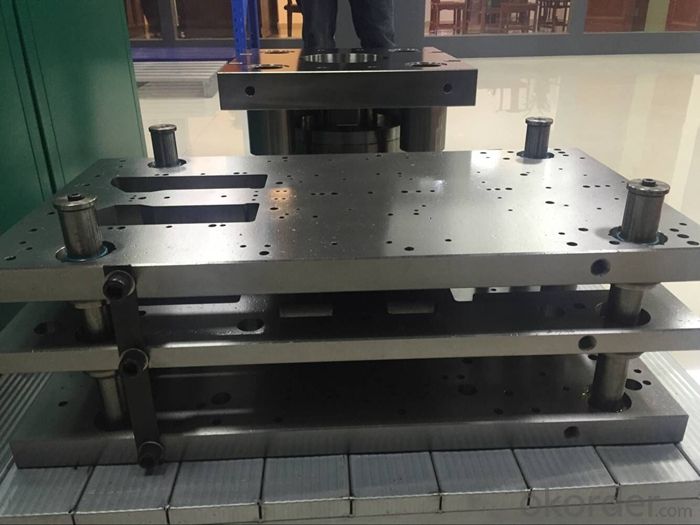

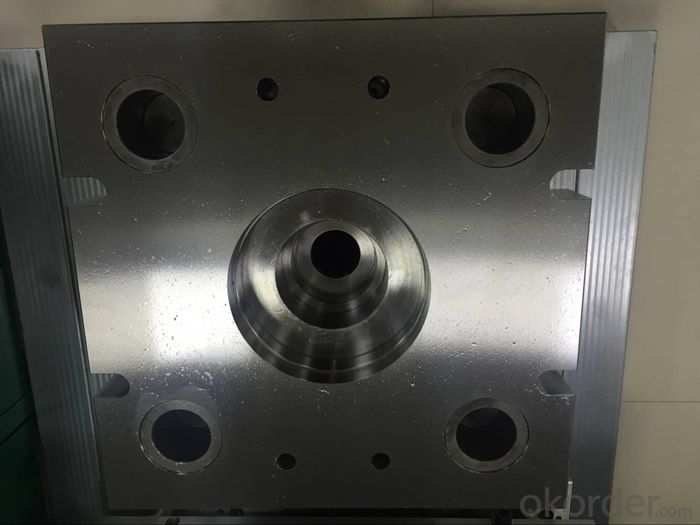

Die-casting Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: What effect is the flange of the die

- Flanges are concentric with the jw, flanged, and the nozzle of the injection-molding machine, the flanged design corresponds to the size of the machine. 1, flanges, or flanged flanges or flanges. The flange is the part of the pipe that is connected to the pipe and is used for the connection between the end of the pipe. Also useful for the flange of the equipment import and export, for the connection between two devices, such as reducer flanges. Flange connection or flanged joint, which refers to the disconnection of a combination of flange, gasket and bolt. The pipe flanged flanged is a fitting flange for the piping device, which is used to refer to the equipment's import and export flanges. There are holes in the flanges, and bolts make two flanges. The flange is sealed with gasket.

- Q: The role of cryogenic processing of die material

- Deep cold will change some mechanical properties, and the main effect will be as follows: Enhance the hardness and strength of the workpiece Ensure the precision of the workpiece Improve the wear resistance of the workpiece Improve the impact toughness of the workpiece Improve the internal stress distribution of the workpiece and increase the fatigue strength Improve the corrosion resistance of the workpiece.

- Q: How do H13 mould steel heat treatment

- 2. The quenching and tempering toughness good die quenching process specification: heating temperature of 1020 ~ 1050 ℃, oil cooling or air cooling, 54 ~ 58 HRC hardness; For hot hard mould quenching technology, heating temperature of 1050 ~ 1080 ℃, oil cooling, 56 ~ 58 HRC hardness. Recommend a tempering temperature: 530 ~ 560 ℃, 48 ~ 52 HRC hardness; Tempering temperature 560 ~ 580 ℃; 47 ~ 49 HRC hardness. Tempering should be twice. At 500 ℃ tempering, tempering the secondary hardening peak, tempering hardness, the highest peak at about 55 HRC, but toughness is the worst. Therefore, tempering process to avoid around 500 ℃ advisable. According to the use of mould need, within the range of 540 ~ 620 ℃ tempering. Quenching heating should be two preheating (600 ~ 650 ℃, 600 ~ 850 ℃), in order to reduce heating process to produce thermal stress.

- Q: What is the difference between the p20 mould steel and the nak80-b mould steel

- P20 mould steel is American, its main application range is: the requirement of high hardness, high quality, good wear-resistant plastic mold, Nak80-b mould steel is a Japanese cargo, and its main application is: require hardness, erosion, and polishing. Also: nak80-b is harder than P20; Of course the price is more than the P20.

- Q: What does the mold and the flying model mean

- That's the model, Hong Kong. The British side to FIT.I hope my answer will help you

- Q: What do you mean by plastic mold injection molding? What's the use?

- Bao subsection to the holding pressure and holding time, at the time of injection molding, about 1-2 seconds can not the mould cavity while curing fill, and then the molten plastic cooling in the mold, the volume will narrow. So after injection molding for 1 to 2 seconds, you set the pressure time and pressure pressure to continue to press the plastic into the mold, and time is the time

- Q: Is there a difference between die and CNC

- In this industry for a long time, such as the above mentioned anything very tired what some content (which is fitter), such as after contact with these can promote the theory knowledge, can such as the door. Has a common characteristic is one of the two mold design knowledge, the knowledge of the actual mold edge or the manufacture of understand relevant knowledge, above all, the mould design of the road is long, don't be afraid of bitter, in front of the stick behind natural results. The numerical control is relatively less long-term, learn to do, the big deal starts from the foundation. Relatively simple. If you haven't learned it, you can do it, you can do the operator, it's the machine, you move the parts. The treatment is basically between 1,500 and 3,500, and of course there are over 4,000, very few, after all, it's manual labor, it's a piece of work, it shouldn't be done in a few months. The real technology is to learn. The first is programming.

- Q: What are the molding methods of plastic molding mould?

- Plastic blow molding mold: is used for molding plastic hollow container class products (such as beverage bottle, cosmetic products all kinds of packaging containers) of a mold, blow moulding main form according to the process principle of extrusion blow molding hollow molding, injection molding, main form according to the process principle of extrusion blow molding hollow molding, injection blow molding hollow molding, injection stretch blow molding hollow molding (commonly known as "note" blowing), multi-story hollow blow molding, sheet molding hollow molding, etc. The equipment of hollow product blowing and molding is usually called plastic blow molding machine, and blow molding is applied only to the production of hot plastic variety products. The structure of blowing mold is relatively simple, and the materials used are made of more carbon.

- Q: What is the difference between imported mold and domestic steel

- One, the biggest difference is the price of imported materials is high, commonly in domestic material more than double. Second, steelmaking technology perspective, foreign well-known steel material generally purity of molten steel is higher, P, S, and five element content is low, low gas content, is simply less impurity. From the forging point of view, the imported mould steel is generally good, the forging pressure is bigger than the big, simply it is the uniform and transparent of forging. Four terms, heat treatment, the overseas research and development efforts, compare the commonly used die steel are basically developed abroad, so the heat treatment craft is advanced, and the equipment is advanced.

- Q: What mould steel can make injection mold?

- Plastic mold with steel characteristics and USES The steel P20 belongs to low carbon steel, low strength, toughness, plasticity and weldability are good, it is mainly used for cavity is simple, small batch production of plastic mold, anti-indian method is used to manufacture the mold, then the carburizing and quenching and tempering treatment, can obtain high hardness and wear resistance, appearance of heart toughness good mould. 20 cr is one of the largest of several alloy structural steel production in our country, the application is very extensive, more than 20 steel has good hardenability, moderate strength and toughness, after carburizing treatment, has the very high hardness, wear resistance and corrosion resistance of the appropriate, as the usage of the plastic die steel with 20 steel 45 steel is China's current higher strength and better cutting workability, after proper heat treatment, can obtain a certain toughness, plastic, and wear resistance, convenient material source, generally after the conditioning, manufacturing plastic mold, is our country at present plastic mold used steel is one of the most widely steel grade 40 cr tensile strength and yield strength of the steel is higher than the corresponding carbon steel by 20%, and has good hardenability, good machinability, the steel manufacturing plastic mold and after carburizing and carbonitriding treatment, can improve the wear resistance and corrosion resistance

Send your message to us

Die-casting Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords