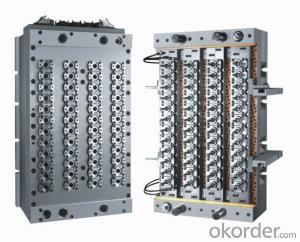

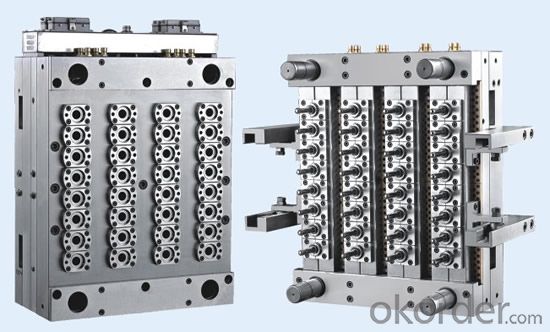

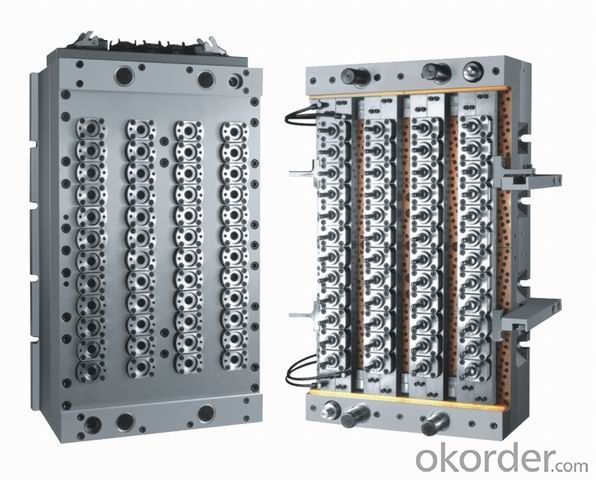

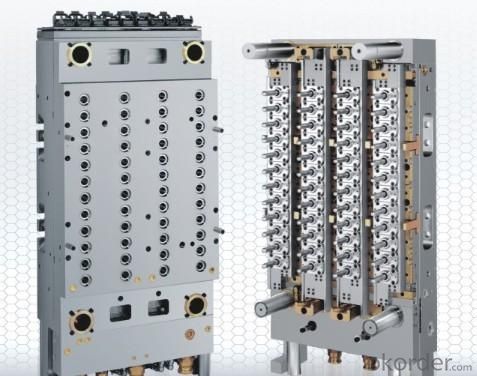

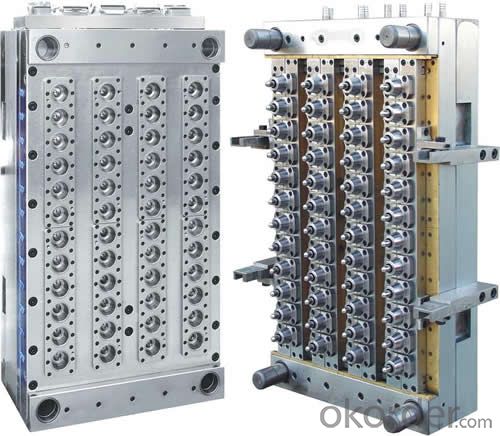

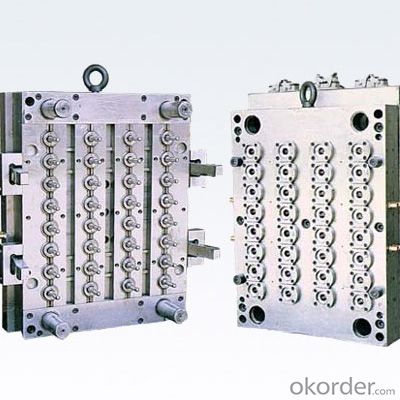

Plastic Injection Mould Multi-cavities Hot Runner Plastic PET Perform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

.Off-center Adjustment System

Off-center adjustment system can make the error of preform’s wall thickness less than 0.05mm. This system does not affect the lifetime of mold;

.Self-lock System

International advanced bi-awls fixed orientation self-locked structure has been adopted.

.Cooling System

All the water Channels in the mold’s each inner part, which make the cycle time short enough. And all the cooling channels have been specially treated to prevent them from jam;

.Heating System

Double Heating System can ensure that the impact of heating is good and quality control is credible. The Heating Band unit makes nozzles be with invariable temperature. The Heater Unit is used to heat the hot runner plate with long using life and powerful heating capacity.

.Hot Runner System

The perform mold adopt Pin-valve type Hot Runner System, such hot runner system can reduce mold’s each part’s wear & tear and maintenance cost, and also save 10%~15% electric energy;

.Hydraulic Ejecting System

The perform-doffing success ratio has achieved firm endurance and the whole perform ejecting process will become much quieter.

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: How do H13 mould steel heat treatment

- 1. Preliminary heat treatment in the market supply of H13 steel and die steel billet, in the steel mills have prepared annealing heat treatment, ensure the good metallurgical structure, proper hardness, good processability, and no longer annealing. But factory to change after forging has destroyed the original organization and performance, stress, increased the forging must be annealed. Isothermal spheroidizing annealing process for: 860 ~ 890 ℃ heat insulating 2 h, cooling to 740 ~ 760 ℃ isothermal 4 h, furnace cooling to about 500 ℃.

- Q: What are the molding methods of plastic molding mould?

- Plastic blow molding mold: is used for molding plastic hollow container class products (such as beverage bottle, cosmetic products all kinds of packaging containers) of a mold, blow moulding main form according to the process principle of extrusion blow molding hollow molding, injection molding, main form according to the process principle of extrusion blow molding hollow molding, injection blow molding hollow molding, injection stretch blow molding hollow molding (commonly known as "note" blowing), multi-story hollow blow molding, sheet molding hollow molding, etc. The equipment of hollow product blowing and molding is usually called plastic blow molding machine, and blow molding is applied only to the production of hot plastic variety products. The structure of blowing mold is relatively simple, and the materials used are made of more carbon.

- Q: How to calculate the cost of plastic mould?

- Mold calculation cost is actually very simple, mold steel and toll fee counting and personnel salary, these are the main three cost, mould quotation I do work more than ten years, the products are numerous, I have a look at any plastic products will be able to know the price, if I can help you have drawings or samples

- Q: What is a mold?What is it mainly used for

- Are the molds hard to learn? As long as you are not a complete idiot. Anyone can learn. Of course, is sure need time, anyone don't 3-5 years of time, you are difficult to achieve a master level, of course I said is plastic mold, metal mold is faster, because their forming conditions of completely different. And basic didn't also spoke on the first floor. You don't understand, can learn the process of learning, who is on the first floor said the things you want to learn, of course there are other. And future, that is to go on their own, a teacher can be in 4000 in suzhou, and hardware module can also be in 3000 or so. All I said is fitter oh, of course design will be a little bit higher.

- Q: What is the design philosophy of the mould?

- The domestic development situation of facing the 21st century, the enterprise to adapt to the development of market economy, as the national support industry of the automobile industry will increase production of light, the micro, cars, thus puts forward higher requirements on the precision of the die forgings. In the process of production, improving die life is a complex and comprehensive problem. All forging technology, especially the net net shape and approximate shape processing technology, to a large extent depends on the precision and quality, mould depends on the skill level of the mould. Mould technology is reflected in die design and manufacturing, and die life is related to the use of the process. ? Is of great economic benefit to improve die life, generally in the trial production mold tooling costs accounted for about 25% of the cost of production, and finalize the design production is only 10%.

- Q: What is the difference between mould injection and blow molding?

- Injection molding is used to make the mold and then inject the plastic into the mould. Blow molding is used to make a good plastic moulds after heating softening in the embryo, the embryo within the join high pressure air, thinning of the tensile softening of the embryo, formation and mould the same products. Injection molding can make a very complex plastic product, and you can say what shape you want to make. Blow molding can only make hollow products, such as drink bottles and some tool boxes. The moulds are very expensive and the processing is more expensive. Blow molding and processing are cheaper

- Q: What is the difference between a large water inlet and a thin nozzle?

- The difference between a large water inlet and a thin water nozzle: 1, from the entrance of the entrance to the glue mouth: one is the point gate (directly from the product to the glue) usually called the thin nozzle mold; One is from the side into the glue, gate is relatively big usually call gate mould (but sometimes think products turn into the glue need will do fine shuikou gate into the glue, structure and three board mould) Different from the structure of the mould: the two plates are usually called the large water port molds. There are two kinds of thin water mouth mould and thin water mouth mould.

- Q: Because many of the molds in our factory have batch sewing, who can tell me how to fix the batch seam. Because I don't understand, but I'm going to learn, so I want to know in advance, thank you very much!

- In the case of the building Lord, all the moulds have a lot of wind, which is that the injection molding machine is not enough

- Q: How do you play the continuous stretch mold

- It is almost impossible to form a single shape. The concrete steps are not clear, but the rough step is to pull the outside circle first, then take the small circle and take shape.

- Q: Do machine parts need to be moulds?

- The parts of the machine are not required to open the die.I hope my answer will help you.

Send your message to us

Plastic Injection Mould Multi-cavities Hot Runner Plastic PET Perform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords