Steel billet for rebar steel material from china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 24983 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into

more functional shapes and sizes. While they have already been put in the furnace, they still require a series

of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in

hardware stores, or used for different applications. The unformed billets, however, can be used in striking

currency such as coins and as reserves, similar to gold bars.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the

support foundation pile manufacturing.

Qaulity:own factory, stable quality

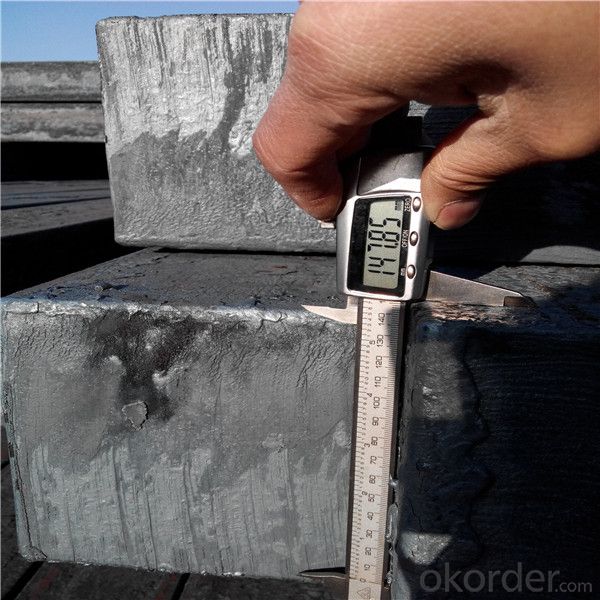

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets used in the manufacturing of industrial machinery?

- Steel billets are used in the manufacturing of industrial machinery as raw materials that are shaped and processed into various components, such as gears, shafts, and frames. These billets are heated, forged, and machined to create the desired shapes and sizes, providing the necessary strength and durability for the machinery to function effectively in various applications.

- Q: How do steel billets compare to other metal billets?

- Steel billets are frequently regarded as superior to other metal billets because of their distinctive properties and characteristics. One of the primary advantages of steel billets is their exceptional strength and durability. With a high tensile strength, steel is resistant to deformation and can withstand heavy loads and stresses. Furthermore, steel billets exhibit excellent thermal conductivity, enabling efficient heat transfer. This characteristic proves particularly advantageous in industries like construction and automotive, where effective heat dissipation is vital for optimal performance and longevity of the final product. Steel billets also boast a high melting point, enabling them to endure extreme temperatures without compromising their structural integrity. This makes them suitable for applications involving exposure to high heat, such as in furnaces or engines. Moreover, steel billets possess the ability to be easily formed and shaped into various sizes and dimensions, rendering them highly versatile for a wide array of applications. They can be rolled, forged, or extruded, allowing manufacturers to create diverse products tailored to specific requirements. Furthermore, steel billets possess excellent corrosion resistance, particularly when combined with protective coatings or treatments. This makes them ideal for outdoor applications or environments where they may come into contact with moisture or chemical substances. In terms of cost-effectiveness, steel billets are often more economical compared to other metal billets like aluminum or titanium. This is due to the abundant availability of iron ore, the primary component of steel, and the efficiency of steel production processes. In conclusion, steel billets possess a unique combination of strength, durability, thermal conductivity, versatility, and cost-effectiveness that distinguishes them from other metal billets. These qualities make steel billets highly sought after in a broad range of industries, including construction, automotive, manufacturing, and infrastructure development.

- Q: What are the main factors affecting the metallurgical properties of steel billets?

- The main factors affecting the metallurgical properties of steel billets include the chemical composition of the steel, the cooling rate during solidification, the presence of impurities or alloying elements, the microstructure, and the heat treatment processes applied.

- Q: What are the different methods of steel billet surface grinding?

- There are several methods of steel billet surface grinding, including abrasive grinding, belt grinding, and centerless grinding.

- Q: What are the different heat treatment processes used for steel billets?

- Steel billets undergo various heat treatment processes, each with its own distinct purpose and resulting in different mechanical properties. These processes encompass annealing, normalizing, quenching, tempering, and case hardening. Annealing involves heating the steel billets to a specific temperature and gradually cooling them to enhance ductility and soften the material. This process mitigates internal stresses and promotes uniformity in the steel's microstructure. Normalizing entails heating the steel billets beyond the critical point and allowing them to cool in ambient air. This process improves the grain structure and mechanical properties like strength and toughness. It also reduces residual stresses and enhances the steel's machinability. Quenching is a rapid cooling technique that immerses heated steel billets in a quenching medium, such as water or oil, to achieve high hardness. The resulting material is brittle, necessitating subsequent tempering to reduce brittleness and improve toughness. Tempering involves reheating quenched steel billets to a specific temperature and then allowing them to cool slowly. This process relieves residual stresses and enhances material toughness and ductility. It also reduces the hardness attained during quenching, resulting in a balanced combination of strength and toughness. Case hardening selectively hardens the surface layer of steel billets while maintaining a softer and more ductile core. This is accomplished by introducing carbon or nitrogen into the material's surface layer through carburizing or nitriding processes. Case hardening improves surface hardness and wear resistance, making it suitable for applications that require high surface hardness. Overall, these diverse heat treatment processes for steel billets yield a range of mechanical properties, enabling customization based on specific application requirements. Each process possesses unique advantages and limitations, with selection dependent on factors such as desired mechanical properties, steel grade, and intended application.

- Q: How do steel billets contribute to the overall weight reduction of a structure?

- Steel billets contribute to the overall weight reduction of a structure by being a lightweight and high-strength material. They allow for the design of thinner and more efficient structural elements, reducing the amount of steel required, and consequently the weight of the structure.

- Q: What is the role of steel billets in the manufacturing of construction machinery?

- Steel billets play a crucial role in the manufacturing of construction machinery due to their exceptional strength and durability. These billets, which are semi-finished products made from molten steel, are shaped into various forms such as bars, rods, or sheets, depending on the specific machinery being produced. One of the primary reasons steel billets are used in the construction machinery industry is their ability to withstand heavy loads and extreme conditions. Construction machinery, such as excavators, bulldozers, cranes, and loaders, are subjected to intense stress and pressure during operation. Steel billets, being made from high-quality steel, provide the necessary structural integrity and resistance to deformation, ensuring the machinery can handle demanding tasks without compromising safety or performance. Additionally, steel billets offer excellent weldability, which is crucial in the construction machinery manufacturing process. Welding is often required to join different components together, and the use of steel billets ensures strong and reliable welds, contributing to the overall stability and longevity of the machinery. Moreover, steel billets can be easily machined and formed into complex shapes, allowing for the production of intricate parts and components required for construction machinery. This versatility enables manufacturers to design and fabricate machinery with precise specifications, enhancing their functionality and efficiency on the job site. Furthermore, steel billets are known for their resistance to corrosion and rust, making them ideal for construction machinery that is frequently exposed to harsh environmental conditions, including moisture, chemicals, and abrasive materials. This resistance ensures the longevity of the machinery, reducing maintenance costs and downtime. In summary, steel billets are indispensable in the manufacturing of construction machinery due to their strength, weldability, machinability, and resistance to corrosion. By incorporating steel billets into the production process, manufacturers can create robust and reliable machinery that can withstand heavy loads, extreme conditions, and perform efficiently in the construction industry.

- Q: What are the different grades of steel used for making billets?

- There are several different grades of steel that are commonly used for making billets. The specific grade of steel used depends on the intended application and the desired properties of the billet. One commonly used grade of steel for making billets is carbon steel. Carbon steel is a versatile and relatively inexpensive option that offers good strength and hardness. It is often used in applications where high strength is required, such as in the construction industry. Another grade of steel commonly used for billet production is alloy steel. Alloy steel is made by adding various alloying elements to carbon steel, such as chromium, nickel, or molybdenum. This results in improved strength, toughness, and corrosion resistance, making alloy steel suitable for a wide range of applications including automotive parts, machinery components, and tooling. Stainless steel is another grade of steel that is often used for making billets. Stainless steel contains a minimum of 10.5% chromium, which provides excellent corrosion resistance. It is commonly used in industries requiring resistance to oxidation and corrosion, such as the food and beverage industry, medical equipment manufacturing, and architectural applications. Additionally, there are specialized grades of steel used for specific applications. For example, high-speed steel (HSS) is used for making billets used in cutting tools, as it offers exceptional hardness and heat resistance. Tool steel is another specialized grade used for making billets for tools and dies, offering high hardness, wear resistance, and toughness. In summary, the different grades of steel used for making billets include carbon steel, alloy steel, stainless steel, high-speed steel, and tool steel. The choice of grade depends on the specific requirements of the application, such as strength, toughness, corrosion resistance, or specialized properties needed for cutting tools or tooling.

- Q: How are steel billets tested for mechanical properties?

- Steel billets are tested for mechanical properties using various methods to ensure their quality and suitability for specific applications. One common method is the tensile test, which involves pulling a small sample from the billet and subjecting it to a gradually increasing tensile force until it fractures. This test helps determine important mechanical properties such as ultimate tensile strength, yield strength, and elongation. Another method used is the hardness test, which measures the resistance of the billet's surface to indentation. This test provides information about the billet's hardness, which is crucial for assessing its ability to withstand wear and deformation. Additionally, the impact test is performed to evaluate the billet's toughness and ability to absorb energy. This involves striking a standardized sample with a pendulum and measuring the energy absorbed during fracture. The impact test is particularly important for applications where the steel billet is subjected to sudden loads or impacts. To assess the billet's ability to resist deformation, the compression test is employed. In this test, the billet is subjected to a compressive force until it deforms or fractures. The results obtained from this test help determine the billet's compressive strength and deformation characteristics. Furthermore, non-destructive testing methods such as ultrasonic testing and magnetic particle inspection are used to detect any internal defects or irregularities in the billet. These methods involve the use of specialized equipment to examine the billet's internal structure and identify any flaws that may compromise its mechanical properties. Overall, steel billets undergo a comprehensive range of tests to ensure their mechanical properties meet the required standards. These tests help guarantee the quality and reliability of the billets, enabling them to be used in various industries such as construction, automotive, and manufacturing.

- Q: How many tons of billets does it take to produce a ton of thread steel?

- Domestic steel manufacturers, production rate of about 97%, so probably need 1/97%=1.03 tons.

Send your message to us

Steel billet for rebar steel material from china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 24983 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords