Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

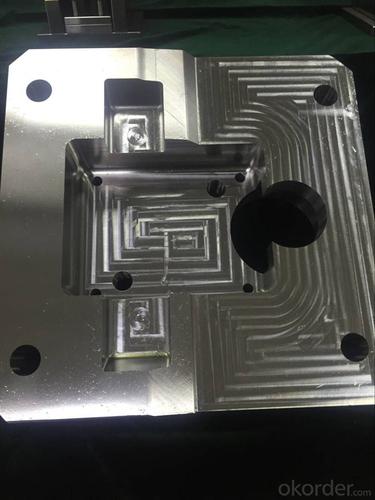

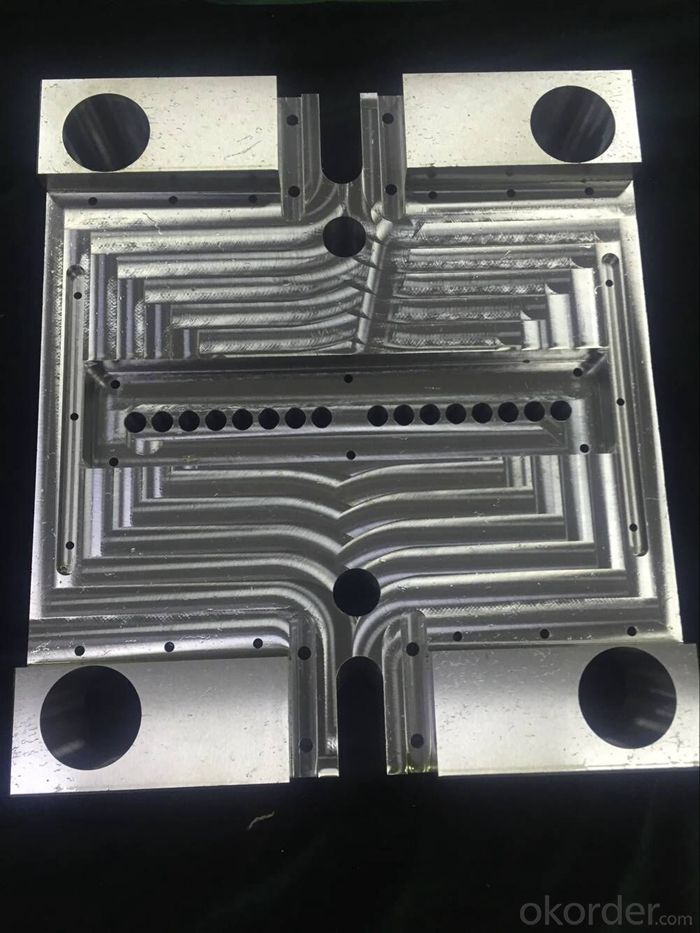

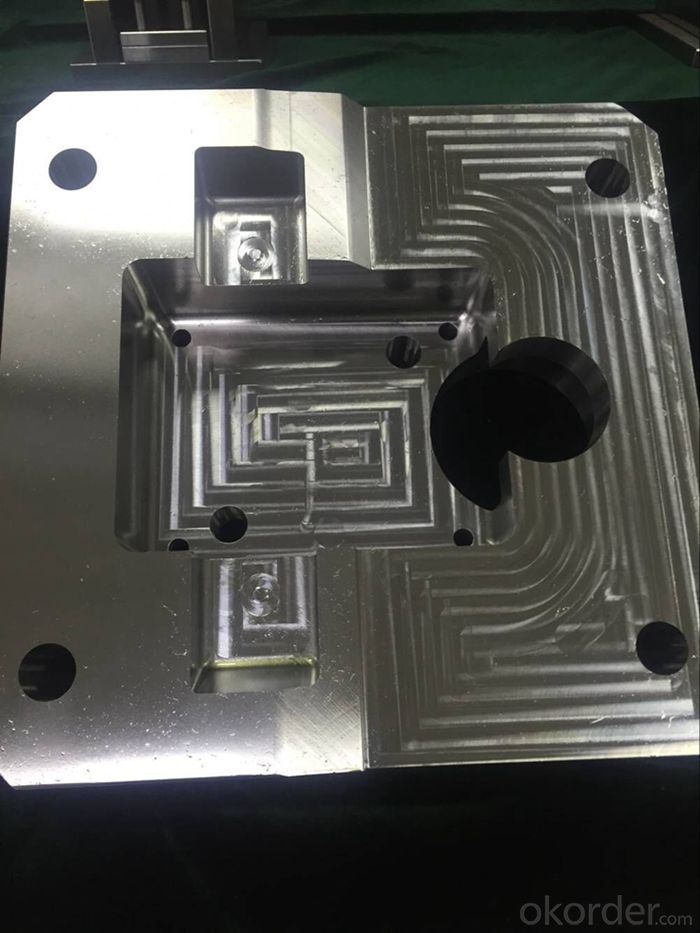

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: How to choose the injection molding machine when the mould design

- If you choose me as a manufacturer of injection molding machines, we will do our best to help you design the equipment you want

- Q: What does it mean to have a rough die

- The rougher is to cut off the material first. Some of the large excess is removed.

- Q: What is the mold for?

- As mentioned before, the plastic forming theory and mathematics modeling is not perfect, caused by stamping process analysis and formulation in the design phase is not perfect, need bench late a large number of debugging, this problem may be irremediable solution for, still can reason to evade a responsibility appropriately for designers, but the mechanical structure of the mould level is not good, for the kind of "line", as if we would be a little difficult to quit the effect, of course, I think it's also have many causes. First of all, the more high-end mold mechanical structure generally applied in complex parts and processes, such as car side plate, wing plates, engine hood pressing parts, such as domestic auto manufacturers due to many reasons such as sino-foreign joint venture, it is difficult to make the domestic mold enterprise manufacturing this kind of product of mold, new models of similar parts is often deprived, so we seldom opportunities for actual combat, some powerful manufacturers can be less in production tasks, practice habits conducted theoretical design, heaven knows earth knows the final effect is people do not know!

- Q: What is the difference between imported mold and domestic steel

- Comprehensive, mould life affected by various factors, imported steel in steelmaking technology, equipment, materials, smelting and forging technology, equipment, especially on the heat treatment process and equipment than domestic is has certain advantages, so the die life is higher and life is very stable. Currently used H13 die steel market is very chaotic, boasts, NAK80, 718 mostly imported materials, but according to my working experience for more than a decade, estimate of fraud in more than 50% (conservative estimate) Domestic at present commonly used die steel material, good is five, baosteel, fushun, zhongyuan special steel producers, such as smelting process in general vacuum arc furnace + + + electroslag refining heavy dissolved, the life of the small size mold and stability has been achieved and imported steel the same level. I personally feel that the big steel mills in China are not very serious at the moment, and they are too small in the promotion and development of the products.

- Q: What is the difference between a large water inlet and a thin nozzle?

- The difference between a large water inlet and a thin water nozzle: 1, from the entrance of the entrance to the glue mouth: one is the point gate (directly from the product to the glue) usually called the thin nozzle mold; One is from the side into the glue, gate is relatively big usually call gate mould (but sometimes think products turn into the glue need will do fine shuikou gate into the glue, structure and three board mould) Different from the structure of the mould: the two plates are usually called the large water port molds. There are two kinds of thin water mouth mould and thin water mouth mould.

- Q: What is the difference between a mold and a handboard?

- Hand refers to do manual model, general use plastic stick on machine tools or machining centers or in the form of a similar casting, made by hand, not mass production. And open mode is to point to the processing mould first, then use mould injection molding or blow moulding moulding to produce the product. In general, it is used to confirm the shape of the customer by hand plate mould.

- Q: What is the discharge in the die

- The principle of discharge machining is clear. I want to add: Electro discharge machining general use mould has more complex parts or features, other processing method will not be able to process the part, such as too small fillet and so on characteristics, due to other processing way knife can't reach, it is thought that if we do a bullnose matching, we put the bullnose electrode, electric spark processing parts of the corrosion products, finished products are formed a fillet in contrast to the electrode. This kind of processing is relatively slow, cost relatively high, commonly used for more precise die processing.

- Q: How do you handle the die holder

- Mould run burrs this directly associated with the precision of the mould processing 1: CNC processing aspect: parting surface machining with rubber products separately, do protect with mold clamp mouth out at the same time, avoid direct cause in the process of machining die round 2: split electrode aspects: faceted clear Angle of electrode to product rubber electrode, separately die fillet in the EDM process can be avoided

- Q: How do you play the continuous stretch mold

- It is almost impossible to form a single shape. The concrete steps are not clear, but the rough step is to pull the outside circle first, then take the small circle and take shape.

- Q: Is the stainless steel bowl replaceable in the oven?

- Normal stainless steel 4xx series chromium and 3xx chromium-nickel stainless steel in the oven temperature (250) the stability of materialization must be free of problem

Send your message to us

Mould Base for Plastic Injection Moulding Factory

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords