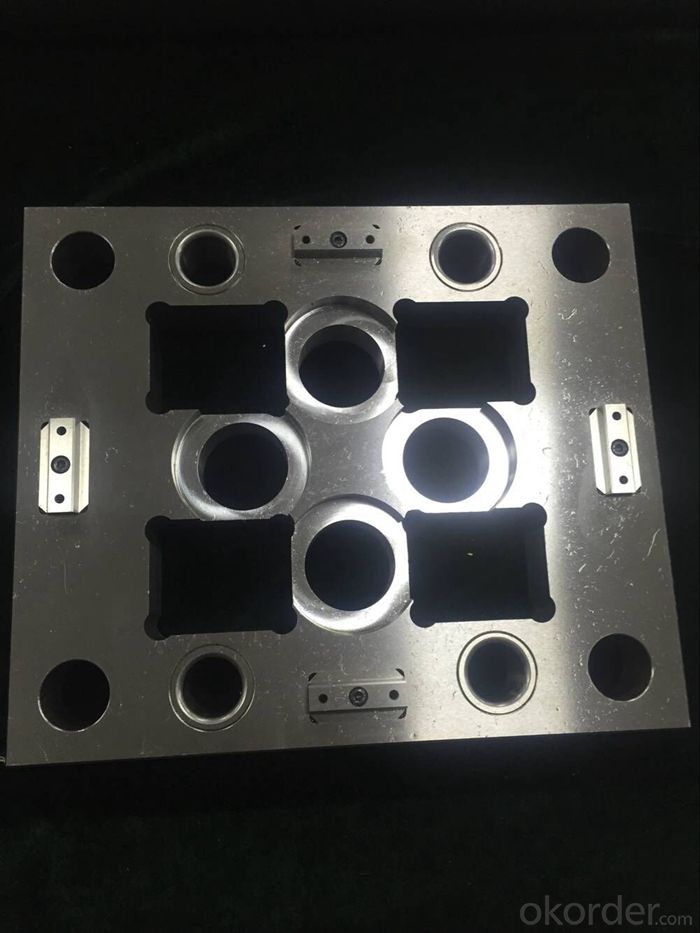

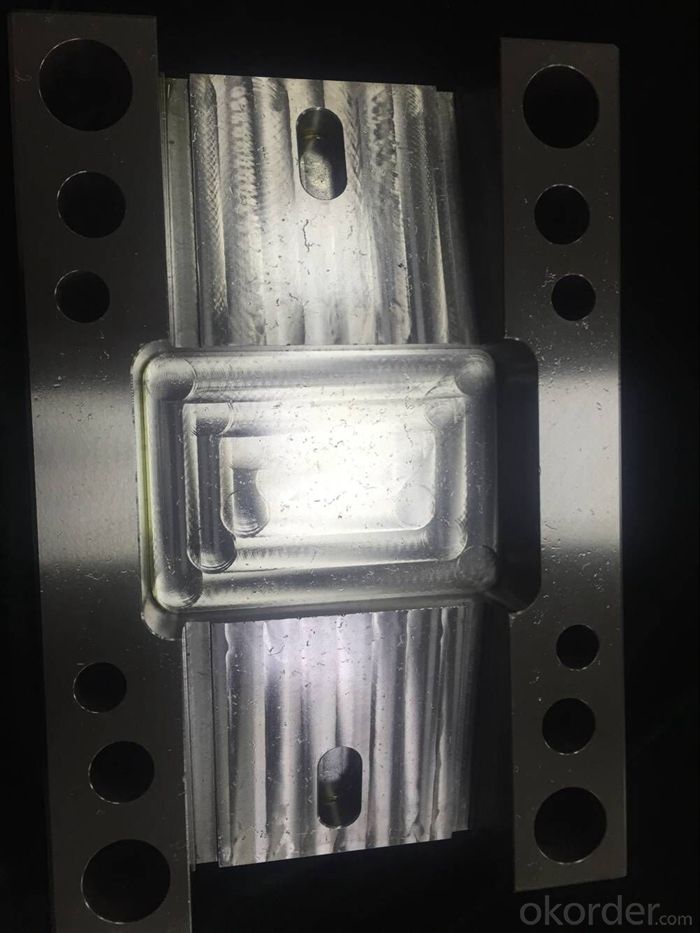

Standard Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: How many kinds of equipment can be used to open the mould?

- The molds have a lot of equipment Most basic: lathe, milling, grinding machine, line cutting, drilling machine These are the most basic. And, of course, you need to press the bed for the test

- Q: Is the slanting and shoveling chicken in the mold the same thing, shoveling the chicken? Where is it used?

- Oblique woven so rarely General said shovel chicken (tackle) you know oblique woven should know shovel base, its function is used to compress the slider, prevent when glue by shoot rubber pressure make the influence of the slider in the back.

- Q: What does the mold and the flying model mean

- B: it's the assembly mould. Where can't the qualified fitter fix it

- Q: What do you mean by plastic mold injection molding? What's the use?

- The assurance means a fixed pressure on the material in the mold. Because the plastic in the cooling process has the effect of heat bilges cold shrink, especially larger plastic shrinkage, heat bilges cold shrink is very obvious, so when we give the material after a fixed pressure, plastic shrinkage during the cooling process, the mold melt pressure began to decline, with the holding role, and the hydraulic system will automatically forward pressure, progress in the back of the material, added the contraction of the melt front, thus forming prevent products caused by shrinkage deformation. Adjust the pressure of pressure and the time of holding pressure, adjust the product defects such as the flying side, fuse connection and shrinkage mark.

- Q: The effect of mould preheating and several methods of preheating

- In order to protect the mould and improve the efficiency of the mould, it is necessary to keep the mould working in a certain temperature range as much as possible. If the mould no preheating, on the other hand, due to the mold temperature is low, it is easy to cause molding difficult, mucous membrane, the casting defects such as cracks, on the other hand, due to the mold temperature change is too big, hot and cold stress is very big, it is easy to mold damage, severe cases, may cause mould crack. Therefore, pre-heating is very important. According to the heating method, it can be divided into electric heating, natural (coal) gas heating and temperature heating. 1) electric heating: the heat tube is mainly heated by heat tube, which is clean and convenient to use. The drawback is that the thermal radiation is small. Die casting die is not adopted normally.

- Q: What is the design philosophy of the mould?

- The domestic development situation of facing the 21st century, the enterprise to adapt to the development of market economy, as the national support industry of the automobile industry will increase production of light, the micro, cars, thus puts forward higher requirements on the precision of the die forgings. In the process of production, improving die life is a complex and comprehensive problem. All forging technology, especially the net net shape and approximate shape processing technology, to a large extent depends on the precision and quality, mould depends on the skill level of the mould. Mould technology is reflected in die design and manufacturing, and die life is related to the use of the process. ? Is of great economic benefit to improve die life, generally in the trial production mold tooling costs accounted for about 25% of the cost of production, and finalize the design production is only 10%.

- Q: What is the main meaning of die mold?

- If you want to ask is flying (transliteration) mode, that is will be effected according to the intention of parting made of each piece of steel materials and replacement form closed (product cannot overflow burrs) the process of a block is said to fly.

- Q: The injection molding round box is not satisfied with the molds.

- Heat the mold with the temperature of the mould, then speed the injection a little faster, and then cool it when it is full.

- Q: Where is the mould industry in our country?

- Shanghai Shanghai has more than 1, 500 molds enterprises, with more than 70,000 employees and annual output of nearly 10 billion yuan, with an average annual growth rate of more than 20 percent. By 2010 the total output will be around 20 billion yuan. Imports from the current 290 million yuan based on compressed 30%, will increase 700 million yuan output value of industry, exports reached $130 million, and will increase 600 million yuan output value of industry. Shanghai mold industry will face six major industries and key industries, especially the information (IT) industry and automobile industry, vigorously develop the IT industry precision magnesium alloy die casting, precision injection mold; The auto industry covers molds, large parts die-casting molds and precision stamping parts. In 2010, 85 percent of the molds in the IT industry were manufactured and 90 percent of the auto molds were produced.

- Q: Why are the stamping molds wrinkling?

- The pressure side is small or the clearance is large, please check carefully.

Send your message to us

Standard Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords