Steel I Beam Bar IPE for Structure Construction Normal Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel I Beam Bar IPE Description:

Steel I beam bar IPE is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel I beam IPE is usually made of structural steel and is used in construction and civil engineering. The web for Steel I beam IPE resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel I Beam IPE theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

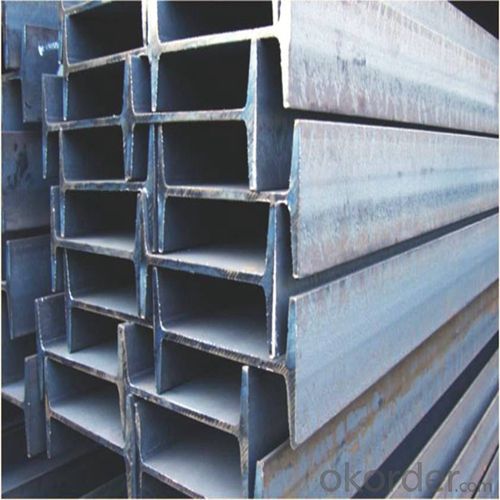

3. Steel I Beam Bar IPE Images:

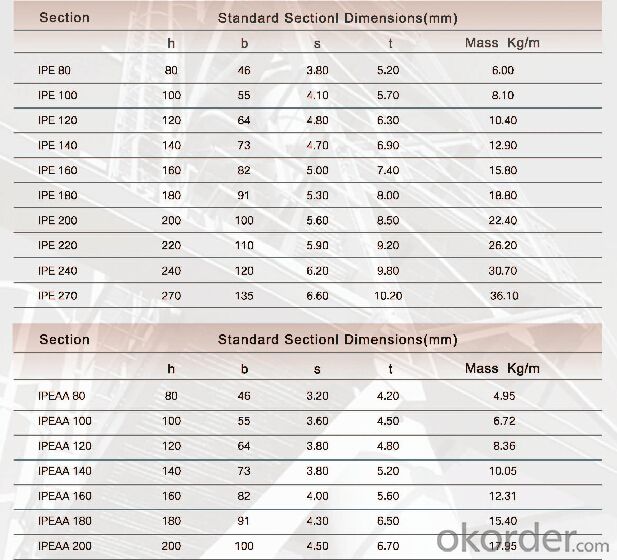

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can steel I-beams be used for schools and universities?

- Yes, steel I-beams can be used for schools and universities. They are commonly used in the construction of educational buildings due to their strength, durability, and ability to support heavy loads. Steel I-beams provide structural stability and can be designed to meet the specific needs of the building, making them a suitable choice for educational institutions.

- Q: How do steel I-beams perform in high wind conditions?

- Steel I-beams are known for their exceptional strength and durability, making them a popular choice for structural applications in high wind conditions. When subjected to strong winds, steel I-beams exhibit excellent resistance and performance due to their inherent stiffness and rigidity. The design of I-beams, with their flanges and web, allows them to efficiently distribute the wind load across their entire length. This characteristic helps to minimize deflection and prevent any potential structural failures. The compact shape of I-beams also reduces the occurrence of turbulence and wind vibrations, further enhancing their performance in high wind conditions. Furthermore, steel I-beams have a high strength-to-weight ratio, making them lightweight yet incredibly strong. This attribute allows them to withstand the dynamic forces generated by wind gusts and maintain their structural integrity. In addition to their material properties, steel I-beams can be further reinforced with additional elements such as lateral bracing or diagonal members to enhance their resistance against wind loads. These reinforcements help to minimize the likelihood of buckling or twisting under extreme wind conditions. Overall, steel I-beams are specifically designed and engineered to perform exceptionally well in high wind conditions. Their strength, rigidity, and ability to distribute loads effectively make them a reliable and robust choice for structures exposed to strong winds.

- Q: How do steel I-beams perform in terms of vibration control?

- Steel I-beams are widely recognized for their exceptional strength and load-bearing capabilities. However, when it comes to vibration control, their performance may vary depending on several factors. Firstly, steel I-beams have a natural frequency at which they tend to vibrate. This natural frequency is determined by their dimensions, material properties, and overall structural configuration. If the excitation frequency of the vibration matches the natural frequency of the beam, resonance can occur, leading to increased vibrations and potentially compromising the structural integrity. To mitigate vibrations in steel I-beams, several strategies can be employed. One common approach is to increase the stiffness of the beam by adding additional steel plates or braces. This increases the natural frequency of the beam, making it less susceptible to resonance with external vibrations. Additionally, damping systems can be incorporated into the design of steel I-beams to dissipate energy and reduce vibrations. These systems typically consist of damping materials, such as viscoelastic polymers or rubber pads, that absorb and dissipate vibrational energy. It is worth noting that the performance of steel I-beams in terms of vibration control can also be influenced by the surrounding structural elements and the overall design of the building or structure. For example, the presence of other damping elements, such as tuned mass dampers or base isolators, can further enhance the vibration control capabilities of steel I-beams. In summary, steel I-beams have inherent natural frequencies that can affect their performance in terms of vibration control. By increasing stiffness and incorporating damping systems, the vibrations can be mitigated and the overall structural integrity can be maintained. However, it is crucial to consider the specific design requirements and surrounding structural elements to optimize the vibration control performance of steel I-beams.

- Q: Can steel I-beams be used in energy-efficient building renovations?

- Yes, steel I-beams can be used in energy-efficient building renovations. Steel I-beams are known for their strength and durability, making them suitable for structural support in energy-efficient renovations. They can be used to reinforce the existing structure, support additional loads, or create open floor plans with larger spaces and better natural lighting. Additionally, steel is a recyclable material, aligning with the sustainability goals of energy-efficient building practices.

- Q: Can steel I-beams be used in residential deck construction?

- Steel I-beams, known for their strength and durability, are a viable option for residential deck construction. These beams can bear heavy loads and provide stability, ensuring the deck's longevity. While typically used in commercial and industrial projects, steel I-beams can also be employed in residential settings. This is particularly useful when a deck requires additional support due to its size or if it is being built on uneven ground. However, it is crucial to consult with a structural engineer or professional deck builder to ensure that the deck's specific design and construction requirements are met when utilizing steel I-beams. Moreover, adherence to local building codes and regulations is essential to guarantee compliance and safety standards.

- Q: What is the weight of a typical steel I-beam?

- The weight of a typical steel I-beam can vary depending on its size and dimensions. However, on average, a standard steel I-beam can weigh anywhere between 10 to 50 pounds per foot.

- Q: How are Steel I-Beams connected together?

- Steel I-beams are typically connected together using methods such as welding, bolting, or using specialized connectors like splice plates or shear connectors. These connections ensure structural integrity and stability in various construction applications.

- Q: How do engineers determine the appropriate size and type of steel I-beam for a project?

- Engineers determine the appropriate size and type of steel I-beam for a project by considering various factors such as the load requirements, span length, and structural design. They analyze the expected loads and forces that the beam will experience, including dead loads (weight of the structure itself), live loads (occupancy and usage), and environmental loads (wind, seismic activity). By performing calculations and simulations, engineers can determine the maximum bending moment, shear force, and deflection the beam will endure. They then refer to structural design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, to select a suitable size and type of steel I-beam that can safely support the anticipated loads while meeting the desired structural performance.

- Q: Are steel I-beams resistant to impact or shock loads?

- Generally, steel I-beams are resistant to impact or shock loads. Steel is a durable and strong material that can withstand significant forces, making it ideal for structural applications like I-beams. Steel I-beams can absorb and distribute energy throughout their structure when subjected to impact or shock loads, minimizing the potential for deformation or failure. However, it is important to consider that the resistance to impact or shock loads can vary depending on the dimensions, quality, and design of the steel I-beam. Furthermore, the overall structural integrity of the supporting components and connections must also be taken into account to ensure the I-beam effectively resists impact or shock loads.

- Q: Can steel I-beams be used in aviation or aerospace construction?

- Yes, steel I-beams can be used in aviation or aerospace construction, although they are not commonly used as the primary structural component. Steel I-beams are known for their strength and durability, making them suitable for various applications. In aviation and aerospace construction, however, weight is a critical factor, and steel is relatively heavy compared to other materials such as aluminum or composites. Therefore, while steel I-beams may be used in certain specialized areas or secondary structures where weight is less of a concern, the primary structural components in aviation and aerospace construction are typically made from lighter materials to optimize fuel efficiency and performance.

Send your message to us

Steel I Beam Bar IPE for Structure Construction Normal Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords