Steel Billets 5sp Grade Q235 Q275 Q345 Brand New Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billets 5sp Grade Q235 Q275 Q345 Brand New Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

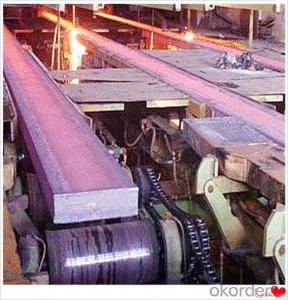

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

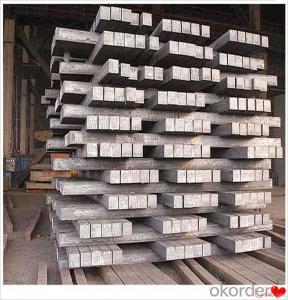

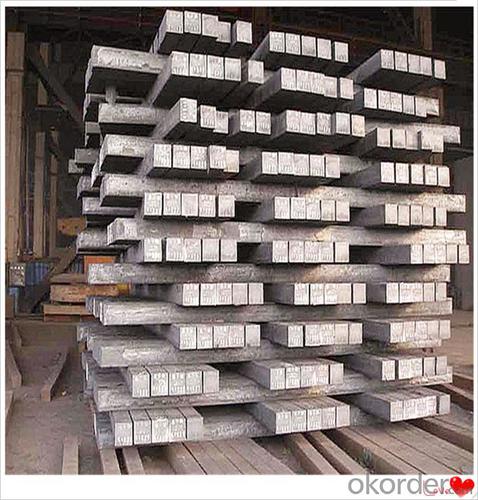

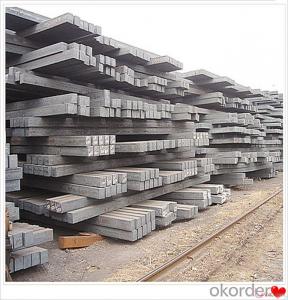

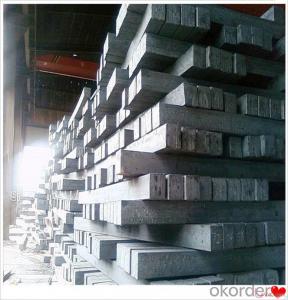

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets used in the production of conveyor systems?

- Steel billets are used in the production of conveyor systems as the raw material for manufacturing various components, such as frames, supports, rollers, and pulleys. These billets are typically shaped, cut, and machined into the required sizes and shapes to ensure the strength and durability of the conveyor system.

- Q: How do steel billets contribute to the manufacturing of rail and transportation systems?

- Steel billets are an essential component in the manufacturing of rail and transportation systems. These billets serve as the raw material for the production of various components used in the construction of railways, such as rails, sleepers, and fasteners. One of the primary uses of steel billets in rail manufacturing is for the production of railway tracks. Steel billets are first heated and then rolled into long, slender sections called rails. These rails are then further processed and treated to withstand the heavy loads and constant wear and tear experienced in railway operations. The durability, strength, and resistance to deformation of steel make it an ideal material for railway tracks, ensuring safe and efficient transportation. Steel billets also play a vital role in the manufacturing of sleepers or railroad ties, which are used to support the rails and maintain their alignment. These sleepers, typically made from prestressed concrete or wood, require reinforcing bars made from steel billets to enhance their strength and structural integrity. Additionally, steel billets are used to produce fasteners, such as bolts, clips, and spikes, which are crucial for securely fastening rails to sleepers and maintaining track stability. Moreover, steel billets are used in the production of various transportation system components, including chassis, frames, and suspension systems for trains, trams, buses, and other vehicles. Their high strength and excellent formability make steel billets an ideal choice for these applications, as they can withstand the heavy loads and provide structural integrity necessary for safe and reliable transportation. In summary, steel billets play a significant role in the manufacturing of rail and transportation systems. From the production of railway tracks to the fabrication of sleepers, fasteners, and vehicle components, steel billets provide the necessary strength, durability, and structural integrity required for the efficient and safe operation of railways and transportation systems.

- Q: What are the common sizes and dimensions of steel billets?

- Steel billets are semi-finished products that are typically produced through continuous casting or by hot rolling methods. The sizes and dimensions of steel billets can vary depending on the specific requirements of the industry and the intended use of the billets. However, there are some common sizes and dimensions that are widely utilized in various applications. The most common size range for steel billets is between 100mm and 150mm square. These billets usually have a length of around 6 meters, although this can also vary depending on the specific needs of the customer or the manufacturing process. Additionally, round steel billets are also commonly produced with diameters ranging from 100mm to 200mm. In terms of weight, steel billets can range from a few hundred kilograms to several metric tons. The weight of a billet is determined by its length, cross-sectional area, and the density of the steel used. The majority of steel billets fall within the range of 1 to 5 metric tons. It is important to note that these dimensions and sizes can vary from one manufacturer to another, and different industries may have specific requirements for their steel billets. For example, the automotive industry may require larger or smaller billets depending on the type of parts being produced. In conclusion, the common sizes and dimensions of steel billets are typically between 100mm and 150mm square, with lengths of around 6 meters. Round billets can have diameters ranging from 100mm to 200mm. The weight of a steel billet can vary from a few hundred kilograms to several metric tons. However, it is essential to consider that these measurements can vary depending on the industry and customer requirements.

- Q: How are steel billets inspected for chemical composition?

- Chemical analysis is utilized to inspect the chemical composition of steel billets. This involves extracting a sample from the billet and subjecting it to various testing methods in order to ascertain the precise quantities of different elements present in the steel. A commonly employed technique is spectrometry, specifically optical emission spectrometry (OES) or inductively coupled plasma (ICP) spectrometry. These methods entail heating the steel sample to a plasma state, allowing individual elements to emit distinct wavelengths of light. By analyzing the emitted light, the concentration of each element can be determined. Another approach is X-ray fluorescence (XRF) analysis. This method involves bombarding the steel sample with high-energy X-rays, prompting the atoms in the sample to emit secondary X-rays. By measuring the energy and intensity of these secondary X-rays, the steel's composition can be determined. Depending on the specific inspection requirements and necessary accuracy, additional techniques like mass spectrometry and wet chemical analysis may also be utilized. In summary, a combination of sophisticated analytical techniques is used to inspect the chemical composition of steel billets, ensuring that the steel adheres to desired specifications and quality standards.

- Q: How are steel billets stored to prevent corrosion?

- In order to prevent corrosion, steel billets are typically stored in a manner that avoids direct contact with moisture and oxygen, which are the primary culprits. One common approach involves keeping the billets indoors in a controlled environment, such as a warehouse or storage facility. These facilities are specially designed to maintain low levels of humidity and often feature climate control systems for temperature and moisture regulation. To provide further protection against corrosion, steel billets can be placed on wooden pallets or racks. This ensures that they are kept away from the ground and any potential sources of moisture. Additionally, it is customary to apply a protective coating or oil film on the surface of the billets before storing them. This coating acts as a barrier, preventing moisture and oxygen from directly contacting the steel and reducing the risk of corrosion. Regular inspections and maintenance are crucial to promptly identify and address any signs of corrosion. This may involve periodic cleaning, applying additional protective coatings, or implementing other preventive measures as needed. By storing steel billets in a controlled environment, applying protective coatings, and conducting regular inspections, the risk of corrosion can be significantly minimized. This ensures that the billets remain in optimal condition for future use.

- Q: Can steel billets be used in the production of jewelry?

- Steel billets are typically not used in the production of jewelry due to their composition and properties. Steel is an alloy primarily composed of iron and carbon, with additional elements such as manganese, chromium, and nickel. This composition gives steel its strength and durability, making it ideal for various industrial applications, but not for jewelry production. Jewelry is often crafted from precious metals like gold, silver, and platinum, which possess unique characteristics that make them suitable for adornment. These metals are malleable, meaning they can be easily shaped and molded into intricate designs. Additionally, they have a lustrous appearance and are resistant to tarnishing or corrosion. Steel, on the other hand, is much harder and less ductile compared to precious metals. It cannot be easily manipulated into delicate and intricate shapes required for jewelry making. Furthermore, steel has a dull gray color, which does not provide the desired aesthetic appeal in jewelry. While it is technically possible to create jewelry using steel billets, it is not a common practice due to the aforementioned reasons. Steel is primarily used in industries where its high strength and durability are necessary, such as construction, automotive, and machinery manufacturing.

- Q: Can the production of continuous casting billet be damaged by using intermediate frequency electric furnace?

- If there are no other major facts of harm, it seems that there is no such mandatory legal provisions to bear criminal responsibility. Mandatory closing and fines at most.

- Q: What is the difference between steel billets and steel bars?

- Steel billets and steel bars are both raw forms of steel, but they differ in terms of their shapes and sizes. Steel billets are larger, rectangular-shaped semi-finished products that are typically used as input material for further processing, such as rolling or forging. On the other hand, steel bars are smaller, cylindrical-shaped finished products that have undergone additional processing, such as hot or cold rolling, to achieve a desired shape and size. In summary, steel billets are the starting point in the steel production process, while steel bars are the end products ready for use in various applications.

- Q: How do steel billets contribute to the overall aesthetics of a product?

- Steel billets play a crucial role in enhancing the overall aesthetics of a product in several ways. Firstly, the quality and finish of steel billets greatly impact the appearance of the final product. Steel billets are often used as raw material for various manufacturing processes such as forging, rolling, or machining. The smooth surface and uniform shape of high-quality steel billets contribute to a sleek and refined look of the end product. Additionally, steel billets offer designers and manufacturers a wide range of possibilities in terms of shape and size. They can be easily customized and transformed into various forms, allowing for intricate and unique designs that enhance the visual appeal of the product. Steel billets can be molded, cut, or manipulated to create complex patterns, textures, or contours, offering endless opportunities for artistic expression. Moreover, the strength and durability of steel billets contribute to the longevity and resilience of the final product. Aesthetics are not only about visual appeal but also about the perception of quality. Steel billets, known for their robustness and resistance to corrosion, provide a sense of reliability and sturdiness. This perceived quality enhances the overall attractiveness of the product, making it more desirable to consumers. In summary, steel billets contribute to the overall aesthetics of a product by providing a high-quality, customizable, and durable raw material. Their smooth surface, versatility in shaping, and inherent strength enhance the visual appeal, allowing designers to create visually captivating and long-lasting products.

- Q: How do steel billets contribute to the overall safety of a structure?

- Steel billets contribute to the overall safety of a structure by providing a strong and durable material for construction. The high strength and toughness of steel billets make them resistant to external forces such as earthquakes, wind, and heavy loads. Additionally, steel billets have excellent fire resistance, as they do not burn or release toxic gases when exposed to high temperatures. This ensures the structural integrity of the building during a fire. Moreover, steel billets can be easily fabricated into various shapes and sizes, allowing for precise engineering and construction, which further enhances the safety and stability of the structure.

Send your message to us

Steel Billets 5sp Grade Q235 Q275 Q345 Brand New Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords