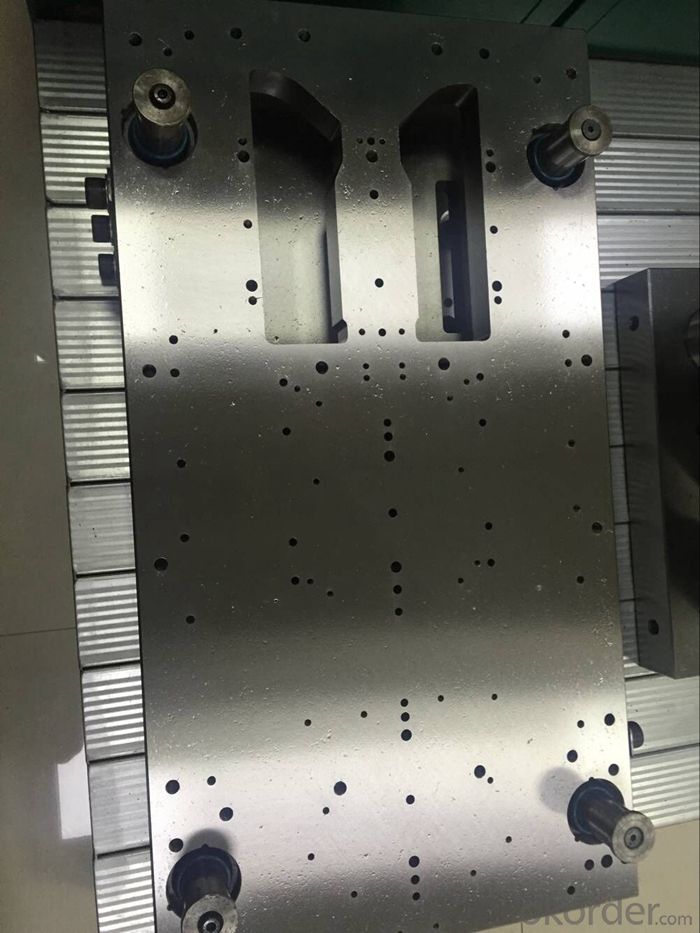

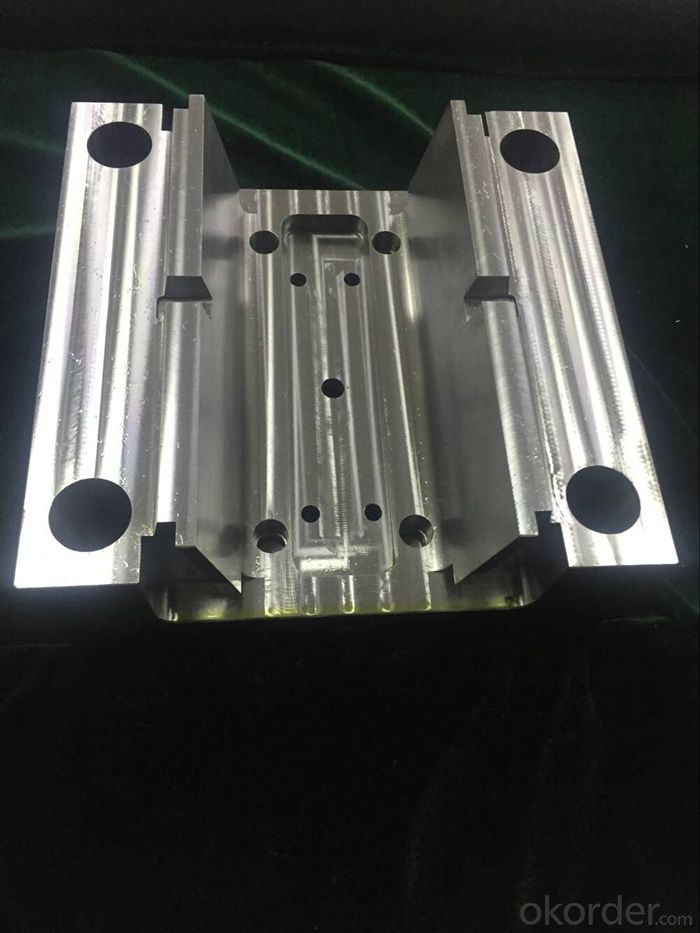

Euro HASCO Mould Frame Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: What is the material of hot pressing die?

- 5Cr4W5Mo2V (RM - 2) steel, more than 3Cr2W8V steel, has higher heat intensity, abrasion resistance and thermal stability. When the hardness of 40 HRC thermal stability of up to 700 ℃, suitable for the production of hot extrusion mould.

- Q: What kind of mold do you have?

- The mold is known as the mother of industry and the variety is very complex. The type of mould used is stamping die/injection mold/casting mould. Three types of molds are different.

- Q: The effect of mould preheating and several methods of preheating

- Mould temperature machine (oil) heating: the heating is even, the temperature adjustment adopts intelligent control, the temperature control accuracy is high, can meet the strict requirement of high craft standard. The operation control and safety monitoring device is fully complete, the heating process is fully automatic, the operation is simple, and the installation is convenient. Closed circuit heating, low heat loss, significant energy saving effect, no environmental pollution, wide range. The drawback is that heating is transmitted by heat, which is slower

- Q: What does the mold slow wire do

- Is walking wire edm wire cutting is a kind of English abbreviations (WEDM LS) is the use of continuous moving fine wire electrode (called wire electrode), pulsed spark discharge of artifact removal in metal, cutting shape. It is mainly used for processing of complex shape and small precision of workpiece, according to different wire electrode material (one is molybdenum wire, one is the copper wire), wire cutting machine tool is usually divided into two kinds: one kind is walking wire (wire electrode is copper wire), wire electrode for low-speed one-way movement, the general wire walking speed is lower than 0.2 m/s, the accuracy of 0.001 mm, and close to grinding surface quality level. The electrode filament is not used after discharge, the job is smooth, uniform, jitter and the quality of processing is better. Moreover, advanced power technology is adopted to achieve high speed processing, with maximum productivity of 350mm2 / min

- Q: What is a mold bite

- Make pattern, can make the surface of product surface and cavity surface can hold a small amount of air, do not form vacuum adsorption, make it easy to get out. Anti-skid, anti-roll, good handle. To make hemp or subsurface, prevent light reflection, eliminate eye strain and so on.

- Q: How to open the exhaust in the plastic mould exhaust, should notice what?

- Open vent, Injection mold opening the exhaust is used in order to avoid excessive due to the cavity pressure during injection and cause chat cannot fill mold cavity, makes the quality of the product is unqualified, general is in the parting surface out enough clearance, but the gap is smaller than the injection plastic material overflow value. It is the deep drawing depth that is to be opened in the stamping die, in order to make a piece from the convex model the need to make a hole in the deep direction of the convex mode, and then the hole is in. Insufficient filling is often found in injection molding production. Compressed air burns, high internal stresses, surface flow lines and fuse lines. In addition to adjusting the injection molding process first, it is also necessary to consider whether the mould gate is reasonable. When injection molding process and water sprue are excluded; The exhaust of the mold is the main problem, and the main method of solving the problem is to open the vent.

- Q: What is suitable for moulding steel

- Cold rolled molds include cold die, wire drawing die, drawing die, press die, thread rolling die, roller plate, cold press and cold extrusion die. Cold work die steel, according to the working conditions, and should have high hardness, strength, abrasion resistance and sufficient toughness, and high hardenability, hardenability and other process performance. Used for such purposes of alloy tool steel is generally belongs to the high carbon alloy steel, carbon mass fraction 0.80%, chromium is one of the important alloy elements such as steel, its mass fraction is usually not more than 5%. But for some high requirement of abrasion resistance, small deformation of mould steel after quenching, high chromium mass fraction is 13%, and in order to form a large number of carbide, carbon in steel quality score is high, up to 2.0% ~ 2.3%. The carbon content of the cold steel mold is high, and its organization is mostly in the form of a di-di-steel or lystenoid steel. Commonly used steel types have high carbon low alloy steel, high carbon high chromium steel, chrome molybdenum steel, medium carbon chromium tungsten steel, etc.

- Q: Is there any way to keep the ice from sticking to the mold and remove it from the mold

- In the hot water under the mould, soon the edge of the ice melts and buckles.After freezing, soak the die in the water and pull.

- Q: What is the pull mold

- The process of making sheet metal material into a bowl or can is called a drawing die. For example, the process equipment that makes the aluminum plate into a can is a kind of pull mold.

- Q: What is the difference between the mold and the numerical control? The difference is?

- The design process of the tool and the performance of the materials needed are designed CNC is mainly for nc machine tools, need programming digital controlled drawing mould, in short, the mould is used for molding tool, this tool has all parts, different mould made up of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance. The mold can be divided into metal mould and non-metallic mould according to the material that is formed. The metal mould is divided into: casting mould (non-ferrous metal casting, steel casting) and forging die etc. Non-metallic mold is also divided into: plastic mould and inorganic non-metallic mould. And according to the material of the mould itself, the mold can be divided into: sand mold, metal mould, vacuum mold, paraffin mold and so on. With the rapid development of polymer plastics, plastic mould is closely related to people's life. Plastic mould can be divided into: injection molding mold, extrusion molding mold, gas auxiliary molding mould and so on.

Send your message to us

Euro HASCO Mould Frame Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords