Steel Angle Bar Middle Size

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Angle Bar Middle Size at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Angle Bar Middle Size are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Angle Bar Middle Size are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

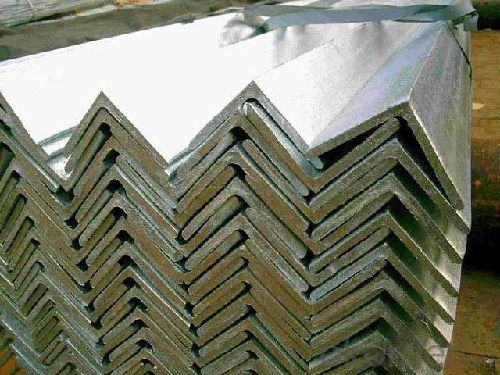

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: 316 stainless steel from drilling, can I do it?

- According to the characteristics and classification of steel, stainless steel, divided into resistance to nitric acid sulfuric acid resistant stainless steel, stainless steel, pitting corrosion resistance to stress corrosion of stainless steel, stainless steel and other steel; according to the classification features, divided into low temperature stainless steel, non-magnetic stainless steel, free cutting stainless steel, super plastic stainless steel etc.. At present, the commonly used classification methods are classified according to the characteristics of the steel structure, the chemical composition of steel and the combination of the two.

- Q: Can steel I-beams be used in mezzanine floors?

- Yes, steel I-beams can be used in mezzanine floors. Steel I-beams are commonly used in construction for their strength and load-bearing capabilities. Mezzanine floors are often added to existing structures to create additional space, and steel I-beams provide the necessary support for these elevated floors. The I-beams can be designed and engineered to meet the specific load requirements of the mezzanine floor, ensuring structural integrity and safety. Additionally, steel I-beams offer versatility in terms of design and can be customized to fit the unique requirements of the mezzanine floor, making them a popular choice for this type of construction.

- Q: How are steel I-beams installed on a construction site?

- Steel I-beams are installed on a construction site by first preparing the foundation or support structure. The beams are then lifted into place using cranes or other heavy machinery. They are carefully aligned and secured in position using bolts, welding, or a combination of both. Additional supports may be added as needed to ensure stability and structural integrity.

- Q: Can steel I-beams be painted or coated to match the desired aesthetics?

- Yes, steel I-beams can be painted or coated to match the desired aesthetics. Painting or coating the I-beams can provide a finished appearance, enhance their durability, and protect them from corrosion. This allows for customization and integration of the I-beams into various architectural designs and color schemes.

- Q: How do steel I-beams contribute to the overall safety of a structure?

- Steel I-beams contribute to the overall safety of a structure in several ways. Firstly, their design and construction make them incredibly strong and resistant to bending or twisting forces. This means that they can support heavy loads and distribute the weight evenly across the structure. By providing a strong and stable framework, steel I-beams minimize the risk of structural collapse, ensuring the safety of occupants. Additionally, steel I-beams have a high level of fire resistance. Steel has a high melting point, so it can withstand high temperatures for longer periods compared to other construction materials such as wood or concrete. This fire resistance reduces the risk of structural failure during a fire, giving occupants more time to evacuate the building safely. Moreover, steel I-beams are durable and long-lasting, with a high resistance to corrosion and degradation. This ensures that the structure remains intact and stable over time, reducing the risk of sudden failures or collapses. The strength and durability of steel I-beams also make them less susceptible to natural disasters such as earthquakes or strong winds, further enhancing the safety of the structure. In summary, steel I-beams contribute to the overall safety of a structure by providing a strong and stable framework, high fire resistance, and durability. Their ability to withstand heavy loads, distribute weight evenly, and resist bending or twisting forces ensures the structural integrity of the building, minimizing the risk of collapse. Combined with their fire resistance and durability, steel I-beams offer a reliable and secure foundation for a safe structure.

- Q: Can steel I-beams be used in architectural designs?

- Yes, steel I-beams can be used in architectural designs. Steel I-beams are commonly used in construction and are known for their strength and load-bearing capacity. They are often used in the construction of bridges, high-rise buildings, and other large structures. The use of steel I-beams allows architects and engineers to create designs with open and spacious floor plans, as they can support heavy loads and span long distances without the need for additional support columns or walls. Additionally, steel I-beams are durable and resistant to fire, making them suitable for various architectural applications.

- Q: Can steel I-beams be used for industrial platforms?

- Indeed, industrial platforms can utilize steel I-beams. The reason behind the popularity of steel I-beams for industrial platforms lies in their remarkable strength and durability. They possess the capability to bear substantial weights without succumbing to bending or warping, making them exceptionally suitable for industrial purposes. Moreover, steel I-beams can be effortlessly fabricated and tailored according to specific size and shape specifications, providing ample design flexibility. In conclusion, steel I-beams offer a dependable and economically efficient choice for the construction of industrial platforms.

- Q: How are steel I-beams transported and delivered to construction sites?

- Specialized equipment and vehicles are typically employed to transport and deliver steel I-beams to construction sites. To guarantee the secure and efficient delivery of these large and heavy structural components, the transportation process encompasses various steps. To begin with, steel I-beams are usually produced at steel mills or fabrication plants. Once manufacturing is complete, they are commonly loaded onto flatbed trucks or trailers. These trucks are equipped with cranes or other mechanisms for lifting, simplifying the loading and unloading of the I-beams. During transportation, the steel I-beams are firmly fastened onto the flatbed trucks using chains, straps, or other securing devices. This prevents any potential movement or damage while in transit. Special attention is given to maintaining balance and even distribution of the beams on the trailer to ensure stability and prevent accidents. In certain cases where the I-beams are excessively long or heavy to be transported as a single unit, they may be divided into smaller sections for easier handling and transportation. These sections are typically fused together at the construction site using welding or bolting techniques. Once the steel I-beams reach the construction site, they are cautiously unloaded using cranes or forklifts. The construction crew adheres to stringent safety protocols to guarantee the safe placement of the beams in the assigned area. The delivery process may involve coordination with the construction project manager or site supervisor to ensure timely and sequential delivery of the I-beams for the construction process. In conclusion, the transportation and delivery of steel I-beams to construction sites necessitate meticulous planning, coordination, and the utilization of specialized equipment. This guarantees the safe transportation and readiness for installation of these crucial structural components, thereby contributing to the progress of construction projects.

- Q: What does welded I-beam I400*1200*12*20 mean?

- The width of 400mm, height 1200mm, web thickness 12mm, the thickness of flange 20mm.Generally expressed as: height H * width B * web thickness t1 * wing plate thickness T2

- Q: Can steel I-beams be used for commercial office buildings?

- Yes, steel I-beams can indeed be used for commercial office buildings. Steel I-beams are commonly used in the construction of commercial buildings due to their high strength, durability, and ability to support heavy loads. They offer structural stability, allowing for larger open spaces and flexible floor layouts in office buildings. Additionally, steel I-beams are cost-effective, fire-resistant, and can be easily customized to meet specific design requirements, making them an ideal choice for commercial office construction.

Send your message to us

Steel Angle Bar Middle Size

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords