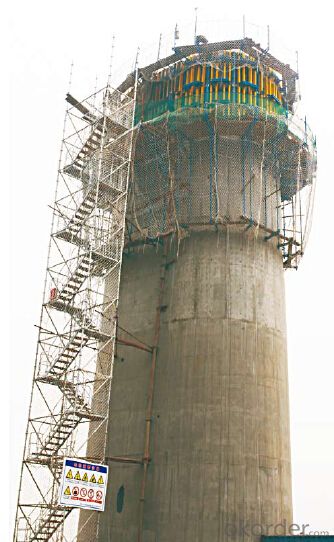

Stair-tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used for both standard and non-standard concrete shapes?

- Indeed, both standard and non-standard concrete shapes can be accommodated by steel formwork. The adaptability of steel as a material enables it to be effortlessly molded and manipulated to produce diverse formwork patterns. Furthermore, its robustness and enduring nature render it appropriate for intricate and intricate concrete shapes. Steel formwork can be tailor-made to satisfy precise project specifications, thus offering flexibility and customization in formwork design. Regardless of whether the desired shape is a conventional rectangle or an exceptional and unconventional design, steel formwork can proficiently be employed to shape and mold concrete structures of various dimensions and configurations.

- Q: What materials are used in steel formwork construction?

- Steel formwork construction typically involves the use of various materials to create a sturdy and durable structure. The primary material used in steel formwork is, as the name suggests, steel. This is because steel offers excellent strength and rigidity, making it ideal for supporting the weight and pressure exerted by the concrete during the casting process. In addition to steel, other materials are also used in steel formwork construction. One common material is plywood or timber, which is used to create the formwork panels. These panels are typically made of high-quality plywood or timber boards that are strong enough to hold the weight of the concrete without bending or warping. To further reinforce the formwork structure, steel bars or rods are often used. These reinforcement bars are strategically placed within the formwork to provide additional support and prevent any deformation or collapse of the structure during the concrete pouring process. Other materials used in steel formwork construction include various types of connectors, fasteners, and accessories. These may include bolts, nuts, clamps, wedges, and pins, among others. These components are used to securely join and hold the formwork panels and reinforcement bars together, ensuring a stable and rigid structure. Overall, steel formwork construction requires a combination of steel, plywood or timber, reinforcement bars, and various connectors and accessories. These materials work together to create a robust and reliable formwork system that can withstand the pressures and forces exerted during the concrete casting process.

- Q: Is steel formwork suitable for projects with limited access?

- Yes, steel formwork is suitable for projects with limited access. Steel formwork is known for its strength and durability, allowing it to be easily transported and assembled in confined spaces. Additionally, steel formwork can be customized to fit specific project requirements, making it an ideal choice for projects with limited access.

- Q: Can steel formwork be used for structures with high wind resistance requirements?

- Yes, steel formwork can be used for structures with high wind resistance requirements. Steel is a strong and durable material that can withstand high wind forces, making it suitable for constructing buildings and structures that need to resist strong winds.

- Q: Can steel formwork be used for power plant construction projects?

- Yes, steel formwork can be used for power plant construction projects. Steel formwork is a versatile and durable solution for creating concrete structures in various industries, including power plant construction. It offers several advantages such as high strength, easy assembly and disassembly, and the ability to withstand heavy loads and extreme weather conditions. Steel formwork can be customized to meet the specific requirements of power plant construction, allowing for the creation of complex and precise concrete components. Additionally, steel formwork can be reused multiple times, making it a cost-effective and sustainable choice for power plant projects.

- Q: How does steel formwork contribute to the overall durability of a structure?

- Steel formwork contributes to the overall durability of a structure by providing a strong and rigid framework during the concrete pouring process. It ensures accurate and precise shaping of the concrete, resulting in a solid and uniform structure. Steel formwork is highly resistant to warping, bending, and cracking, making it more durable than other types of formwork materials. Its strength and durability allow for multiple reuse, reducing construction costs and minimizing waste. Additionally, steel formwork provides excellent support for the concrete as it cures, preventing any deformation or collapse. Overall, steel formwork plays a crucial role in enhancing the longevity and robustness of a structure.

- Q: What are the different accessories required for steel formwork maintenance?

- The following are the various accessories needed to maintain steel formwork: 1. To maintain the smooth surface of the formwork and prevent corrosion or damage, formwork cleaning agents are used to remove any concrete residue or build-up on the steel formwork. 2. Prior to pouring concrete, formwork release agents are applied to the steel formwork to prevent it from sticking. This makes it easier to remove the formwork once the concrete has cured. 3. Formwork patching compounds are used to fix any damages or imperfections on the steel formwork. This helps maintain the formwork's structural integrity and ensure its longevity. 4. To ensure smooth operation and prevent friction or wear and tear, formwork oil or grease is applied to the moving parts of the steel formwork, such as hinges or sliding mechanisms. 5. Formwork ties and connectors are used to secure the formwork panels together during concrete pouring, ensuring stability. They should be regularly inspected and replaced if damaged or worn out. 6. Formwork wedges and pins are used to align and secure the formwork panels in place. Regular checks should be done to ensure proper positioning and stability. 7. Formwork clamps and brackets are accessories used to support and hold the formwork panels in position. They should be inspected for any signs of damage or weakness and replaced if necessary. 8. To clean the steel formwork and prevent the accumulation of dirt or debris, formwork cleaning tools such as brushes, scrapers, and high-pressure washers are used. 9. Racks, trolleys, or storage containers are used as storage and transportation equipment for the steel formwork. Proper storage and transportation ensure the formwork's longevity and prevent any damage or distortion. In summary, the various accessories needed for steel formwork maintenance are essential for optimal performance, durability, and safety during concrete construction projects.

- Q: What is the 86 series steel formwork

- Steel template (also called undismantled Mould Network) can replace the wood template, significantly reduced usually with wood, plywood, steel plate or other traditional sealing template on the pore water pressure and the pressure in the bubble concrete elimination; steel template (undismantled Mould Network) structure of concrete casting, forming an ideal rough interface. Do not need to rough cutting operations can enter the next construction processThe utility model can be placed before installing the reinforcing steel bar, and can also be placed after installing the reinforcing steel bar. If it is installed before the installation of steel, easy installation and easy to install; concrete pouring process can be visually monitored, thereby reducing the risk of the emergence of pores and honeycomb structure and other phenomena.

- Q: How does steel formwork affect the overall construction site aesthetics?

- The overall aesthetics of a construction site can be significantly impacted by the use of steel formwork. In contrast to traditional timber formwork, steel formwork offers a sleek and contemporary look. The smooth and pristine surfaces of steel formwork convey a sense of precision and professionalism to the construction site. Moreover, the utilization of steel formwork provides greater design flexibility. It can be effortlessly shaped and molded into intricate forms, resulting in visually appealing and one-of-a-kind structures. This flexibility empowers architects and designers to create innovative and captivating architectural elements that enhance the overall aesthetics of the construction site. Furthermore, steel formwork plays a role in maintaining the cleanliness of the construction site. Its durable and reusable nature minimizes waste generated during the construction process. This not only contributes to a cleaner and more organized site, but also reduces the environmental impact of the construction process. Additionally, steel formwork instills a sense of durability and strength to the construction site. Its sturdy nature ensures that the structures being constructed are solid and long-lasting. This further enhances the impression of quality and stability, ultimately improving the aesthetics of the construction site. In conclusion, the use of steel formwork has a positive impact on the overall aesthetics of a construction site. It provides a modern and sleek appearance, enables flexible and innovative designs, contributes to cleanliness, and enhances the sense of durability and strength.

- Q: How does steel formwork contribute to the overall safety of the construction process?

- Steel formwork contributes to the overall safety of the construction process by providing a sturdy and stable structure for concrete pouring. Its strength and durability minimize the risk of accidents caused by collapsing or shifting formwork. Additionally, steel formwork is fire-resistant, reducing the likelihood of fire hazards on the construction site. Its reusable nature also reduces waste and potential environmental hazards, ensuring a safer working environment for construction workers.

Send your message to us

Stair-tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords