, further minimizing noise transmission. Therefore, by using steel formwork, the overall noise levels within the building can be significantly reduced, resulting in a more peaceful and comfortable environment for occupants.

- Q: How does steel formwork affect the overall thermal insulation of a building?

- Steel formwork does not directly impact the overall thermal insulation of a building. The purpose of steel formwork is to provide structural support during the construction process, allowing the concrete to be poured and shaped into the desired form. It is a temporary structure that is removed after the concrete has cured. Thermal insulation in a building is primarily determined by the materials used in the walls, roof, and floors, as well as the design and installation of insulation systems. These materials and systems are separate from the steel formwork used during construction. However, it is worth noting that the use of steel formwork may have an indirect effect on the thermal insulation of a building. The construction process itself, including the use of formwork, can impact the overall quality of the insulation installation. If not properly managed, the installation of insulation materials during or after the removal of steel formwork may be compromised, leading to gaps, voids, or poor installation that can affect thermal insulation. Therefore, it is essential to ensure that proper construction practices are followed, and insulation materials are correctly installed after the removal of steel formwork. This will help maintain the intended thermal insulation performance of the building.

- Q: What is the difference between the steel template and the wood template? When to use steel formwork? When to use a wooden template?Now what kind of use

- Can use a combination of steel templates can also be used in large format steel formwork

- Q: Can steel formwork be customized to meet specific project requirements?

- Yes, steel formwork can be customized to meet specific project requirements. Steel formwork is a versatile and flexible construction material that can be easily modified and adjusted to fit different shapes, sizes, and dimensions. It can be cut, welded, and reshaped to match the specific requirements of a project. Additionally, steel formwork allows for the creation of complex and intricate structures, making it suitable for a wide range of construction projects. The customization of steel formwork enables builders and contractors to achieve precise and accurate results, ensuring that the final structure meets the desired specifications and design requirements.

- Q: Can steel formwork be used for airport runway construction?

- Yes, steel formwork can be used for airport runway construction. Steel formwork is a versatile and durable option for creating concrete structures, including runways. It offers several advantages over other types of formwork, such as timber or aluminum. Firstly, steel formwork provides a high level of strength and stability, ensuring that the concrete pouring process is efficient and accurate. This is crucial for runway construction, as the surface needs to be even and strong enough to withstand heavy aircraft traffic. Secondly, steel formwork is reusable, making it cost-effective for large-scale projects like airport runways. Its durability allows it to be used multiple times, reducing the need for frequent replacements and saving both time and money. Additionally, steel formwork can be easily assembled and disassembled, making it convenient for construction sites with tight schedules or limited space. Its modular design allows for quick installation and adjustment, enabling efficient construction progress. Furthermore, steel formwork provides excellent resistance to various weather conditions, including extreme temperatures and moisture. This is vital for airport runways, as they are exposed to constant wear and tear from aircraft, as well as harsh weather conditions. In conclusion, steel formwork is a suitable choice for airport runway construction due to its strength, reusability, ease of use, and resistance to different weather conditions. Its ability to provide a stable and durable surface makes it an ideal option for creating runways capable of handling heavy aircraft traffic.

Send your message to us

Steel-frame Formwork system and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords