Steel Billets for Rebar Rolling Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Steel BilletsWe are one of steel manufacturer, our company specializes in manufacturing profile steel products such as H beams,I beams , Channel steel,and also can find some best quality angle steel,steel plate,steel pipe ,steel coils and many kinds of steel products of this kind.

Company Main Product Introduction:

Steel billet

Steel Profile:H-Beam/I-Beam/Equal Angle/Unequal Angle/U Channel /Flat Bar

Steel Plate:Hot Rolled Coil/Hot Rolled Checkered Coil/Cold Rolled Coil/Cutting Sheet

Wire Bar: Round Bar /Wire Rod/Deformed Bar

Steel Pipes: Seamless Pipe, Square/Round Pipes

Galvanized Steel: Angle/Channel/I-Beam/Round Bar/Flat Bar/Round-Square Pipe

Application:

Wire rod, deformed bars, rebar, profile steel, mechine parts and so on.

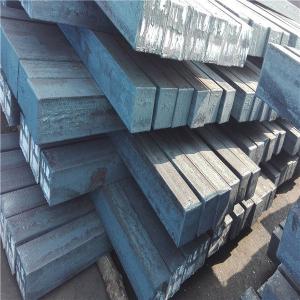

Proct Picture:

Specification:

| Type | Square, rectangular |

| Standard | GB, ASTM |

| Size | 60X60-150X150mm |

| Length | 6-12M or customised |

| Processing | Hot rolled continuous cast |

| Packing | Export standard packing |

Adventage:

1. Prime quality and competitive pirce

2. Good reputation and large market

3. Big company scale

4. Good service and prompt reply

Reasons for choosing us:

1. We have a large substantiality as our backup force. Our mill covers an area of 40000 square meters, has a modern standard workshop more than 19800 square meters. The existing staff of more than 180 people. The registered capital of twenty million yuan.

2. We have many qualified raw material supplier.

3. The company has perfect management mode and advanced processing technology.

4. We have the country's leading production equipment and strong production capacity.

5. Our company has a strong aftersales service platform, and our leaders are glad to make guidance personally for every feedback from customers.

6. Our company has a strong reputation system: SGS, ISO Certification, etc.

- Q: What are the different types of steel wire products?

- The different types of steel wire products include galvanized wire, stainless steel wire, spring wire, barbed wire, wire ropes, and wire mesh.

- Q: What are the factors to consider when selecting the appropriate steel grade for welding?

- When selecting the appropriate steel grade for welding, there are several factors to consider. These include the desired strength and hardness of the weld, the intended application or industry requirements, the welding process to be used, the base metal properties, the desired weldability and ease of fabrication, the availability and cost of the steel grade, and any specific requirements such as corrosion resistance or impact toughness. Additionally, factors such as the welding environment, the thickness of the base metal, and any post-weld heat treatment requirements should also be taken into account. Overall, a thorough evaluation of these factors will help ensure the selection of the most suitable steel grade for welding.

- Q: What are the uses of steel in the oil and gas industry?

- Steel is widely used in the oil and gas industry due to its exceptional strength, durability, and resistance to corrosion. It is primarily utilized for constructing pipelines, drilling equipment, and storage tanks. Steel pipes are used to transport crude oil, natural gas, and other fluids over long distances, ensuring safe and efficient delivery. Additionally, steel is employed in the fabrication of platforms, rigs, and subsea structures, providing a sturdy foundation for offshore drilling operations. Its versatility and reliability make steel an essential material in the oil and gas industry.

- Q: How is steel wire rope used in elevators?

- Steel wire rope is used in elevators as the primary means of supporting and moving the elevator car. It is an essential component of the elevator system, providing strength and stability. The wire rope is attached to the elevator car and loops over a traction sheave, which is connected to an electric motor. As the motor rotates the sheave, the wire rope moves, lifting or lowering the elevator car. The steel wire rope's high tensile strength and durability make it ideal for withstanding the heavy loads and constant use in elevator applications.

- Q: How is steel wire galvanized?

- Steel wire is galvanized by immersing it in a bath of molten zinc or by electroplating it with a layer of zinc. This process helps to protect the steel wire from corrosion and extends its lifespan.

- Q: What are the common welding techniques used for steel?

- The common welding techniques used for steel include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and gas tungsten arc welding (GTAW).

- Q: What are the different types of steel valves?

- There are several types of steel valves, including gate valves, globe valves, ball valves, check valves, butterfly valves, and needle valves. Each type has its own unique design and functionality, catering to specific applications and industries.

- Q: How is steel plate cut using CNC machines for fabrication?

- Steel plate is cut using CNC machines for fabrication by following a step-by-step process. First, a digital design or blueprint is created using computer-aided design (CAD) software. This design is then converted into a program that can be understood by the CNC machine. The steel plate is securely clamped onto the machine's work surface, and the cutting tool, typically a high-speed rotating cutter or laser, is positioned above the plate. The CNC machine then moves the cutting tool along the programmed path, precisely cutting the steel plate according to the design. The machine's computer-controlled accuracy ensures that the cuts are made with high precision and repeatability.

- Q: How are steel profiles used in the construction of underground tunnels?

- Steel profiles are commonly used in the construction of underground tunnels for structural support and stability. These profiles, typically in the form of beams or columns, are installed to reinforce the tunnel walls and prevent collapse. They provide strength and rigidity, helping to distribute the weight of the surrounding soil or rock and withstand external forces such as ground pressure. Additionally, steel profiles can be used to create the framework for tunnel formwork, allowing for the efficient casting of concrete walls or lining. Overall, steel profiles play a crucial role in ensuring the safety and durability of underground tunnels.

- Q: What are the applications of steel forgings in the oil and gas industry?

- Steel forgings have numerous applications in the oil and gas industry due to their exceptional strength, durability, and resistance to extreme conditions. They are commonly used in critical components such as valves, flanges, and fittings, ensuring reliable and leak-free operations. Additionally, steel forgings are essential for constructing offshore platforms, pipelines, and drilling equipment, where their high load-bearing capacity and resistance to corrosion are crucial. The industry relies on steel forgings to enhance safety, longevity, and overall efficiency in various operations.

Send your message to us

Steel Billets for Rebar Rolling Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords