Steel-frame corner link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

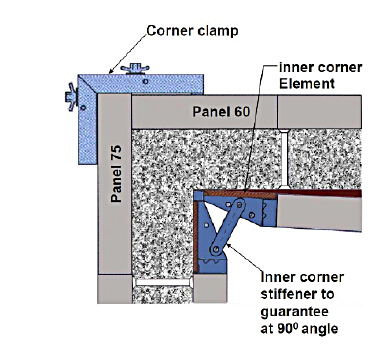

◆ The selection of panels.

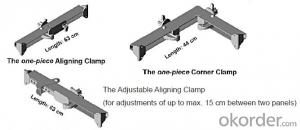

◆ Kinds of panel connectors.

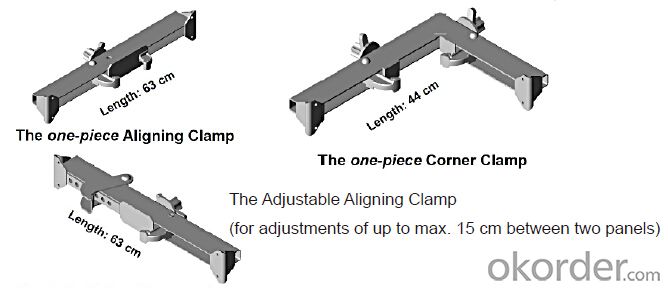

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for architectural concrete columns?

- Architectural concrete columns can indeed utilize steel formwork. Renowned for its robustness and endurance, steel formwork is an appropriate selection when it comes to erecting concrete columns. With its inflexible structure, it successfully withstands the pressure exerted by the liquid concrete throughout the pouring and hardening processes. Furthermore, steel formwork enables architects to fashion intricate designs and textures on the surface of the concrete columns, thanks to its capacity for precise shaping and detailing. Moreover, steel formwork can be reused numerous times, making it a cost-effective alternative for projects necessitating multiple concrete columns. Nevertheless, it is crucial to ensure that the steel formwork is adequately coated or treated to prevent corrosion and guarantee its longevity.

- Q: What are the different sizes available for steel formwork panels?

- The sizes available for steel formwork panels can vary depending on the manufacturer and project requirements. However, common sizes range from 1.2 meters by 1.8 meters to 2.4 meters by 4.8 meters. These dimensions can be adjusted to accommodate different construction needs and can be found in various thicknesses and configurations.

- Q: Is steel formwork suitable for projects with limited construction space?

- Indeed, projects with limited construction space can benefit greatly from the utilization of steel formwork. Renowned for its adaptability and capacity to be tailored to different project specifications, especially those constrained by space restrictions, steel formwork stands as a lightweight and resilient alternative. Its inherent feasibility in terms of assembly, disassembly, and mobility further contributes to optimal space utilization. Moreover, steel formwork guarantees a remarkable level of precision and accuracy, facilitating a seamless and efficient construction process within the confines of limited space.

- Q: How does steel formwork affect the overall thermal performance of the structure?

- Steel formwork does not significantly affect the overall thermal performance of a structure as steel is a good conductor of heat. However, it can indirectly impact thermal performance by providing a solid structure that helps in maintaining insulation materials in place, thereby improving the overall energy efficiency of the building.

- Q: Can steel formwork be used in seismic-prone areas?

- Yes, steel formwork can be used in seismic-prone areas. Steel is a strong and durable material that can withstand the forces generated during earthquakes. It provides excellent structural stability and can be easily reinforced to meet the specific requirements of seismic design codes. Additionally, steel formwork offers the advantage of being reusable, making it a cost-effective and practical option for construction projects in seismic-prone areas.

- Q: What are the considerations when designing steel formwork for elevated walkways?

- When designing steel formwork for elevated walkways, there are several important considerations to take into account. These considerations include structural integrity, safety, durability, and ease of installation. Firstly, the structural integrity of the formwork is crucial. The design must be able to support the weight of pedestrians and any additional live loads such as equipment or furnishings. The formwork should be designed to withstand any potential deflection or deformation, ensuring a stable and secure walkway. Safety is another paramount consideration. The formwork should have adequate handrails and guardrails to prevent falls and provide a safe environment for pedestrians. It is important to comply with relevant safety standards and regulations to minimize the risk of accidents or injuries. Durability is also a key consideration when designing steel formwork for elevated walkways. The materials used should be able to withstand exposure to environmental factors such as weather, temperature changes, and corrosion. Proper surface treatments and coatings can help enhance the durability of the formwork, extending its lifespan and reducing maintenance requirements. Additionally, ease of installation is an important factor to consider. The formwork should be designed in a way that allows for efficient and straightforward installation, minimizing construction time and costs. Modular designs or pre-fabricated components can help simplify the installation process and ensure consistency in the final structure. Furthermore, it is essential to consider accessibility and inclusivity when designing steel formwork for elevated walkways. The design should accommodate individuals with disabilities, providing appropriate ramps, handrails, and tactile indicators to ensure equal access for all users. Lastly, it is crucial to engage with experienced professionals such as structural engineers and architects during the design process. Their expertise and knowledge can help ensure that all necessary considerations are taken into account, resulting in a well-designed and functional steel formwork for elevated walkways.

- Q: Can steel formwork be used for both regular and irregular concrete structures?

- Yes, steel formwork can be used for both regular and irregular concrete structures. Steel formwork is highly versatile and can be easily customized to fit any shape or size of the structure. This makes it suitable for constructing both regular structures with standard dimensions as well as irregular structures with unique shapes and designs. The flexibility of steel formwork allows for efficient construction of various types of concrete structures, including walls, columns, beams, slabs, and even complex architectural features. Additionally, steel formwork offers high strength and durability, ensuring that it can withstand the pressure and weight of the concrete during the pouring and curing process, regardless of the structure's regular or irregular shape. Overall, steel formwork is a reliable and adaptable choice for constructing both regular and irregular concrete structures.

- Q: How does steel formwork contribute to improved construction quality?

- Steel formwork is a construction technique that involves the use of steel sheets or panels to create temporary molds for concrete structures. It is widely recognized for its ability to contribute to improved construction quality in several ways. Firstly, steel formwork offers high precision and accuracy in shaping concrete structures. The steel panels are manufactured to precise dimensions, ensuring that the final concrete structure is built according to the desired specifications. This level of precision minimizes the risk of errors and inconsistencies, resulting in a higher-quality construction. Secondly, steel formwork provides excellent durability and stability. Unlike traditional wooden formwork, steel formwork can withstand extreme weather conditions, heavy loads, and repeated use without warping or deforming. This durability ensures that the formwork remains intact throughout the construction process, preventing any potential issues that may arise from a compromised formwork system. Additionally, steel formwork allows for faster construction cycles compared to other formwork materials. The ease of assembly and disassembly, along with the ability to reuse the formwork on multiple projects, significantly reduces construction time. This efficiency not only saves construction companies time but also minimizes disruptions to neighboring sites and reduces costs associated with extended construction periods. Moreover, steel formwork enhances construction quality by providing a smooth and uniform finish to concrete structures. The steel panels create a seamless mold, eliminating the need for excessive remedial work such as plastering or patching. This results in a visually appealing and aesthetically pleasing final product, which is crucial for projects that require high-quality finishes. Furthermore, steel formwork allows for greater flexibility in design and construction. The modular nature of steel panels enables architects and engineers to create complex and intricate structures with ease. This versatility enables the construction of unique and innovative designs, enhancing the overall quality and visual appeal of the project. In conclusion, steel formwork significantly contributes to improved construction quality by providing high precision, durability, efficiency, and flexibility. Its ability to create accurate molds, withstand external forces, reduce construction time, and produce seamless finishes ensures that the final concrete structures meet the highest standards of quality and durability.

- Q: Can steel formwork be used in seismic zones?

- Steel formwork is indeed capable of being employed in seismic zones. Steel possesses formidable strength and durability, enabling it to endure the formidable forces unleashed during an earthquake. The material exhibits a remarkable ability to flex and absorb energy, rendering it highly suitable for deployment in seismic zones. Furthermore, steel formwork confers stability and rigidity upon the structure, guaranteeing its ability to withstand the quivering and shifting caused by seismic activity. Nonetheless, it is essential to take into account other factors such as design, construction techniques, and local building codes to ensure the correct installation and compliance of the steel formwork system with the specific requirements of the seismic zone.

- Q: Can steel formwork be custom-made?

- Indeed, the option of customizing steel formwork exists. Steel, being an adaptable material, can be effortlessly molded and joined together through welding to produce formwork tailored to suit specific project demands. In situations where conventional formwork systems may prove inadequate due to distinctive design components or intricate geometries, the utilization of custom-made steel formwork is frequently favored in construction endeavors. The customization of steel formwork allows construction firms to ensure a perfect fit, thereby facilitating efficient and precise pouring of concrete, minimizing waste, and preserving time and financial resources. Moreover, the durability and reusability of custom-made steel formwork offer enduring advantages for numerous construction projects in the long run.

Send your message to us

Steel-frame corner link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords