Hot Rolled Steel I-Beams with Highest Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

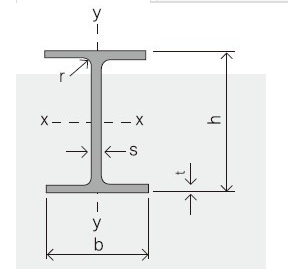

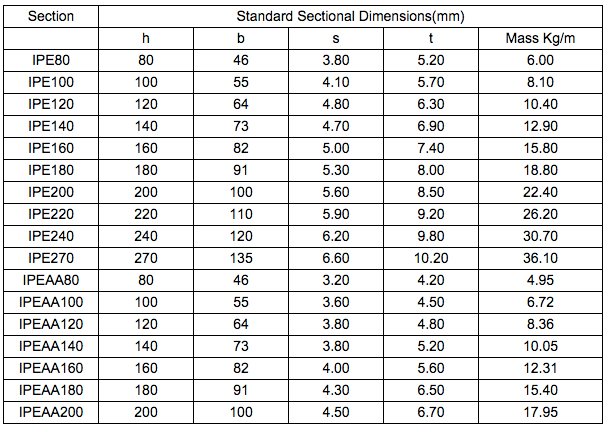

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

Q3:What's your payment terms ?

A3:Mostly,we collect the money by T/T and LC at sight . We also accept time LC at 90/120 days s

Q4: How do you guarantee the quality of products?

A4: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Images:

- Q: How do steel I-beams perform in terms of vibration insulation?

- Despite their excellent structural strength and load-bearing capacity, steel I-beams may not be the most effective choice when it comes to vibration insulation. Their rigid and inflexible nature tends to transmit vibrations rather than absorb or dampen them. Consequently, when exposed to vibrations caused by heavy machinery, earthquakes, or nearby traffic, steel I-beams can propagate these vibrations throughout the structure, potentially causing discomfort, noise, and even structural damage. To enhance the vibration insulation capabilities of steel I-beams, various measures can be taken. One commonly used approach is the incorporation of vibration isolation materials or techniques. These can involve the utilization of specialized rubber pads, foam inserts, or flexible connectors positioned between the steel beams and the surrounding structure. These materials and techniques are specifically designed to absorb and dampen vibrations, thereby reducing their transmission through the building. Another option involves implementing structural modifications that enhance the vibration insulation properties of steel I-beams. For instance, adding additional mass to the beams, such as by attaching concrete or other heavy materials, can help mitigate the transmission of vibrations. Additionally, introducing damping elements like tuned mass dampers or viscoelastic materials can effectively dissipate and attenuate vibrations, ultimately improving the overall vibration insulation performance. It is important to recognize that although steel I-beams may not possess inherent vibration insulation capabilities, they are often preferred for their strength, durability, and cost-effectiveness in structural applications. Therefore, a combination of appropriate design, engineering, and additional measures can be employed to minimize the adverse effects of vibrations and optimize the vibration insulation performance of steel I-beams.

- Q: How do steel I-beams contribute to the overall stability and strength of a structure?

- Steel I-beams contribute to the overall stability and strength of a structure by providing structural support and load-bearing capacity. The I-shaped design allows for efficient distribution of weight and forces, minimizing deflection and preventing structural failure. The beams' high strength-to-weight ratio allows for longer spans and taller structures, reducing the need for additional support columns. Additionally, their resistance to bending and torsion ensures the stability and rigidity of the entire structure, making steel I-beams an essential component for ensuring the overall integrity and safety of the building.

- Q: What are the cost considerations when using steel I-beams?

- When utilizing steel I-beams, there are various cost factors that need to be taken into account. Firstly, the cost of the steel itself plays a significant role. The price of steel can fluctuate depending on factors such as the steel grade, required quantity, and current market conditions. It is crucial to assess the cost of the steel beams in relation to the overall project budget. Aside from the steel cost, there are additional expenses to consider. The transportation and delivery costs of the steel beams should be included in the overall project budget. The size and weight of the beams can impact the shipping expenses, so it is important to plan for these costs accordingly. Moreover, the installation expenses of steel I-beams should be factored in. While steel beams are renowned for their strength and durability, skilled labor is required for their installation. This may involve hiring specialized contractors or construction teams, which can contribute to the overall project costs. It is vital to evaluate the expertise and experience necessary for the proper installation of steel I-beams and incorporate these costs into the project budget. Furthermore, the long-term costs associated with steel I-beams should be considered. Although steel is known for being durable and requiring low maintenance, it can still be susceptible to corrosion and wear over time. Implementing protective coatings or regular maintenance may be necessary to prolong the lifespan of the beams. These maintenance costs should be taken into account when assessing the overall cost-effectiveness of using steel I-beams. Lastly, it is crucial to evaluate the cost of alternative materials. While steel I-beams are frequently used in construction due to their strength and versatility, there may be alternative materials that offer similar attributes at a lower cost. It is essential to evaluate the specific project requirements and explore different material options to ensure the most cost-effective solution. In conclusion, the cost considerations when using steel I-beams encompass the price of the steel itself, transportation and delivery costs, installation expenses, long-term maintenance costs, and the evaluation of alternative materials. By carefully evaluating these factors, informed decisions can be made regarding the use of steel I-beams in construction projects.

- Q: How do steel I-beams perform in terms of fire protection?

- The fire protection performance of steel I-beams is commendable. The robust steel construction of I-beams grants them a formidable resistance to fire. When exposed to elevated temperatures, steel I-beams maintain their structural integrity without succumbing to collapse or deformation. This is due to the fact that steel possesses a high melting point and does not readily burn or ignite. Furthermore, steel I-beams exhibit a low thermal conductivity, resulting in a sluggish heat transfer. This characteristic effectively confines the spread of fire, preventing it from encroaching upon other sections of the edifice. To augment fire protection measures, steel I-beams can be coated with fire-resistant substances such as intumescent paints or sprayed-on fireproofing materials. These coatings form a barrier that impedes the rapid transmission of heat to the steel, thereby heightening its fire resistance. In general, steel I-beams are widely regarded as one of the most dependable and long-lasting materials for fire protection in structural applications. They find frequent utilization in tall buildings, industrial complexes, and other structures where fire safety is of utmost importance.

- Q: What are the independent foundations of the square column and the I-beam column?

- The steel column baseboard size is known, the independent foundation short column size request is bigger than the column baseboard, each side 100, and is bigger than the anchor bolt each side 5D and 150.

- Q: What are the potential hazards associated with steel I-beam installation?

- When installing steel I-beams, there are various hazards that must be considered. To begin with, mishandling the sheer weight of these beams can be extremely dangerous. They can weigh hundreds of pounds or more, and if they are not secured properly during installation, they can fall and cause severe injuries or even fatalities to workers or bystanders. Therefore, it is crucial to use appropriate lifting equipment and follow proper safety protocols to ensure that steel I-beams are handled and installed safely. Moreover, the installation process itself can be hazardous. Steel I-beams are often installed at elevated heights, increasing the risk of falls. To prevent this, workers must be equipped with fall protection gear, such as harnesses and safety nets, and proper scaffolding or platforms should be used to provide a stable work surface. Additionally, workers should receive training on proper lifting techniques and be mindful of potential pinch points or crush hazards during installation. Another hazard associated with steel I-beam installation is the potential for structural collapse. If the beams are not aligned, secured, or supported correctly, it can lead to catastrophic structural failure. Therefore, it is essential to have a qualified engineer or structural specialist oversee the installation process to ensure that all load-bearing requirements are met and that the beams are installed accurately. Lastly, there may be additional hazards specific to the installation environment. For instance, if the installation is being done in a confined space or an area with limited ventilation, there may be risks related to poor air quality or exposure to hazardous substances. Hence, it is important to evaluate and mitigate these potential hazards before commencing the installation process. In conclusion, the hazards associated with steel I-beam installation emphasize the importance of thorough planning, training, and adherence to safety protocols. By following best practices and ensuring that all necessary safety measures are in place, the risks can be minimized, and the installation process can be completed safely and efficiently.

- Q: What is the GB tolerance of I-beam?

- The allowable deviation of + 0.06t 1, the average thickness of steel legs.2. The bending deflection of I-beam should not exceed 0.15d.The outer edge of the slope 3, I-beam legs, one leg is not greater than 1.5%b, not more than 2.5% legs.4, steel legs, shoulder passivation shall not be equal to 0.18T diameter of the round bar through.

- Q: Can steel I-beams be used in bridges?

- Yes, steel I-beams can be used in bridges. In fact, they are commonly used in bridge construction due to their high strength-to-weight ratio, durability, and ability to withstand heavy loads.

- Q: Can steel I-beams be used for mezzanine storage systems?

- Yes, steel I-beams can be used for mezzanine storage systems. They are commonly used in constructing mezzanines due to their strength, durability, and load-bearing capacity. Steel I-beams provide the necessary support and stability required for safely storing heavy loads on mezzanine floors.

- Q: Can steel I-beams be used in historical building preservation projects?

- Yes, steel I-beams can be used in historical building preservation projects. Steel I-beams are often used as structural support elements in buildings due to their high strength and durability. When it comes to preserving historical buildings, it is important to balance the need for structural integrity with maintaining the original aesthetic and historical value. In many cases, using steel I-beams can help reinforce and stabilize the building, ensuring its longevity while still preserving its historical significance. Additionally, steel I-beams can be concealed within the structure or integrated into the design in a way that minimizes their visual impact on the building's historic features. Ultimately, the use of steel I-beams in historical building preservation projects should be carefully considered and evaluated on a case-by-case basis to ensure the best outcome for both structural stability and preservation of the building's architectural heritage.

Send your message to us

Hot Rolled Steel I-Beams with Highest Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords