PET Preform Mould PET Preform Injection Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

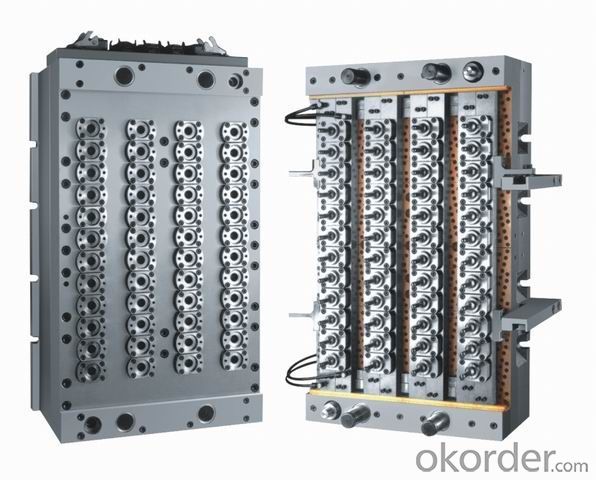

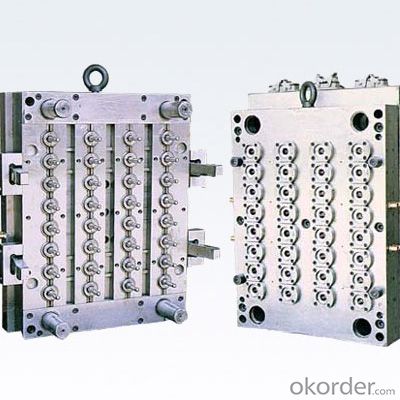

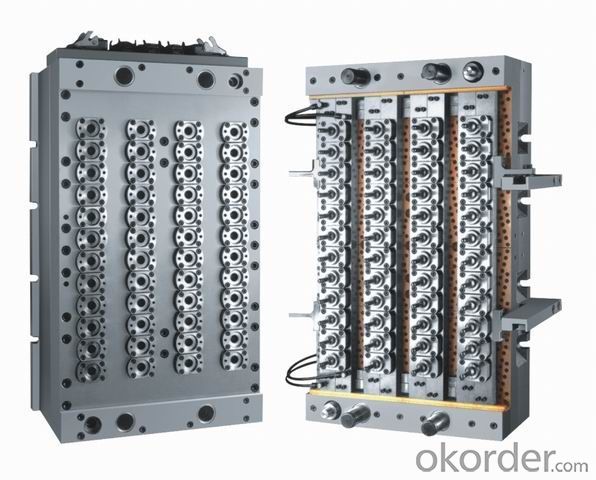

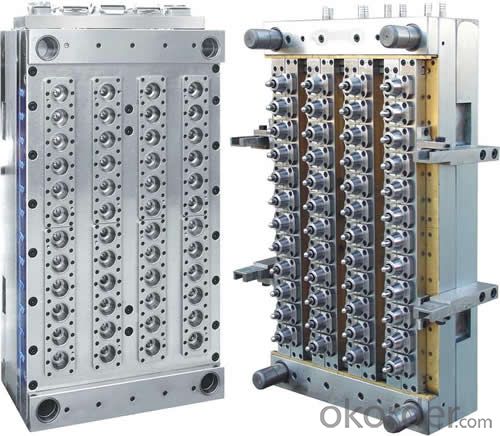

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

.Design to production of mold, 100% made in Taiwan.

. The SGS RoHS Certification Mark demonstrates our commitment to quality and achieving consistent production.

. Excellent in interchangeable cores molds design.

. Surface finish with high gloss polishing.

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

. Can supply with both Mold & Molded parts

. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: How does the concave and convex mold in the mold differentiate

- Upstairs said is right, for your own sake don't tube concave and convex, easy to use dynamic model set mode to distinguish, according to the dynamic set of injection molding machine templates, fixed on the dynamic template is called dynamic model, set the template name is fixed on the mold

- Q: What is the role of the guide in the mould

- The most common guide is the guide. In addition, large molds may set up the guide, and the microdie may set up the catheter, which is the same as the guide.

- Q: What is the difference between the p20 mould steel and the nak80-b mould steel

- It's completely different, the composition is different, P20 is 3Cr2Mo, and NAK80 is 10Ni3MnCuAl

- Q: What are the types of molds?

- From different materials: plastic die, metal stamping die, forging die, metal die casting mould, ceramic die, glass mold, glass steel mould etc. There are many types of each.

- Q: What are the molding methods of plastic molding mould?

- Injection molding; Plastic extruding and forming; Plastic compression molding; Plastic blow molding; Plastic heat forming; That's all I know. I hope it helps. The specific thing, can go online check!

- Q: How many types of molds? Please help me out!

- The mold can be divided into metal mould and non-metallic mould according to the material that is formed. The metal mould is divided into: casting mould (non-ferrous metal casting, steel casting) and forging die etc. Non-metallic mold is also divided into: plastic mould and inorganic non-metallic mould. And according to the material of the mould itself, the mold can be divided into: sand mold, metal mould, vacuum mold, paraffin mold and so on. With the rapid development of polymer plastics, plastic mould is closely related to people's life. Plastic mould can be divided into: injection molding mold, extrusion molding mold, gas auxiliary molding mould and so on.

- Q: What is suitable for moulding steel

- Cold rolled molds include cold die, wire drawing die, drawing die, press die, thread rolling die, roller plate, cold press and cold extrusion die. Cold work die steel, according to the working conditions, and should have high hardness, strength, abrasion resistance and sufficient toughness, and high hardenability, hardenability and other process performance. Used for such purposes of alloy tool steel is generally belongs to the high carbon alloy steel, carbon mass fraction 0.80%, chromium is one of the important alloy elements such as steel, its mass fraction is usually not more than 5%. But for some high requirement of abrasion resistance, small deformation of mould steel after quenching, high chromium mass fraction is 13%, and in order to form a large number of carbide, carbon in steel quality score is high, up to 2.0% ~ 2.3%. The carbon content of the cold steel mold is high, and its organization is mostly in the form of a di-di-steel or lystenoid steel. Commonly used steel types have high carbon low alloy steel, high carbon high chromium steel, chrome molybdenum steel, medium carbon chromium tungsten steel, etc.

- Q: Because many of the molds in our factory have batch sewing, who can tell me how to fix the batch seam. Because I don't understand, but I'm going to learn, so I want to know in advance, thank you very much!

- If solve the above problem is mould itself reason, please use red lead to mold fitting well, the original poster check mold in touch wear, wear a location, see if cooperate in place.

- Q: Why are the stamping molds wrinkling?

- The pressure side is small or the clearance is large, please check carefully.

- Q: What is the mold major

- Industrial production is used for molding, blowing, extrusion, die-casting or forging, metallurgy, stamping and stretching, etc., to obtain the various molds and tools of the required products. In short, the mold is a tool for molding objects, which are made of different parts, and different parts are made of different parts. It mainly USES the physical state of the forming material to realize the processing of the physical appearance.

Send your message to us

PET Preform Mould PET Preform Injection Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords