Injection Hot Runner PET Preform Mold for Mineral Water Bottle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

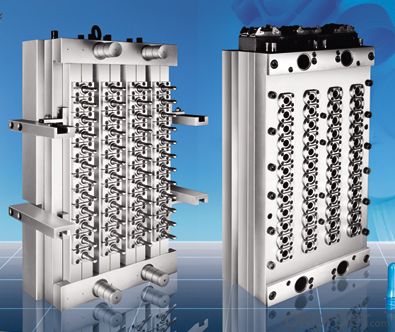

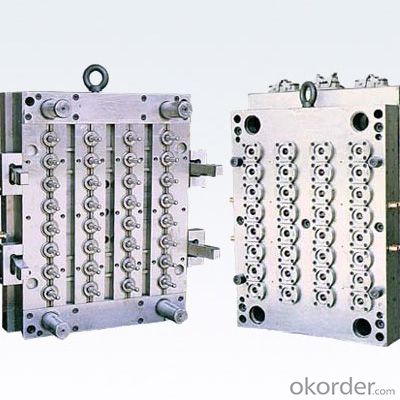

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

. Features of the perform mold. No cutting of valve gate is employed to reduce the labor cost.

. Advanced hot runner system assures lower level of AA value.

. Reasonable- designed cold water channels increase cooling effect and shorten the cycle time.

. The main components of perform molds are made of 2316 material (Sweden ASSAB).

. The mold base is made of imported P20. plate method avoids corrosion efficaciously and assures long life service of the perform molds.

. German Vacuum stove is imported for heat treatment of the components, which assures the hardness of components HRC45-HRC48.

. Many machine tools are imported from America and Japan, such as Machine center, CNC lathers, EDM and so on. All of these increases processing precision, good interchangeability and low eccentricity ≤0.10mm (perform length≤100).

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: The application of hydraulic cylinder in mould

- Hydraulic cylinder: hydraulic cylinder is a hydraulic actuator that transforms hydraulic energy into mechanical energy, and is a linear reciprocating movement (or movement). It is simple and reliable. Use it to realize reciprocating motion, the speed reducer can be avoided, and there is no transmission clearance, the smooth movement, thus is widely used in all kinds of mechanical hydraulic system. The output force of the hydraulic cylinder is proportional to the effective area of the piston and the pressure difference between the two sides; The hydraulic cylinder is composed of cylinder and cylinder, piston and piston rod, sealing device, buffer and exhaust device. The buffer device and the exhaust device depend on the specific application, and other devices are necessary

- Q: What is the difference between the p20 mould steel and the nak80-b mould steel

- It's completely different, the composition is different, P20 is 3Cr2Mo, and NAK80 is 10Ni3MnCuAl

- Q: Why does the mold exhaust, so where does the gas come from

- Just add a little bit of the purpose of the exhaust: burn. The other ten is perfect.Plastic mold venting is not good, the gases in the cavity is compressed, produce a lot of pressure, this is the back pressure to prevent the molten plastic for normal rapid molding, make it difficult to injection molding. Once injection molding difficulty in this case, the researchers often adopt the method of improve the injection pressure of injection, this led to the pressure maintaining prolonged, molding cycle delay, the production efficiency is lower, injection molding machine energy consumption increases and so on. Even corrosive gases are sometimes fouled in the cavity, contaminating plastic molds, reducing the life of the molds and increasing the cost of plastic moulds.

- Q: What is the number of holes in the mold?

- The number of cavity is the number of cavity, the number of parts that can be formed.

- Q: Injection mold. What does the soft mold mean? What's the difference between a quick one?

- A soft die is a concept that is relative to a hard mold. In the process of component design generally need to verify the design of plastic parts is reasonable, can meet the requirements of the assembly and product design changes may need to be kept. This way, we need to open a sample molds before mass production. Until the design is no longer changed, the initial mass production is limited to a single hole of capacity, which requires a large cavity. In the comparison between soft and hard models, the soft mold is not as good as the hard mold (which is the die life), except for the steel choice. What do you mean by a quick form that you don't understand? Is it a plastic block? If this is the case, then a quick form is not needed, but only a few or dozens of samples can be done, and the cost is high. The average life span of a soft mold is no less than 50,000 modules, even higher. If batch not small plastic parts, often one a hole to use soft model completely can satisfy capacity.

- Q: What is the difference between imported mold and domestic steel

- Look not to come out from the appearance, warranty can be divided, but did not rule out the JS, use should be able to separate, but does not rule out the use of high quality domestic steel service life is better than imported steel and when selling imported steel.

- Q: How is the die in the manufacturing industry

- If you are a production company, you can buy it as a tool and sell it as a material sale. Purchase: low value consumables - molds Taxes should be paid in the form of VAT Bank deposits (or accounts payable) Sales: bank deposits (or accounts receivable) Other business income - material sales Tax payable - value-added tax Cost of transfer: other business costs Low value of the loan - molds Welcome to use the "fiscal and tax question-and-answer community" for financial advice

- Q: What are the advantages of using a hot runner?

- Choose the right heat flow. The easiest thing to do is save money and save a minimum of labor.

- Q: How do you play the continuous stretch mold

- It is almost impossible to form a single shape. The concrete steps are not clear, but the rough step is to pull the outside circle first, then take the small circle and take shape.

- Q: What is the "KO hole" on the injection mold?

- KO hole, also called the top roller, is to do in the mold after the mold on the front panel, in order to make injection molding machine ejection, top stick can directly to the plunger on a board, and dig holes on the panel to avoid empty. The location of the KO hole is on the same axis as the spout. Sometimes according to the actual situation of the mold to open several KO hole, then according to the dynamic injection molding machine template parameters to determine the location of the KO hole, other is already open on because of the injection molding machine template for porous as caving sticks.

Send your message to us

Injection Hot Runner PET Preform Mold for Mineral Water Bottle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords