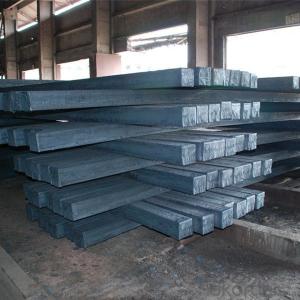

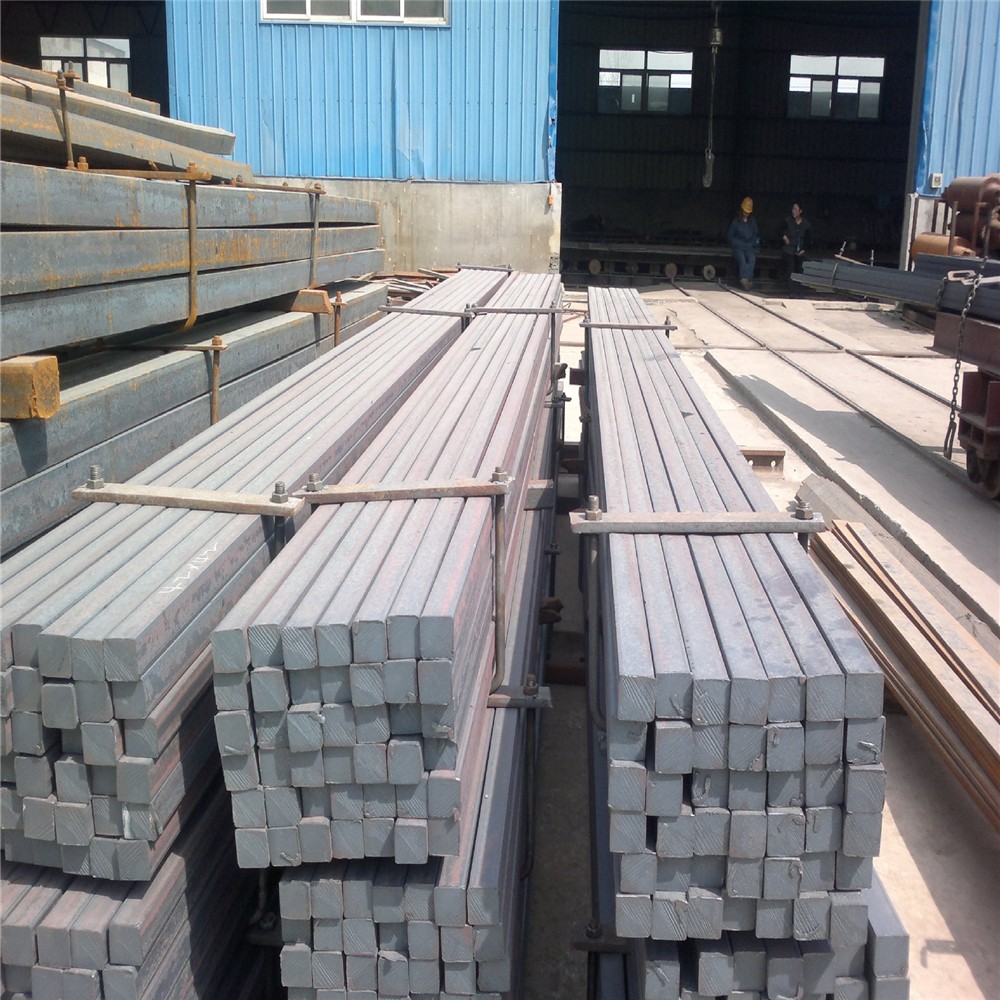

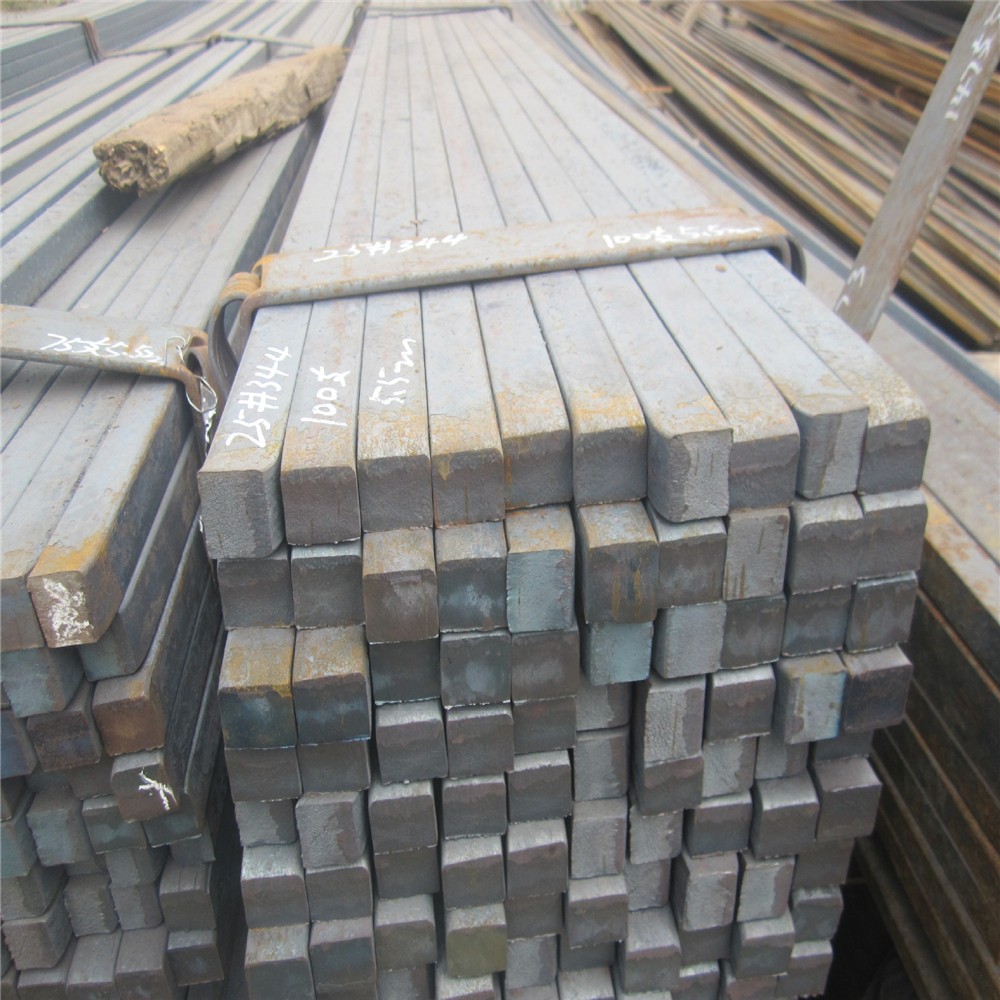

Square Steel Billets for Rolling Rebar From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

| Product Name | Steel Billets |

| Size | 60×60mm, 100×100mm, 120×120mm, 130×130mm, 150×150mm |

| Length | 6M, 9M, 12M |

| Grade | Q195, Q235, Q275, 3SP, 5SP, 20MnSi, Etc |

| Standard | ASTM, GB, JIS |

| Chemical Composition | Q235: C: 0.14-0.22% MN:0.3-0.7% SI: 0.3% max P:0.045%max S:0.045%max Q275 C: 0.27-0.38% MN:0.5-0.8% SI: 0.3% max P:0.045%max S:0.045%max |

| Delivery | 30-45days after L/C |

Pre-sale Service

1. Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3. OEM and ODM order are accepted, Any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

6. We have 8 year experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After you choose

1. We will count cheapest shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment,

3. Email you the tracking no, and help to chase the parcels until it arrive you.

After-sale choose

1. We are very glad that customer give us some suggestion for price and products.

2. If any question,please contact with us freely by E-mail or Telephone.

- Q: How do steel products contribute to the construction of hospitals and healthcare facilities?

- Steel products play a crucial role in the construction of hospitals and healthcare facilities. They are used in various applications, such as structural frameworks, support beams, and roofing systems. Steel's strength and durability ensure the safety and stability of these structures, making them capable of withstanding heavy loads and adverse weather conditions. Additionally, steel's versatility allows for flexible building designs and the incorporation of advanced technologies, such as medical equipment and electrical systems. Overall, steel products are essential in creating reliable, efficient, and modern healthcare facilities that can provide high-quality medical care to patients.

- Q: What are the properties of stainless steel for medical equipment?

- Stainless steel for medical equipment exhibits several key properties such as high corrosion resistance, excellent strength and durability, good heat resistance, and ease of sterilization. It is also non-reactive, biocompatible, and resistant to bacteria growth, making it a suitable material for surgical instruments, implants, and other medical devices.

- Q: How is steel used in the production of agricultural machinery?

- Steel is used in the production of agricultural machinery for its durability and strength. It is commonly used to construct the main frames, parts, and components of these machines, providing the necessary support and resistance to the heavy loads and harsh operating conditions commonly encountered in farming.

- Q: How are steel products used in the automotive industry?

- Steel products are widely used in the automotive industry for various applications, including the manufacturing of car bodies, frames, and structural components. Steel's high strength-to-weight ratio and durability make it an ideal material for ensuring the safety and structural integrity of vehicles. Additionally, steel is used in the production of engine parts, suspension systems, and exhaust systems due to its heat resistance and ability to withstand high temperatures.

- Q: How are steel products used in the mining industry?

- Steel products are widely used in the mining industry for various purposes such as constructing infrastructure, machinery, and equipment. Steel is used to build mine shafts, pipelines, buildings, and bridges, providing the necessary structural integrity and durability. Additionally, steel is employed in the fabrication of mining equipment like drill bits, crushers, and conveyor systems, which require robust materials to withstand the harsh conditions of mining operations. Overall, steel products play a vital role in supporting the mining industry's infrastructure and ensuring efficient and safe extraction processes.

- Q: What are the common uses of steel pipes and tubes?

- Steel pipes and tubes are commonly used in various industries and applications. They are extensively used for transporting fluids and gases, such as water, oil, and natural gas, in plumbing and gas distribution systems. Additionally, steel pipes and tubes are essential in construction projects for structural support, including building frames, bridges, and scaffolding. They are also used in the automotive industry for manufacturing exhaust systems and chassis components. Furthermore, steel pipes and tubes find applications in the manufacturing of furniture, appliances, and agricultural equipment. Overall, their durability, strength, and versatility make steel pipes and tubes indispensable in a wide range of sectors.

- Q: What are the uses of steel mesh in construction?

- Steel mesh is commonly used in construction for various purposes. It is primarily used as reinforcement in concrete structures to increase their tensile strength and prevent cracking. Steel mesh is also used in the construction of retaining walls, floor slabs, and foundations to provide added stability and resistance to external forces. Additionally, it is used in the fabrication of concrete pipes, culverts, and precast panels, as well as in the creation of fencing and barriers for safety and security purposes.

- Q: How are steel products used in the manufacturing of machinery?

- Steel products are used extensively in the manufacturing of machinery due to their strength, durability, and versatility. They are commonly used to construct machine frames, gears, shafts, and other components that require high strength and resistance to wear and tear. Additionally, steel is often utilized in the manufacturing of molds and dies, which are essential for shaping and forming various machine parts.

- Q: What are the different types of steel meshes and their applications?

- There are several types of steel meshes, each with its own unique characteristics and applications. 1. Welded Wire Mesh: This type of mesh consists of welded intersections, creating a rigid and strong structure. It is commonly used in construction projects for concrete reinforcement, fencing, and animal enclosures. 2. Expanded Metal Mesh: Made by cutting and stretching a metal sheet, this mesh has a diamond-shaped pattern. It is used in architectural applications, such as building facades, walkways, and filtration systems. 3. Woven Wire Mesh: Constructed through interlacing wires, this type of mesh is available in various patterns and sizes. It finds applications in industries like agriculture, mining, and filtration, where it is used for screening, sieving, and separating materials. 4. Perforated Metal Mesh: It is created by punching holes into a metal sheet, resulting in a pattern of regularly spaced openings. This mesh is widely used in industries like HVAC, automotive, and architecture for air ventilation, acoustic panels, and decorative purposes. 5. Wire Cloth: Composed of woven wires, wire cloth is used for a wide range of applications, including filtration, insect screening, and sieving. It is commonly found in industries such as food processing, chemical processing, and mining. These are just a few examples of steel meshes, and their applications are vast and diverse. The choice of mesh type depends on the specific requirements of the application, including strength, durability, aesthetics, and functionality.

- Q: What are the advantages of using steel in the construction of sports stadiums?

- There are several advantages of using steel in the construction of sports stadiums. Firstly, steel is a highly durable material, capable of withstanding heavy loads and extreme weather conditions. This ensures the long-term safety and structural integrity of the stadium. Secondly, steel offers great flexibility in design, allowing architects to create unique and innovative stadium structures. Additionally, steel is lightweight compared to other construction materials, which simplifies the construction process and reduces costs. Furthermore, steel is a sustainable and environmentally friendly choice, as it is often made from recycled materials and can be easily recycled at the end of its lifespan. Overall, these advantages make steel an ideal choice for constructing sports stadiums.

Send your message to us

Square Steel Billets for Rolling Rebar From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords