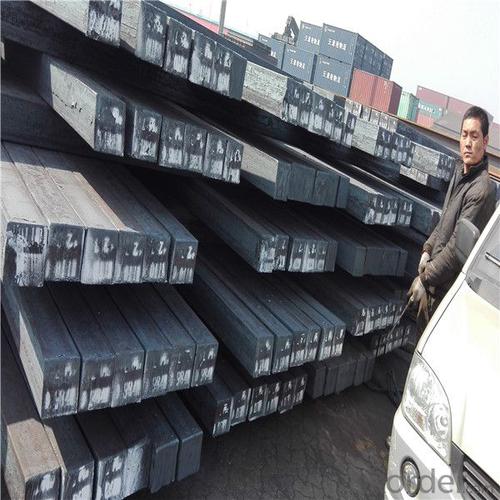

Steel billet price from China steel factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16532 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the

support foundation pile manufacturing.

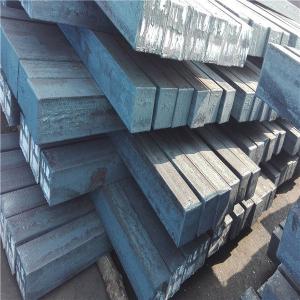

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How do steel billets contribute to the manufacturing of construction equipment?

- Steel billets contribute to the manufacturing of construction equipment by serving as the raw material that is shaped and formed into different components such as beams, plates, and pipes. These billets are heated and then passed through various processes like rolling, forging, and machining to create the desired shape and size. The strength, durability, and versatility of steel make it an ideal material for construction equipment, ensuring that the machinery can withstand heavy loads, harsh environments, and demanding construction tasks.

- Q: How are steel billets handled during transportation?

- To ensure the safety and integrity of steel billets during transportation, great care is typically taken. Specialized equipment, such as cranes, forklifts, or conveyors, is commonly used to lift and transport the heavy billets. Before being transported, the billets are often bundled or secured together to prevent shifting or falling. This bundling process may involve tightly holding the billets with steel straps or bands, ensuring they remain stable throughout transportation. Protective measures are also frequently implemented to prevent external damage. For example, the billets can be covered with protective coatings, such as oil or rust inhibitors, to shield them from moisture and corrosion. This is especially important when transporting billets over long distances or in unfavorable weather conditions. When it comes to loading the billets onto trucks, trains, or ships, careful attention is paid to balancing the weight distribution to avoid any imbalances or tipping during transit. The transportation vehicles used are designed to handle heavy loads and often have additional mechanisms, like straps, latches, or containers, to further secure the billets. During transit, the vehicles carrying the steel billets are operated with caution to minimize sudden movements or impacts. Drivers may need to follow specific routes or adhere to speed limits to ensure a smooth and safe journey. Regular inspections and maintenance of the transportation vehicles are carried out to ensure their reliability and prevent any mechanical failures that could jeopardize the safety of the billets. In conclusion, the transportation of steel billets requires meticulous planning, secure bundling, protective measures, and safe handling techniques. These practices are implemented to safeguard the billets and ensure they reach their destination in optimal condition, ready for further processing or utilization in various industries.

- Q: What is the difference between hot-rolled and cold-rolled steel billets?

- The main difference between hot-rolled and cold-rolled steel billets lies in the manufacturing process. Hot-rolled steel billets are formed by heating the steel to a high temperature and then rolling it while it is still hot, resulting in a rougher and less precise surface finish. On the other hand, cold-rolled steel billets are formed by cooling the steel and then rolling it at room temperature, which produces a smoother and more precise surface finish. This difference in manufacturing process also affects the mechanical properties of the steel, with hot-rolled steel generally having higher tensile strength but lower dimensional accuracy compared to cold-rolled steel.

- Q: What is the typical density of a steel billet?

- The density of a steel billet is contingent upon the particular type of steel employed. Nonetheless, in broad terms, the range of density for a steel billet falls between 7.75 and 8.05 grams per cubic centimeter (g/cm³). This density may exhibit slight fluctuations due to the steel's composition and quality. It is crucial to acknowledge that the presence of any impurities or contaminants in the material may additionally impact the density of a steel billet.

- Q: What are the main factors affecting the ductility of steel billets?

- There are several main factors that affect the ductility of steel billets. Firstly, one of the most significant factors is the carbon content in the steel. Higher carbon content generally reduces ductility and makes the steel more brittle. This is because carbon atoms tend to form strong bonds with iron atoms, resulting in a harder and less malleable material. Secondly, the composition of other alloying elements in the steel can also influence ductility. Elements such as manganese, silicon, and phosphorus can have different effects on the steel's ductility depending on their concentration. For example, manganese can enhance ductility while phosphorus can decrease it. Thirdly, the heat treatment process can have a significant impact on the ductility of steel billets. Rapid cooling, known as quenching, can increase the strength of the steel but may also reduce its ductility. On the other hand, annealing, which involves heating the steel and then slowly cooling it, can improve the ductility of the material. Additionally, the presence of impurities and defects in the steel can affect its ductility. Inclusions, such as non-metallic particles, can act as stress concentrators and reduce the material's ability to deform plastically. Similarly, cracks, voids, and other defects can also weaken the steel and decrease its ductility. Lastly, the grain size of the steel can influence its ductility. Fine-grained steels tend to have higher ductility compared to coarse-grained ones. This is because smaller grain boundaries provide more obstacles for dislocation movement, leading to increased resistance to deformation. Overall, the ductility of steel billets is influenced by various factors, including carbon content, alloying elements, heat treatment, impurities and defects, and grain size. Understanding and controlling these factors is essential for ensuring the desired ductility properties of steel.

- Q: What are the main factors that influence the strength of steel billets?

- The strength of steel billets is impacted by various factors, including the chemical composition, heat treatment, and microstructure of the steel. The chemical composition plays a significant role in determining the strength of steel billets. Alloying elements like carbon, manganese, silicon, and chromium can enhance strength by forming solid solutions or precipitates that increase hardness and tensile strength. It is crucial to control impurity levels and maintain the desired balance of alloying elements to achieve the desired strength properties. Heat treatment is another important factor that affects the strength of steel billets. This process involves heating the steel to a specific temperature and then cooling it at a controlled rate. It significantly impacts the microstructure of the steel, which ultimately influences its strength. For example, quenching and tempering can result in the formation of desired microstructures like martensite or bainite, which enhance strength and toughness. The microstructure of steel billets also plays a crucial role in determining their strength. The arrangement of crystal grains and the presence of different phases within the steel greatly influence its mechanical properties. Fine-grained structures generally exhibit higher strength due to a greater number of grain boundaries, which inhibit dislocation movement and enhance strength. Additionally, the presence of specific microstructural features like precipitates or second-phase particles can contribute to the strength of steel billets. Other factors such as the manufacturing process, cooling rate during solidification, and mechanical working (such as rolling or extrusion) can also affect the strength of steel billets. These factors impact grain size, grain boundary density, and defect concentration, all of which influence the mechanical properties of the steel. In conclusion, the strength of steel billets is influenced by the chemical composition, heat treatment, and microstructure of the steel. These factors can be carefully controlled and optimized to achieve the desired strength properties for various applications.

- Q: What are the main factors affecting the fatigue strength of alloy steel billets?

- The main factors affecting the fatigue strength of alloy steel billets include the composition of the alloy, the presence of impurities or defects, the heat treatment process, surface conditions, and the presence of residual stresses. Additionally, the applied load, frequency, and environmental conditions can also influence the fatigue strength of alloy steel billets.

- Q: Can steel billets be used in the production of industrial equipment?

- Yes, steel billets can be used in the production of industrial equipment. Steel billets are the raw material that can be further processed and shaped into various forms such as plates, sheets, rods, and bars. These processed steel products are commonly used in the manufacturing of industrial equipment due to their strength, durability, and suitability for machining and welding processes.

- Q: What industries use steel billets?

- Steel billets are widely used in various industries due to their strength, durability, and versatility. Some of the main industries that heavily rely on steel billets include construction, automotive, manufacturing, and energy. In the construction industry, steel billets are used for the production of structural components such as beams, columns, and girders. These components provide the necessary strength and support in buildings, bridges, and other infrastructure projects. The automotive industry utilizes steel billets for the manufacturing of various car parts, including engine components, chassis, and suspension systems. Steel billets are preferred in this industry due to their high strength-to-weight ratio, which improves fuel efficiency and overall performance. Manufacturing industries, such as machinery, equipment, and tool production, also heavily rely on steel billets. They are used to manufacture gears, shafts, valves, and other critical components that require high strength, durability, and precision. Furthermore, steel billets are essential in the energy sector, particularly in the production of oil and gas pipelines. These pipelines require steel billets of specific grades to withstand harsh conditions, high pressures, and corrosive environments. In addition to these main industries, steel billets find applications in other sectors such as shipbuilding, aerospace, mining, and agriculture. They are widely used wherever strength, durability, and reliability are crucial. Overall, steel billets have a diverse range of applications across various industries, thanks to their exceptional mechanical properties. The demand for steel billets remains strong, as they are an essential raw material in the production of critical components in numerous sectors.

- Q: How do steel billets contribute to the overall aesthetics of a product?

- Steel billets play a crucial role in enhancing the overall aesthetics of a product in several ways. Firstly, the quality and finish of steel billets greatly impact the appearance of the final product. Steel billets are often used as raw material for various manufacturing processes such as forging, rolling, or machining. The smooth surface and uniform shape of high-quality steel billets contribute to a sleek and refined look of the end product. Additionally, steel billets offer designers and manufacturers a wide range of possibilities in terms of shape and size. They can be easily customized and transformed into various forms, allowing for intricate and unique designs that enhance the visual appeal of the product. Steel billets can be molded, cut, or manipulated to create complex patterns, textures, or contours, offering endless opportunities for artistic expression. Moreover, the strength and durability of steel billets contribute to the longevity and resilience of the final product. Aesthetics are not only about visual appeal but also about the perception of quality. Steel billets, known for their robustness and resistance to corrosion, provide a sense of reliability and sturdiness. This perceived quality enhances the overall attractiveness of the product, making it more desirable to consumers. In summary, steel billets contribute to the overall aesthetics of a product by providing a high-quality, customizable, and durable raw material. Their smooth surface, versatility in shaping, and inherent strength enhance the visual appeal, allowing designers to create visually captivating and long-lasting products.

Send your message to us

Steel billet price from China steel factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16532 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords