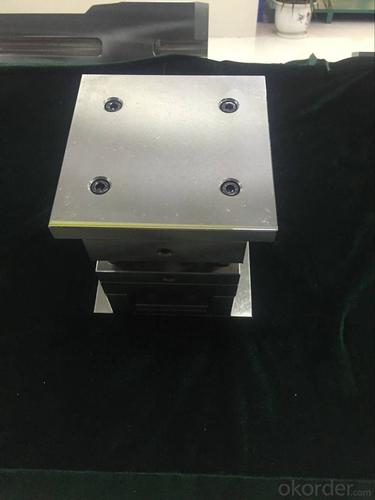

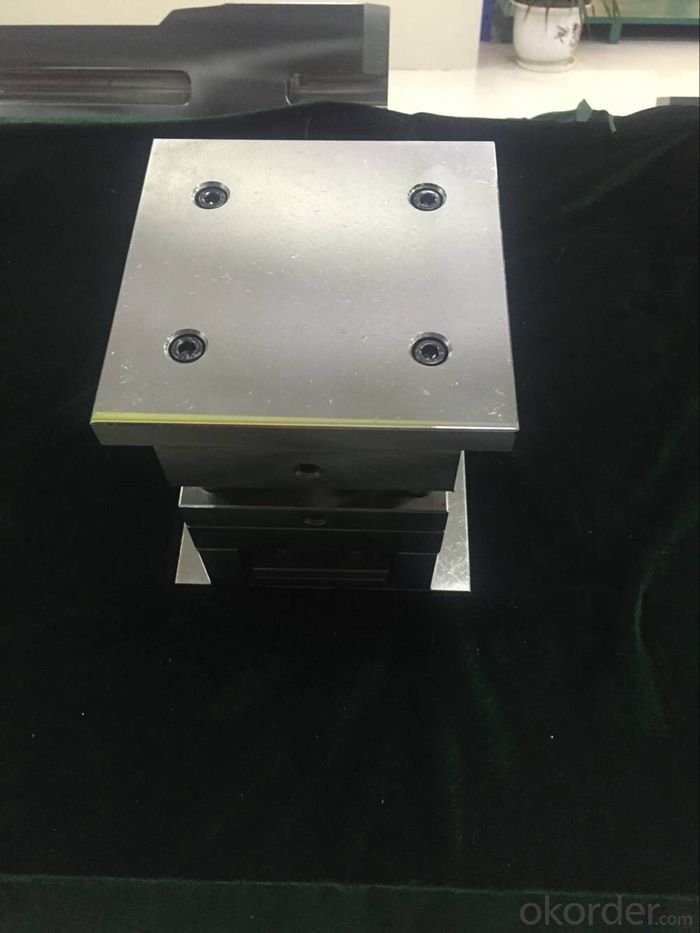

Stamping Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

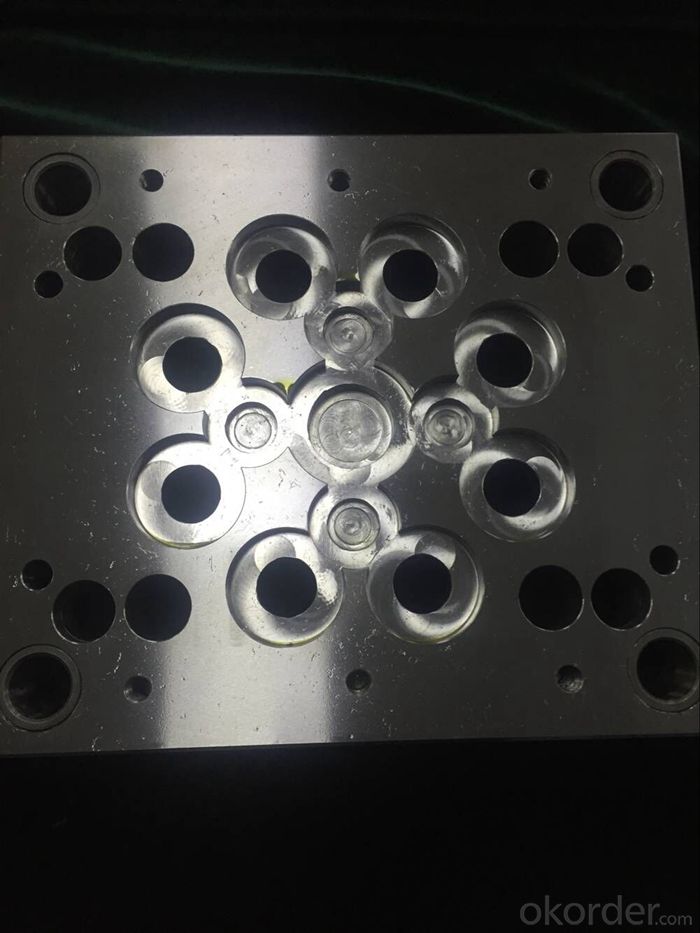

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q: The role of cryogenic processing of die material

- Cryogenic processing can improve the performance of various materials. In the mould materials, it is mainly possible to improve the wearability, the prolonged impact fatigue strength, the ductility of the material and the internal deformation.

- Q: Is the digital control the same as the mold? If not, what's the difference?

- There is a difference, the numerical control is a kind of lathe! The mold is a large scale model! They're very different

- Q: Is there a difference between die and CNC

- Need to master the tools design process of the tools and materials required for the performance of the design of CNC is mainly for nc machine tool operation, need a digital programming reference drawings

- Q: How to calculate the weight of die steel?

- The proportion of some steel is: industrial pure iron 7.87; Cast steel is 7.8; Steel 7.85; Cast steel is 7.8; Low carbon steel (carbon 0.1) 7.85; Medium carbon steel (containing 0.4%) 7.82; High carbon steel (1 percent carbon) 7.81 is: gram/square centimeter assumes you are the average steel that is "7.85 gram/square centimeter".

- Q: Make the mold with the dough

- Theoretically possible, but be aware of the following points: When taking the true model out, try to avoid the distortion of the internal cavity of the dough. The deformation of the cavity directly affects the later production accuracy.

- Q: Is there any way to keep the ice from sticking to the mold and remove it from the mold

- The best way is normal with mold, ice, frozen after good, put the mold in bowl with cold water for a while is ok, it is not necessary to use warm water, don't have to put the water into ice. And then you take it, and then you have a twist on both ends of the mold.

- Q: Because many of the molds in our factory have batch sewing, who can tell me how to fix the batch seam. Because I don't understand, but I'm going to learn, so I want to know in advance, thank you very much!

- If solve the above problem is mould itself reason, please use red lead to mold fitting well, the original poster check mold in touch wear, wear a location, see if cooperate in place.

- Q: How do you play the continuous stretch mold

- More than 3 Zhang Chengpin photos Now want to know how he made, and calculate methods and specific steps, he is the one step forming or stretch forming step by step.

- Q: Why are the stamping molds wrinkling?

- The pressure side is small or the clearance is large, please check carefully.

- Q: Introduction to mould design and manufacturing

- Develop mold design and manufacturing of advanced applied technology talents, graduates can be engaged in the enterprise production fixtures and tools needed for the design and manufacturing, mold assembly and debugging, mold enterprise operation and management. Main course: mechanical drawing, mechanical design and foundation, cold stamping die design and manufacture, design and manufacture of injection moulds, and the programming of numerical control technology, mould processing machinery, electrician and electronic technology, hydraulic and pneumatic transmission, metal cutting principle, mechanical CAD/CAM, etc. One, cultivate goals This professional training support the party's basic line, to adapt to the production, construction, management and service first line need, moral, intellectual, physical, beauty and other aspects of comprehensive development, mold design and manufacturing of the basic theory and knowledge, engaged in mold design and processing, manufacturing, and maintenance of advanced technology applied talents.

Send your message to us

Stamping Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords