Steel Square Billets for construction Q195 and Q235 Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

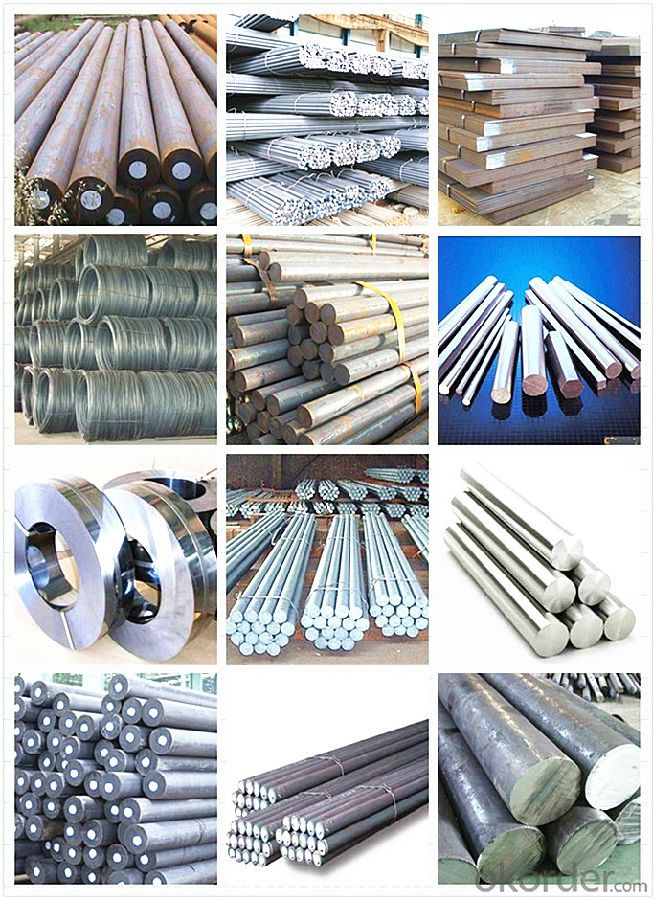

You Might Also Like

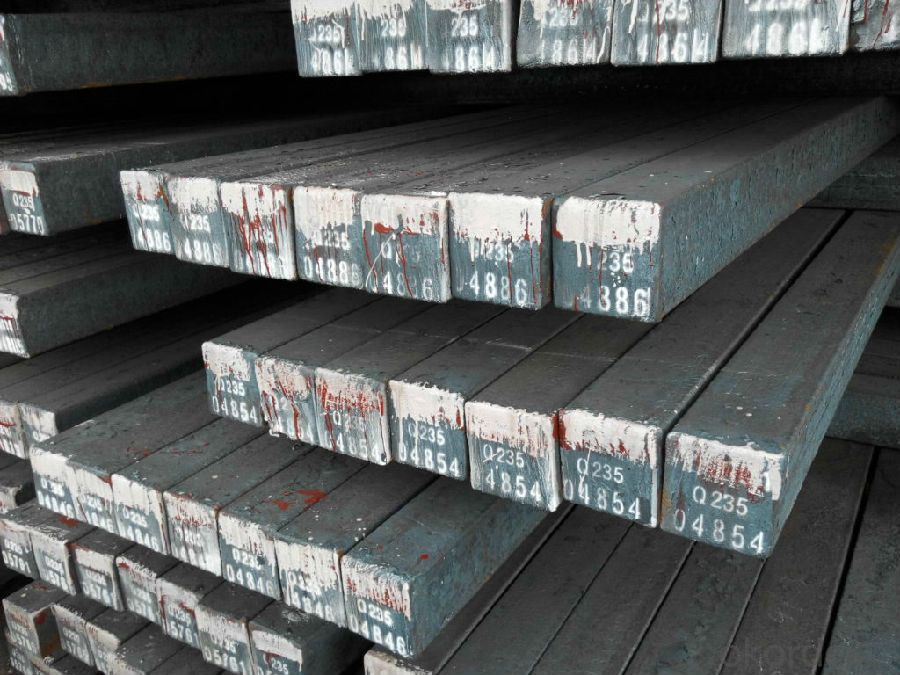

Product Description of Steel Square Billets for construction Q195 and Q235 Materials

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Steel Square Billets for construction Q195 and Q235 Materials

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Steel Square Billets for construction Q195 and Q235 Materials

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Steel Square Billets for construction Q195 and Q235 Materials

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can steel billets be used for marine applications?

- Indeed, the utilization of steel billets in marine applications is possible. Frequently, steel billets serve as a fundamental resource for diverse marine components and structures. Given their remarkable strength and durability, steel billets are ideal for marine applications necessitating resistance to corrosion, impact, and harsh environmental conditions. Ship hulls, propeller shafts, marine pipelines, offshore platforms, and other marine structures can all be manufactured using steel billets. Moreover, steel billets can undergo additional processing and shaping to meet precise specifications for marine applications.

- Q: How are steel billets used in the manufacturing of construction machinery parts?

- Steel billets are an essential component in the manufacturing of construction machinery parts. These billets, which are semi-finished steel products, serve as the raw material from which various machinery components are formed. To start the manufacturing process, steel billets are first heated to a high temperature in a furnace, which helps to increase their malleability and facilitate further shaping. Once heated, the billets are then passed through a series of rollers and molds to form the desired shape and dimensions. Construction machinery parts such as gears, shafts, axles, and structural components require high strength and durability to withstand the rigorous demands of heavy-duty applications. Steel billets, being made from high-quality steel alloys, possess these desirable properties, making them ideal for manufacturing such parts. After the billets have been shaped, they undergo additional processes such as heat treatment and surface finishing to enhance their strength, hardness, and resistance to wear and corrosion. These treatments further improve the overall performance and longevity of the construction machinery parts. The use of steel billets in the manufacturing of construction machinery parts offers several advantages. Firstly, steel is known for its excellent mechanical properties, including high tensile strength and toughness, which are crucial for handling heavy loads and resisting impact and fatigue. Additionally, steel billets can be easily machined and welded, allowing for precise manufacturing and assembly of complex machinery components. Furthermore, steel is a versatile material that can be customized to meet specific requirements. By adjusting the composition and heat treatment processes, manufacturers can tailor the properties of the steel billets to suit the intended application of the construction machinery parts, ensuring optimal performance and durability. In conclusion, steel billets play a vital role in the manufacturing of construction machinery parts. Their high strength, durability, and versatility make them indispensable in producing components that can withstand the demanding conditions of construction sites. By utilizing steel billets, manufacturers can create reliable and long-lasting machinery parts that contribute to the overall efficiency and safety of construction projects.

- Q: Can steel billets be used in the production of appliances?

- Yes, steel billets can be used in the production of appliances. Steel billets are semi-finished products that are typically used for further processing into various shapes and sizes. In the case of appliances, steel billets can be used as the raw material for manufacturing components such as frames, panels, and other structural parts. Steel is a versatile and durable material that offers strength, stability, and resistance to corrosion, making it suitable for use in appliances that require robust construction. Additionally, steel can be easily molded and shaped to meet the specific design requirements of different appliances, making it a preferred choice in the manufacturing process.

- Q: What are the potential risks associated with steel billet production?

- There are several potential risks associated with steel billet production. One significant risk is the high temperature involved in the process, which can lead to burns and fire hazards if not properly managed. Additionally, the handling of heavy machinery and equipment poses a risk of accidents and injuries to workers. The use of chemicals and hazardous substances in the production process can also pose health risks if not handled safely. Another potential risk is the emission of pollutants and greenhouse gases during production, contributing to environmental concerns. It is crucial for steel billet producers to implement appropriate safety measures, train their employees, and adhere to environmental regulations to mitigate these risks.

- Q: What are the different surface finishes available for steel billets?

- There are several different surface finishes available for steel billets, depending on the specific requirements and applications. Some of the commonly used surface finishes include: 1. Hot Rolled: This is the most basic surface finish obtained by rolling the steel billets at high temperatures. It results in a rough and scaled surface, which is suitable for applications where aesthetics are not a concern. 2. Cold Rolled: In this process, the steel billets are rolled at room temperature to achieve a smoother and more polished surface finish. Cold rolling helps to improve the dimensional accuracy and surface quality of the billets. 3. Pickled and Oiled: This surface finish involves the removal of scale and rust from the steel billets by using an acid solution, followed by an oil coating to prevent corrosion. It provides a clean and rust-free surface, commonly used in the automotive and construction industries. 4. Galvanized: Galvanizing involves the application of a zinc coating to the steel billets to protect them from corrosion. This surface finish provides excellent corrosion resistance, making it suitable for outdoor applications, such as fencing, roofing, and structural components. 5. Passivated: Passivation is a chemical process that removes free iron from the steel surface, enhancing its corrosion resistance. This surface finish is commonly used in the production of stainless steel billets to improve their resistance to rust and other forms of corrosion. 6. Shot Blasting: Shot blasting involves the projection of small abrasive particles onto the steel billets' surface to remove scale, rust, and other impurities. This process results in a textured and uniform surface finish, ideal for applications where improved adhesion is required, such as painting or coating. 7. Polished: Polishing is a mechanical process that involves the use of abrasive materials to smoothen the surface of steel billets and achieve a high-gloss finish. This surface finish is often used in decorative applications, such as furniture, architectural components, and jewelry. It is important to note that the choice of surface finish for steel billets depends on various factors, including the intended application, desired aesthetics, and the level of corrosion resistance required.

- Q: How many tons of billets does it take to produce a ton of thread steel?

- The yield was increased, consumption will be reduced.

- Q: What is the role of steel billets in the manufacturing of railway wheels?

- Steel billets play a crucial role in the manufacturing of railway wheels. They serve as the primary raw material used to create these wheels. Railway wheels need to be extremely strong, durable, and able to withstand heavy loads, extreme temperatures, and constant wear and tear. Steel billets are first melted down and then shaped into a cylindrical form, which is similar to the final shape of the railway wheel. These billets are then further processed through a series of manufacturing steps, such as hot rolling, forging, and machining, to transform them into the desired shape and dimensions of the railway wheel. The main advantage of using steel billets is their high strength and toughness. Steel is renowned for its excellent mechanical properties, including high tensile strength and hardness. These characteristics are essential for railway wheels, as they need to bear enormous loads and resist deformation under extreme pressures. Moreover, steel billets provide the necessary metallurgical properties required for railway wheels. They can be alloyed with additional elements such as carbon, manganese, and chromium to enhance their strength, hardness, and resistance to corrosion and fatigue. This ensures that the railway wheels maintain their structural integrity and performance over an extended period of time. In summary, steel billets are the starting point in the manufacturing process of railway wheels. They provide the raw material necessary to create robust, durable, and reliable wheels that can withstand the demanding conditions of railway operations. The use of steel billets ensures that railway wheels meet the stringent requirements for safety, performance, and longevity in the transportation industry.

- Q: What does the billet of the steel plant refer to?And steel what is the difference?

- Many species, usually by chemical composition, production process, rolling shape, supply form, diameter, and use in the structure the classification of steel bars for concrete reinforcement refers to straight or strip steel plate reinforced concrete reinforcement steel, its shape is divided into round steel bar and deformed steel two. Steel bars in concrete under tensile stress.

- Q: What are the different types of steel billet forging machines?

- Today in the market, one can find various steel billet forging machines. These machines are designed to efficiently shape and form steel billets into desired sizes and shapes. Below are some commonly used types: 1. Hydraulic Forging Press: These machines utilize hydraulic power to exert force on the steel billet, allowing it to be forged into the desired shape. Known for their versatility and high force capabilities, hydraulic forging presses can handle different sizes of billets. 2. Mechanical Forging Press: These machines rely on mechanical power, such as flywheels or eccentric mechanisms, to apply force to the billet. They are known for their precision and reliability, making them suitable for high-volume production. 3. Screw Press: Screw presses make use of a rotating screw mechanism to apply force to the steel billet. They operate at high speeds and are energy-efficient. Screw presses are commonly used for forging small to medium-sized billets. 4. Hammer Forging Machine: This type of machine uses a hammering action to shape the steel billet. There are different types of hammer forging machines, including steam hammers, air hammers, and hydraulic hammers. Due to their high impact force, they are ideal for heavy-duty forging. 5. Upsetter: Upsetters, also known as upsetting machines, are specifically designed for forging the ends of steel billets. They use a vertical or horizontal ram to apply pressure, causing the billet to increase in diameter and length. Upsetters are commonly used for producing forged components with thickened ends. 6. Radial Forging Machine: Radial forging machines employ a rotating roller to apply radial force to the steel billet. This force increases the diameter of the billet while maintaining its original length. Radial forging machines are often used for producing seamless rings and other cylindrical components. It is important to consider factors such as billet size and shape, desired production volume, and specific product requirements when selecting the most suitable steel billet forging machine. Each type of machine has its own advantages and limitations, so careful consideration is necessary for the best choice.

- Q: What are the main challenges in the handling of steel billets during production?

- The handling of steel billets during production presents several challenges that need to be overcome for a smooth and efficient manufacturing process. One of the main challenges is the weight and size of the steel billets. Steel billets can be quite heavy, ranging from a few hundred kilograms to several tons, depending on their dimensions. This poses difficulties in terms of lifting and moving them within the production facility. Specialized equipment such as cranes and forklifts are required to handle these heavy loads safely. Another challenge is the potential for damage to the steel billets during handling. Steel billets are typically transported and stored in stacks or bundles. Improper handling techniques or insufficient protection can lead to deformation, scratches, or even breakage of the billets. These damages can affect the quality of the final product, leading to increased scrap rates and production costs. Additionally, maintaining precise temperature control is crucial during the handling of steel billets. Steel is sensitive to temperature changes, and the billets need to be kept within specific temperature ranges to avoid distortion or metallurgical issues. Special care must be taken when transferring billets between different areas of the production facility to ensure temperature consistency. Ensuring proper inventory management and tracking is also a challenge in billet handling. Steel billets are often stored in large warehouses or outdoor yards, and keeping track of their location, quantity, and quality can be complex. Efficient inventory management systems, such as barcoding or RFID tagging, are essential to minimize errors and efficiently retrieve the required billets for production. Lastly, safety is a significant concern when handling steel billets. The weight and potential for injury make it vital to follow strict safety protocols. Operators need to be properly trained on the use of equipment, such as cranes and forklifts, and wear appropriate personal protective equipment (PPE) to prevent accidents or injuries. Overall, the main challenges in the handling of steel billets during production revolve around their weight, potential for damage, temperature control, inventory management, and safety. Overcoming these challenges requires investments in specialized equipment, training, and efficient processes to ensure a smooth and successful production operation.

Send your message to us

Steel Square Billets for construction Q195 and Q235 Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords