Adjustable Arced formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

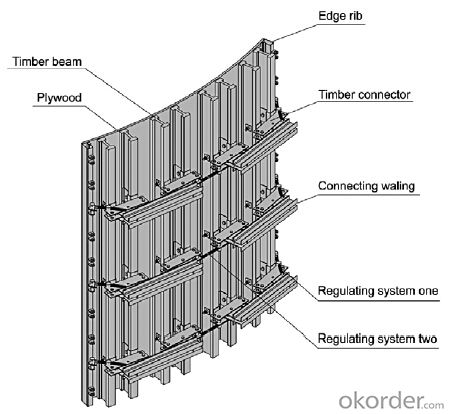

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: How does steel formwork handle concrete vibration during pouring?

- Steel formwork is a versatile and durable construction material that is commonly used in concrete pouring processes. When it comes to handling concrete vibration during pouring, steel formwork has several advantages. Firstly, steel formwork is known for its high strength and rigidity, which allows it to withstand the intense vibrations caused by the pouring of concrete. The robustness of steel formwork ensures that it remains stable and in place during the vibration process, preventing any potential deformation or collapse that could occur with weaker materials. Additionally, steel formwork is designed with interlocking systems and tight joints that help to minimize the potential for concrete leakage. This ensures that the concrete remains contained within the formwork, allowing for a more efficient pouring process and reducing the need for excessive clean-up or rework. Moreover, steel formwork is capable of transmitting vibrations efficiently throughout its structure. This is advantageous as the vibrations help to eliminate air bubbles and voids within the concrete, resulting in a more uniform and compact final product. The ability of steel formwork to effectively transmit vibrations aids in achieving a higher level of concrete compaction, which enhances the overall strength and durability of the structure. Lastly, steel formwork is highly reusable and can be easily disassembled and reused for multiple projects. This is advantageous in terms of cost-effectiveness and sustainability, as it reduces the need for constant replacement of formwork materials. The ability to reuse steel formwork also means that its effectiveness in handling concrete vibration remains consistent over time. Overall, steel formwork is a reliable and efficient material for handling concrete vibration during pouring. Its strength, stability, and ability to transmit vibrations make it a preferred choice in construction projects where concrete pouring and compaction are required.

- Q: Can steel formwork be used for both small-scale and large-scale construction projects?

- Yes, steel formwork can be used for both small-scale and large-scale construction projects. Its strength and durability make it suitable for various types of projects, regardless of their size. Additionally, steel formwork offers flexibility and can be easily customized to meet the specific requirements of different construction projects, making it a versatile choice for both small and large-scale construction.

- Q: Can steel formwork be used for hotel construction projects?

- Yes, steel formwork can be used for hotel construction projects. Steel formwork is commonly used in construction due to its durability, strength, and versatility. It provides a sturdy and reliable framework for pouring concrete and can be easily assembled and dismantled, making it suitable for various construction projects, including hotel buildings.

- Q: Are there any safety concerns associated with steel formwork?

- Steel formwork presents a number of safety concerns. One major issue is the weight of the steel panels, as they can be quite heavy and pose a risk to workers during installation and removal. To handle the panels safely, workers must follow proper lifting techniques and utilize equipment like cranes or forklifts. Another concern revolves around the risk of falls, especially when steel formwork is used for high-rise buildings. To prevent accidents, it is essential to implement fall protection measures such as guardrails, safety nets, or personal fall arrest systems. Moreover, steel formwork may have sharp edges or protruding parts that can lead to injuries if mishandled. Reducing the risk of cuts, bruises, or other injuries requires proper training on handling and assembling the formwork. In addition, welding or cutting may be necessary during the installation or modification of steel formwork, introducing hazards like sparks, fumes, or fire. To mitigate these risks, it is crucial to ensure adequate ventilation, wear appropriate personal protective equipment, and adhere to safe welding practices. Lastly, electrical hazards can arise if steel formwork comes into contact with overhead power lines or if electrical tools and equipment are used nearby. Identifying potential electrical hazards and implementing safety measures such as isolating power sources and following safe work practices is vital to prevent electrical accidents. While steel formwork offers numerous advantages in construction projects, it is vital to acknowledge these safety concerns and take necessary precautions to protect workers and maintain a safe work environment.

- Q: Can steel formwork be used for theater construction projects?

- Yes, steel formwork can be used for theater construction projects. Steel formwork offers durability, strength, and flexibility, making it suitable for creating complex shapes and structures required in theater construction. It provides a solid framework for creating stages, seating areas, and other components of theater spaces. Additionally, steel formwork can be easily reused and adjusted to meet the specific design requirements of theater projects.

- Q: What are the different steel grades used in steel formwork?

- There are several different steel grades that are commonly used in steel formwork, each with their own specific characteristics and advantages. Some of the most common steel grades used in steel formwork include: 1. Mild Steel (Grade 250): Mild steel is a low carbon steel that is relatively inexpensive and easy to work with. It offers good strength and durability, making it suitable for many construction applications. However, it may not have the same level of resistance to corrosion as other steel grades. 2. High Tensile Steel (Grade 500): High tensile steel is a type of steel that has a higher strength-to-weight ratio compared to mild steel. It offers superior strength and durability, making it suitable for heavy-duty applications. High tensile steel is often used in formwork for structures that require greater load-bearing capacity. 3. Stainless Steel: Stainless steel is a corrosion-resistant alloy that contains a minimum of 10.5% chromium. It offers excellent resistance to corrosion, making it ideal for formwork that will be exposed to harsh environmental conditions or chemicals. Stainless steel also has a high strength-to-weight ratio and is often used in marine and chemical industry applications. 4. Weathering Steel (Grade 350): Weathering steel, also known as corten steel, is a high-strength, low-alloy steel that forms a protective layer of rust when exposed to the elements. This protective layer helps to prevent further corrosion, making it suitable for formwork in outdoor environments. Weathering steel is often used in bridge construction and other infrastructure projects. 5. Galvanized Steel: Galvanized steel is steel that has been coated with zinc to provide protection against corrosion. The zinc coating acts as a barrier, preventing moisture and oxygen from reaching the underlying steel. Galvanized steel formwork is commonly used in concrete construction, as it offers excellent corrosion resistance and durability. Overall, the choice of steel grade for steel formwork will depend on various factors including the specific application, load-bearing requirements, and environmental conditions. It is important to select the appropriate steel grade to ensure the longevity and performance of the formwork system.

- Q: What are the limitations of using steel formwork?

- Using steel formwork in construction projects has several limitations. Firstly, it is a relatively expensive option compared to materials like wood or aluminum, which can significantly increase construction costs for large-scale projects. Secondly, the heaviness of steel formwork necessitates the use of heavy machinery and equipment for transportation and installation. This can pose challenges in areas with limited access or on sites with uneven terrain. In addition, skilled labor is required for the proper installation and dismantling of steel formwork. If the workforce lacks experience in working with steel formwork, this can lead to delays and increased labor costs. Furthermore, steel formwork is not as flexible as other materials, which can limit design possibilities for complex or irregular shapes. Another drawback is the potential for corrosion. Steel formwork is susceptible to rust and corrosion, particularly in environments with high moisture or chemical exposure. Regular maintenance and corrosion protection measures are necessary to ensure the longevity of steel formwork. Lastly, steel formwork is not as environmentally friendly as other alternatives. The production of steel involves significant energy consumption and carbon emissions, contributing to environmental degradation. Overall, while steel formwork offers strength and durability, it is important to carefully consider its limitations in terms of cost, weight, flexibility, corrosion susceptibility, and environmental impact before selecting it for construction projects.

- Q: Is steel formwork suitable for projects with heavy concrete loads?

- Yes, steel formwork is suitable for projects with heavy concrete loads. Steel is a strong and durable material that can withstand the weight and pressure of heavy concrete loads without deformation or damage, making it an ideal choice for such projects.

- Q: Can steel formwork be used for both above-ground and below-ground structures?

- Yes, steel formwork can be used for both above-ground and below-ground structures.

- Q: How does steel formwork affect the concrete curing process?

- Construction projects commonly utilize steel formwork as temporary molds for pouring concrete, and its presence can have a significant impact on the curing process of the concrete. To begin with, the utilization of steel formwork allows for better control over the shape and dimensions of the concrete structure, thanks to its smooth and rigid surface. This results in even and uniform pouring of the concrete, leading to a more consistent curing process. Additionally, the smooth surface of the steel formwork aids in achieving a superior finish on the concrete surface. Furthermore, steel formwork provides stability and support to the concrete during the curing process, preventing any sagging or deformation caused by its own weight, particularly in vertical or overhead structures. This support enables the concrete to cure properly, devoid of any distortions or cracks, ultimately resulting in a structurally sound and durable final product. Moreover, the presence of steel formwork acts as a barrier, preventing the loss of moisture from the concrete during curing. Adequate moisture is crucial for the proper hydration of cement particles, which is essential for attaining the desired strength and durability of the concrete. By retaining moisture and creating a favorable environment for the curing process, steel formwork reduces the risk of shrinkage and cracking. Furthermore, steel formwork also has the ability to influence the curing time of the concrete. Its high thermal conductivity allows for the dissipation of heat from the concrete, thereby expediting the curing process. This feature can be advantageous in specific situations where faster curing is required, such as in cold weather conditions or time-sensitive construction projects. In conclusion, the presence of steel formwork is vital in the concrete curing process due to its ability to provide a smooth surface, stability, moisture retention, and influence on the curing time. By ensuring a consistent and high-quality curing process, steel formwork contributes to the creation of durable and well-finished concrete structures.

Send your message to us

Adjustable Arced formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords