Steel Billet Manufacturers Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet Manufacturers Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

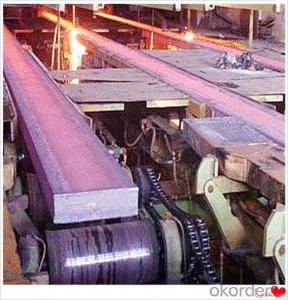

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

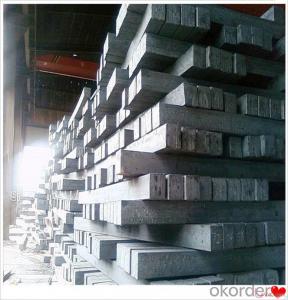

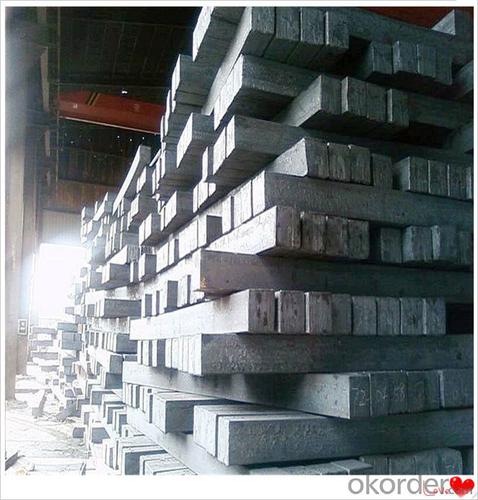

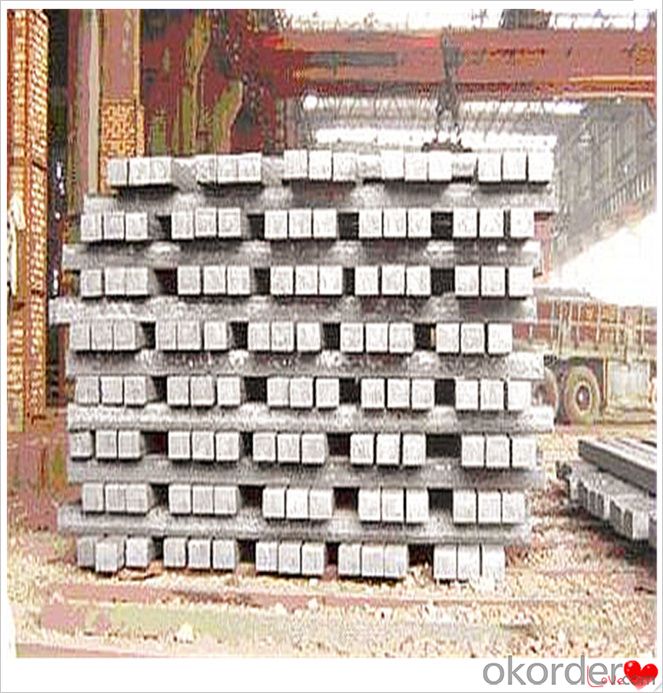

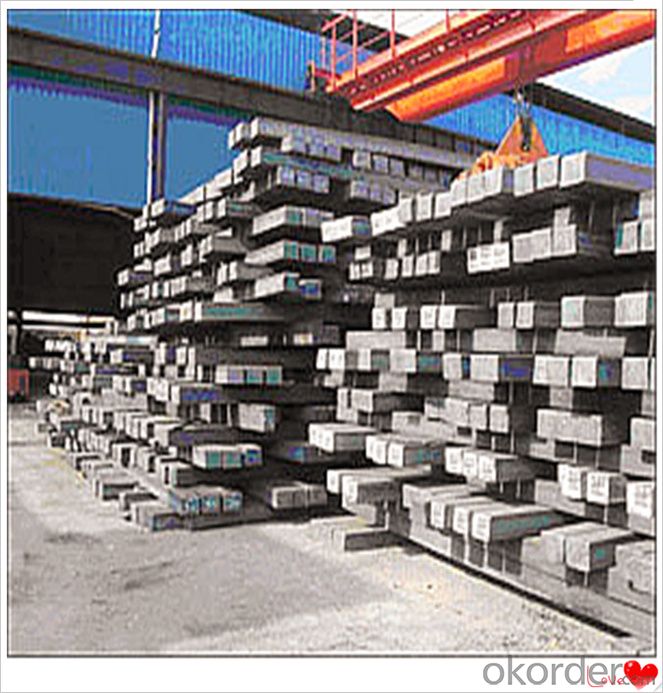

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What is the standard tolerance for steel billet dimensions?

- The specific industry and application can cause variation in the standard tolerance for steel billet dimensions. Generally, the standard tolerance for steel billet dimensions ranges from ±0.005 to ±0.010 inches (±0.13 to ±0.25 mm). These tolerances ensure that the steel billets meet the necessary specifications and standards. It is worth mentioning that different industries and applications might have their own distinct tolerances based on their unique standards and requirements. Thus, it is vital to refer to the relevant industry or application-specific standards to determine the exact tolerance for steel billet dimensions.

- Q: What is the role of steel billets in the production of sheet metal?

- Steel billets play a crucial role in the production of sheet metal. They are the primary raw material used in the manufacturing process. Steel billets are semi-finished products that are created through the process of casting or hot rolling. They are essentially rectangular or square-shaped solid bars of steel. These billets are produced in various sizes and lengths, depending on the specific requirements of the sheet metal being manufactured. The first step in the production of sheet metal involves heating and shaping the steel billets. They are heated to a high temperature and then passed through a series of rolling mills to reduce their thickness and increase their length. The rolling process involves applying pressure to the billets, which causes them to elongate and become thinner. This continuous rolling process is repeated several times until the desired thickness is achieved. Once the steel billets have been rolled into thin sheets, they are further processed to obtain the final sheet metal product. This can involve various additional steps such as cutting, trimming, and surface treatments to enhance the appearance and properties of the sheet metal. Steel billets are preferred in the production of sheet metal due to their excellent mechanical properties. Steel is known for its strength, durability, and malleability, making it an ideal material for sheet metal applications. The use of steel billets ensures that the resulting sheet metal products possess these desirable properties. In summary, steel billets are the starting point in the production of sheet metal. They undergo a series of heating and rolling processes to transform them into thin sheets of steel. These sheets are then further processed to create the final sheet metal products. The use of steel billets allows for the production of sheet metal with superior mechanical properties, making it a critical component in the manufacturing industry.

- Q: What is the role of steel billets in the production of wire rods?

- Steel billets play a crucial role in the production of wire rods. Wire rods are long, cylindrical metal rods that are commonly used in various industrial applications, such as construction, automotive, and manufacturing. The production process of wire rods begins with the melting of steel, which is typically done in an electric arc furnace or a basic oxygen furnace. Once the steel reaches the desired temperature and composition, it is poured into molds to form steel billets. Steel billets are semi-finished products that serve as the starting point for the wire rod manufacturing process. They are solid, rectangular or round bars of steel that undergo further processing to transform them into wire rods. The first step in the conversion of steel billets into wire rods is the reheating process. The billets are heated at a high temperature to make them more malleable and easier to work with. This is typically done in a reheat furnace. After reheating, the billets are passed through a series of rolling mills to reduce their size and shape them into wire rods. These rolling mills use a combination of pressure and heat to deform the steel billets and elongate them into long, thin rods. The process of rolling also helps to improve the mechanical properties of the wire rods, such as their strength and flexibility. Once the wire rods are formed, they may undergo additional treatments, such as cooling, surface treatments, and quality inspections, to meet the specific requirements of different applications. They can be further processed into various products, such as wires, cables, reinforcement bars, or other specialized components. In summary, steel billets are essential in the production of wire rods as they are the starting material that undergoes a series of processing steps, including reheating and rolling, to transform them into the desired shape and properties of wire rods.

- Q: What are the potential defects or flaws in steel billets?

- There are several potential defects or flaws that can occur in steel billets, which can affect the quality and performance of the final product. Some of these defects include: 1. Surface defects: Steel billets can develop surface cracks, scales, or scratches during the manufacturing process. These defects can weaken the material and reduce its structural integrity. 2. Internal defects: Inclusions, such as non-metallic impurities or gas bubbles, can be present within the steel billets. These internal defects can cause localized weaknesses and reduce the overall strength of the material. 3. Segregation: Uneven distribution of alloying elements or impurities can lead to segregation, where certain areas of the billet have different chemical compositions. Segregation can result in inconsistent mechanical properties across the material and decrease its uniformity. 4. Central segregation: This defect occurs when there is a concentration of impurities or alloying elements in the central region of the billet, leading to a weaker core. Central segregation can cause structural failures and reduce the overall reliability of the steel billet. 5. Shrinkage cavities: During the solidification process, shrinkage cavities can form in the steel billet due to the contraction of the molten metal. These cavities can weaken the material and compromise its structural integrity. 6. Surface decarburization: Exposure to high temperatures or improper heat treatment can cause the surface of the steel billet to lose carbon content, resulting in surface decarburization. This defect can reduce the hardness and strength of the material. 7. Laminations: Laminations are thin, elongated voids or layers that can form parallel to the surface of the billet. These defects can weaken the material and make it prone to cracking or failure under stress. 8. Internal cracks: Internal cracks can occur due to improper cooling or handling of the billet during the manufacturing process. These cracks can compromise the structural integrity of the steel billet and potentially lead to catastrophic failure. It is important to detect and address these defects early on to ensure the quality and reliability of the steel billets. Various non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can be utilized to identify and mitigate these potential flaws.

- Q: Are steel billets used in the manufacturing of industrial machinery?

- Yes, steel billets are commonly used in the manufacturing of industrial machinery. They serve as a primary raw material for various components and parts, providing strength, durability, and versatility required in heavy-duty applications.

- Q: What are the main challenges in the storage of steel billets?

- The main challenges in the storage of steel billets include the need for proper space allocation, adequate handling equipment, protection against corrosion and rust, and maintaining optimal temperature and humidity levels. Additionally, ensuring proper inventory management and efficient transportation of the billets can also be challenging.

- Q: Can steel billets be used for making tools?

- Yes, steel billets can be used for making tools. Steel billets are semi-finished products that are typically hot-rolled into bars, rods, or other shapes. These billets have excellent strength, durability, and resistance to wear and tear, making them suitable for tool production. Tools require materials that can withstand high pressures, cutting forces, and repetitive use, and steel billets provide the necessary qualities to meet these requirements. Additionally, steel billets can be further processed through machining, forging, or heat treatment to enhance their properties, allowing for the production of various types of tools such as wrenches, hammers, chisels, and more.

- Q: How do steel billets contribute to the manufacturing of furniture and fixtures?

- Steel billets are used in the manufacturing of furniture and fixtures as they serve as a raw material for various processes such as forging, casting, and extrusion. They can be shaped and molded into different components, such as frames, legs, and supports, which provide strength, durability, and stability to the furniture and fixtures. Additionally, steel billets can be further processed to create different finishes, such as powder coating or painting, to enhance the aesthetic appeal of the final products.

- Q: What are the safety precautions when handling steel billets?

- When handling steel billets, it is important to follow several safety precautions to minimize the risk of accidents and injuries. Firstly, it is crucial to wear appropriate personal protective equipment (PPE) such as safety glasses, steel-toed boots, gloves, and a hard hat. Before handling steel billets, ensure that the work area is clear of any obstacles or debris that could cause trips or falls. Additionally, make sure that the billets are stored and stacked properly to prevent them from falling or shifting unexpectedly. When lifting or moving steel billets, be cautious of their weight and size. Use appropriate lifting equipment such as cranes, forklifts, or hoists to avoid strains or musculoskeletal injuries. Always adhere to the weight limits and load capacities of the equipment being used. Maintain a good grip on the billets to prevent them from slipping or falling. Avoid sharp edges or protruding parts that may cause cuts or puncture wounds. If necessary, use protective covers or padding to prevent contact with sharp or jagged edges. Proper communication is essential when handling steel billets. Ensure that there is clear communication between the workers involved in the process to avoid accidents or mishaps. Use hand signals or radios to communicate effectively, especially in noisy environments. Regularly inspect the steel billets for any defects or damage before handling them. Cracks, rust, or any other issues can compromise the structural integrity of the billets and increase the risk of accidents. If any defects are detected, report them to a supervisor and follow the appropriate procedures for handling or disposing of the billets. Lastly, always be aware of your surroundings and the movements of other workers when handling steel billets. Avoid standing or working in the swing radius of lifting equipment or near moving machinery to prevent being struck or crushed. By following these safety precautions, the risk of accidents and injuries while handling steel billets can be significantly reduced, creating a safer work environment.

- Q: What are the potential applications of steel billets in the aerospace aftermarket?

- Steel billets have a wide range of potential applications in the aerospace aftermarket. These applications include but are not limited to the production of various aerospace components such as engine parts, airframe structures, landing gear components, and fasteners. One potential application of steel billets in the aerospace aftermarket is the manufacturing of engine parts. Steel billets can be used to produce critical components such as turbine blades, compressor discs, and shafts. These parts require high strength, durability, and resistance to extreme temperatures, all of which can be achieved through the use of steel billets. Additionally, steel billets can be used to produce exhaust system components, such as manifolds and flanges, which also require high temperature resistance. Another important application of steel billets in the aerospace aftermarket is in the production of airframe structures. Steel billets can be utilized to manufacture various structural components, including beams, frames, and brackets. These components are crucial for providing strength and stability to the aircraft's fuselage, wings, and other structural elements. Steel billets offer the necessary strength-to-weight ratio, corrosion resistance, and fatigue resistance required for these demanding applications. Furthermore, steel billets can be used to produce landing gear components in the aerospace aftermarket. Landing gear plays a critical role in the safe operation of an aircraft, and it must withstand significant loads and stresses during takeoff, landing, and taxiing. Steel billets can be machined into landing gear parts such as axles, struts, and wheels, which require high strength, toughness, and fatigue resistance. Lastly, steel billets find applications in the production of fasteners used in the aerospace aftermarket. Fasteners such as bolts, screws, and nuts are essential for joining various components together in an aircraft. Steel billets can be forged or machined into high-strength fasteners that can withstand the high loads and vibrations experienced during flight. In summary, steel billets have numerous potential applications in the aerospace aftermarket. From engine parts to airframe structures, landing gear components, and fasteners, steel billets provide the necessary properties required for the demanding aerospace industry, including strength, durability, temperature resistance, and fatigue resistance.

Send your message to us

Steel Billet Manufacturers Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords