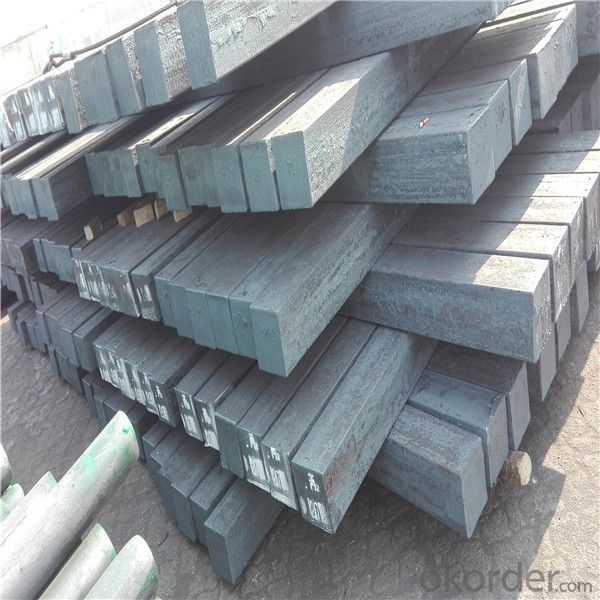

Mild steel billet for sale low price made in china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15542 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet :

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the different types of defects that can occur during casting of steel billets?

- There are several types of defects that can occur during the casting of steel billets. These include shrinkage cavities, porosity, cracks, inclusions, surface irregularities, and segregation. Shrinkage cavities occur due to the solidification process and can result in voids or cavities in the billet. Porosity refers to the presence of gas or air pockets within the billet, which can weaken its structure. Cracks can occur due to thermal stresses or improper cooling, leading to structural weaknesses. Inclusions are foreign materials such as oxides or non-metallic particles that can be trapped within the billet, impacting its quality. Surface irregularities refer to imperfections on the surface of the billet, which can affect its appearance and structural integrity. Segregation is the uneven distribution of alloying elements within the steel billet, leading to variations in the material's properties. These defects can impact the overall quality and performance of the finished steel product.

- Q: What is the role of steel billets in the construction of bridges and tunnels?

- Steel billets play a crucial role in the construction of bridges and tunnels as they serve as the raw material for manufacturing various structural elements. These billets are heated and shaped into beams, girders, and columns that provide the necessary strength and support required for these infrastructure projects. By using steel billets, engineers can ensure the durability, load-bearing capacity, and overall structural integrity of bridges and tunnels, making them safer and more reliable for transportation and other purposes.

- Q: What is the typical production process for steel billets?

- The process of producing steel billets typically involves a series of steps. Initially, raw materials like iron ore, coal, and limestone are acquired. These materials are then processed and converted into iron through a blast furnace or direct reduction method. To eliminate impurities and adjust the composition, the iron is further refined in either a basic oxygen furnace or an electric arc furnace. Once the iron has been refined, it is poured into large rectangular molds known as ingots. These ingots are subsequently heated and rolled into semi-finished products called blooms or slabs. Blooms usually have a square or rectangular shape, whereas slabs are flat and rectangular in form. The next stage is to further process the blooms or slabs into billets. This is achieved by reheating the semi-finished products and passing them through a sequence of rolling mills. The rolling mills exert pressure to shape the metal and decrease its thickness. This process, known as hot rolling, takes place. After hot rolling, the billets are cooled and carefully examined for any defects. They may also undergo additional processes, such as surface treatment or heat treatment, to enhance their properties. Finally, the billets are typically cut into desired lengths and stored before undergoing further processing or being shipped to customers. In conclusion, the production of steel billets involves obtaining raw materials, refining the iron, casting it into semi-finished products, hot rolling, and conducting final inspection and processing. This comprehensive process ensures that the steel billets meet the necessary specifications and quality standards before being utilized in various industries, including construction, automotive, and manufacturing.

- Q: What are the main factors affecting the hardenability of alloy steel billets?

- The main factors affecting the hardenability of alloy steel billets include the chemical composition of the alloy, the grain size and distribution, the cooling rate during heat treatment, and the presence of alloying elements such as carbon, manganese, chromium, and molybdenum. These factors determine the ability of the steel to form and retain a hardened structure, thus affecting its overall hardness and strength properties.

- Q: Charcoal classification

- Hard charcoal. By hardwood such as Fagaceae Quercus, Castanopsis trees, secondary birch and etc..Broad-leaved charcoal. Charcoal made from a mixture of hard and soft hardwood.Pine charcoal. Carbon fired from pine or other needle wood. In addition to bamboo and bamboo charcoal burning with shells, stones (coconut shell, peach stone charcoal etc.) wood raw material firing. Charcoal collected from household stoves in the cell known as carbon. If the charcoal is crushed and mixed with proper adhesive, and then pressed, formed and roasted, the deposit is made. According to the burning process of silica and carbon black.

- Q: How do steel billets contribute to the manufacturing of HVAC systems?

- Steel billets play a crucial role in the manufacturing of HVAC (Heating, Ventilation, and Air Conditioning) systems. These systems require robust and durable components to ensure efficient operation and longevity, and steel billets provide the necessary foundation for such components. Firstly, steel billets are used to create the main structural framework of HVAC systems. The framework, often referred to as the casing or housing, provides support and protection for the internal components, such as the heat exchangers, fans, and coils. Steel billets offer high strength and rigidity, making them ideal for creating a sturdy and reliable framework that can withstand the various stresses and strains encountered during the system's operation. Moreover, steel billets are also used to manufacture various internal components of HVAC systems. For example, the heat exchangers, which are responsible for transferring heat between the air and the refrigerant, are commonly made from steel billets. The high thermal conductivity and corrosion resistance of steel make it an excellent choice for these critical components, ensuring efficient heat transfer and long-term performance. Additionally, steel billets are utilized in the production of ductwork. Ductwork is the network of pipes or channels that distribute conditioned air throughout a building. Steel billets are often rolled and formed into the required shapes to create the ducts. The strength and durability of steel ensure that the ductwork can withstand the pressure differentials and mechanical stresses associated with air movement, maintaining the integrity of the system and preventing leaks. Furthermore, steel billets are essential for manufacturing HVAC system supports and brackets. These components are used to mount various equipment, such as air handling units or condensing units, securely. Steel's strength and load-bearing capacity make it an ideal material for ensuring the stability and proper installation of these crucial elements. In conclusion, steel billets are integral to the manufacturing of HVAC systems. They provide the necessary strength, durability, and thermal properties required for the structural framework, internal components, ductwork, and supports. Without steel billets, it would be challenging to produce HVAC systems that deliver efficient heating, ventilation, and air conditioning to buildings.

- Q: What is the composition of steel billets?

- Steel billets are solid, semi-finished products that are typically rectangular in shape and are used as raw material in the production of various steel products. The composition of steel billets can vary depending on the specific grade and type of steel being produced. However, in general, steel billets are primarily made up of iron and carbon, with trace amounts of other elements. The main component of steel billets is iron, which typically makes up the majority of the composition. Iron provides the structural strength and durability to the steel. Carbon is another important element present in steel billets, as it enhances the hardness and strength of the steel. The amount of carbon present in the billets determines the type of steel being produced, such as low carbon steel, medium carbon steel, or high carbon steel. In addition to iron and carbon, steel billets also contain small amounts of other elements. These elements may include manganese, silicon, sulfur, phosphorus, and various alloying elements such as chromium, nickel, and molybdenum. These trace elements are added to steel billets to improve specific properties, such as corrosion resistance, toughness, and heat resistance. It is important to note that the composition of steel billets can vary significantly depending on the intended application and specific requirements. Different industries and manufacturers may have their own proprietary blends or specifications for steel billets. Therefore, it is crucial to consult the appropriate standards and specifications to determine the precise composition of steel billets for a given application.

- Q: How are steel billets used in the production of crankshafts?

- Steel billets are an essential component in the production of crankshafts. A crankshaft is a vital part of an engine that converts the reciprocating motion of the pistons into rotational motion, thus providing power to the vehicle or machinery. The manufacturing process of crankshafts involves several steps, and steel billets play a crucial role in forming the base material for this intricate component. A steel billet is a semi-finished product, typically in a square or rectangular shape, which is obtained through the continuous casting or rolling of molten steel. To produce a crankshaft, the steel billet is first heated to a specific temperature, usually through induction heating, to enhance its malleability and make it easier to shape. The heated billet is then placed into a forging machine, where it undergoes a series of compressive forces and plastic deformation to gradually form the desired shape of the crankshaft. During the forging process, the steel billet is subjected to immense pressure to ensure that the metal grain structure aligns in the optimal direction, resulting in a stronger and more durable crankshaft. The precise shaping of the crankshaft's main bearing journals, crankpin journals, and counterweights is achieved through carefully controlled forging techniques. Once the forging process is complete, the partially finished crankshaft undergoes various machining operations, including milling, turning, and grinding, to refine its dimensions and surface finish. These operations help ensure the crankshaft meets the required specifications for smooth operation and efficient power transmission. In summary, steel billets serve as the raw material for crankshaft production. Through the forging process, the billet is shaped and transformed into a strong and resilient crankshaft that can withstand the demanding conditions of an engine. The use of steel billets helps produce crankshafts with superior strength, durability, and performance, making them a critical component in the automotive and machinery industries.

- Q: Can steel billets be used in the production of industrial equipment?

- Yes, steel billets can be used in the production of industrial equipment. Steel billets are semi-finished metal products that can be further processed to create various types of industrial equipment such as machinery, tools, automotive parts, construction materials, and more. The high strength, durability, and versatility of steel make it an ideal material for manufacturing industrial equipment. Steel billets can be shaped, machined, and welded to create complex structures and components, providing the necessary strength and stability required for industrial applications. Additionally, steel billets can be heat-treated to enhance their mechanical properties, making them even more suitable for use in heavy-duty industrial equipment.

- Q: What does the billet of the steel plant refer to?

- The steel billet is the continuous casting machine by smelting steel plant casting into the blank, in the middle of products before entering the rolling process, the section size will be decided by rolling steel.

Send your message to us

Mild steel billet for sale low price made in china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15542 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords