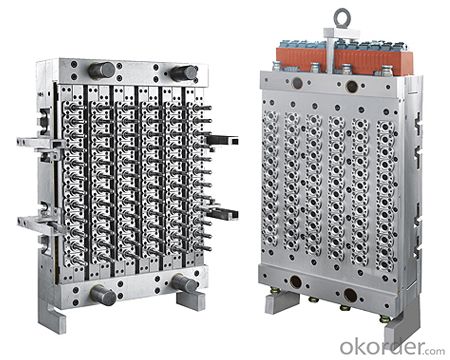

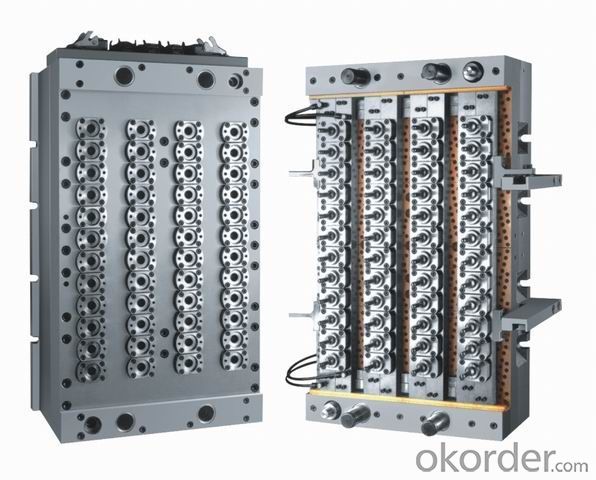

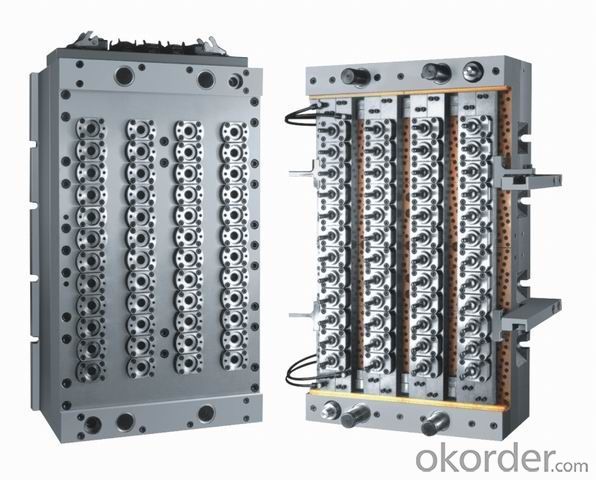

Multi-Cavities PP Preform Mould with Hot Runner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Multi-Cavities PP Preform Mould

The mould is made of high quality steel; the hot runner adopts needle valve balance type plastic feeding; the temperature control system adopts PID single-cavity independent control, so it has very little temperature error and has short molding period; the product has beautiful appearance and very small size error and very high qualification ratio.

2. Main Features of Multi-Cavities PP Preform Mould

| mould specs | Mould Dimension (L * W * H) |

32-cavity (PET) valve gate preform | 815*610*500550 |

48-cavity (PET) valve gate preform | 1100*610*500550 |

72-cavity (PET) valve gate preform | 1100*850*550650 |

96-cavity (PET) valve gate preform | |

| 128- cavity (PET) valve gate preform |

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

The company can provide full no-man bottle preform product line, which includes injection machine, mould robotic arm and moulds.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: What does the mold change mean

- The change is said to be: because the product is not mature, need to change, cause the need to make change on the mould, or reprocessing!

- Q: Is there a difference between die and CNC

- Mold and nc are two different directions, a partial design, a partial manufacturing, also have a call mould in nc programming, but still belongs to the CNC mould design class, salary difference is very big, generally what percentage according to the design of the mould, so great, but demand is high, the so-called old to incense, so have millions of annual salary. Such people are experienced. It takes a certain amount of time to go this route, and it's not a college, but an undergraduate. The real mold, there are a couple of possible ways to get started, 1, this is a graduate, and it's a couple of years, you know, you know, you know, you know, you know, you know, you know, you know, you know, you know,

- Q: The effect of mould preheating and several methods of preheating

- In order to protect the mould and improve the efficiency of the mould, it is necessary to keep the mould working in a certain temperature range as much as possible. If the mould no preheating, on the other hand, due to the mold temperature is low, it is easy to cause molding difficult, mucous membrane, the casting defects such as cracks, on the other hand, due to the mold temperature change is too big, hot and cold stress is very big, it is easy to mold damage, severe cases, may cause mould crack. Therefore, pre-heating is very important. According to the heating method, it can be divided into electric heating, natural (coal) gas heating and temperature heating. 1) electric heating: the heat tube is mainly heated by heat tube, which is clean and convenient to use. The drawback is that the thermal radiation is small. Die casting die is not adopted normally.

- Q: The difference between wire cutting and mold making

- How much do you need for the number of samples? If the number is small, the line cut is cost-effective (low cost). We will not open the mould until the customer has decided to make the batch. The cost of the die will be spread to each product, so the cost of the die will be reduced. If the mould comes up, the mold will be open if the customer is not satisfied. Money spent. I don't know. Do you understand?

- Q: What are the advantages of using a hot runner?

- Save plastics raw materials There is no production charge in the pure heat flow mold because there is no cold water. This is especially important for the expensive application of plastic. In fact, the world's leading manufacturers of hot water production have been developing rapidly in the world's expensive years of oil and plastics. Because the hot runner technology is an effective way to reduce the cost of materials. Reduce waste and improve product quality The plastic melt temperature is controlled accurately in the flow system during the process of hot runner mould forming. The plastic can flow in more uniform and uniform state, and the result is a uniform component. The parts of hot runner forming are good quality, the residual stress is low and the parts are small. So many of the high quality products in the market are made by hot runner mold. Many of the plastic parts in the DELL laptop, such as the familiar MOTOROLA phone and the HP printer, are made using hot stream molds.

- Q: The stamping dies at the Angle of 90 degrees, the Angle is big or small how to repair.

- The Angle size can be changed by adjusting the stroke, increasing the pressure and reducing the stroke. Small to reduce the pressure, the trip increases. There's always going to be an R Angle at 90 degrees, and it's going to get bigger and bigger.

- Q: What do you do with the exhaust? How are we going to

- There are many ways to exhaust the cavity, but every method must be guaranteed: the exhaust groove should be designed to prevent the material from spilling into the slot. The second is to prevent blockage. Therefore, from the surface of the cavity of the cavity to the cavity of the cavity in the cavity of the cavity, the exhaust tank of 6 to 12mm long, the slot height should be about 0.25 to 0.4 mm. In addition, the number of exhaust slots is harmful. It is dangerous to cause cold flow or fissure in the cavity material if the mode of the lock mode is very high in the part of the cavity that is not open. In addition to outside the parting surface of cavity exhaust, also can be in the end of the pouring system of material flow set exhaust slot location, and leave gaps around the ejector rod achieve the goal of exhaust. Because of the depth, width, and location of the exhaust groove; If not properly, the resulting spines will affect the aesthetics and accuracy of the products. Therefore, the size of the above clearance is to prevent the appearance of the flying side near the top of the rod. It should be noted that in the exhaust of the gear such as gears, it may not be possible to have even the smallest edge. This type of assembly is best to exhaust the air in the following way. The size of 200 # carbide abrasive is applied to the surface of the parting surface. In addition, in the end of the pouring system of material flow to open exhaust slot is mainly refers to the position at the end of the shunt way exhaust slot, its width should be equal to the width of the distributary channel, height varies depending on the material.

- Q: How do you play the continuous stretch mold

- Don't listen to that one, he only understands the words in the paper, he can't use it! First, the outside big circle is in pull small circle perhaps dead fixed! How high is the large circle? How much is the smaller circle? Tell me the data and contact me again!

- Q: What are the career prospects of the mould profession

- According to the relevant responsible person, the mould student has not finished the business, there is a lot of the enterprise to make the booking, in advance to negotiate with the student. So far, the company opened a minimum monthly salary of 3000 yuan, in the past to students have work experience in mold industry, many enterprises with annual salary of $100000 to hire go dongguan yearly salary 100000 senior mould talents. From dongguan talent market, according to the latest news from the shortage of at least 3000 senior mold talent, dongguan city, with a professionally trained in PRO/E, UG, etc, have working experience in mold design, mold manufacturing and technical personnel, salary is often more than 100000 yuan.

- Q: What is the use of the mold collecting water

- How do you understand that a thick pipe is divided into a few or dozens of thin pipes? A water block switch is required in the middle.

Send your message to us

Multi-Cavities PP Preform Mould with Hot Runner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches