Preform Injection Molding PET Preform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

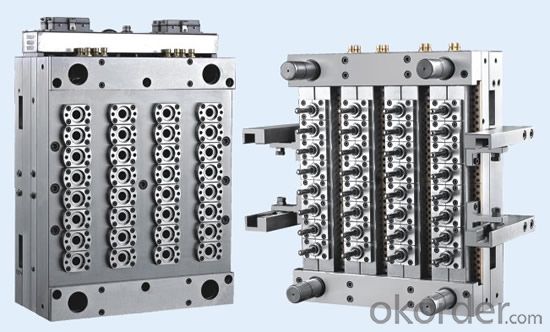

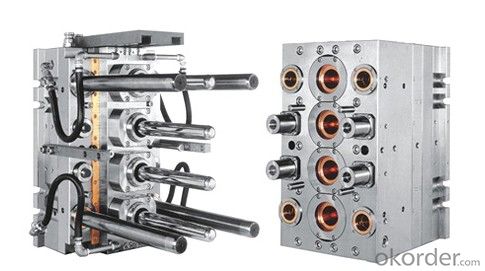

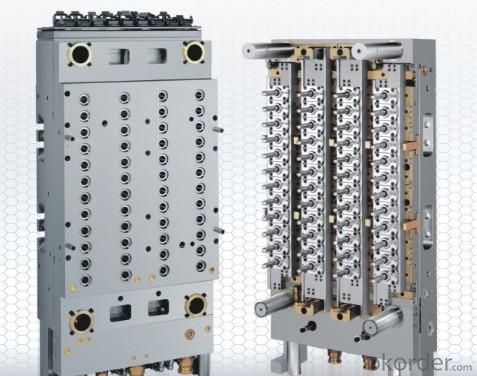

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

PET Preform Injection Molding from 1-cavity for wide mouth jar and gallon bottle perform up to 72-carrow neck perform mold; Tube blank is designed with the help of computer, which surely contributes to the increasing of yield of bottle;

Employed internationally advanced two-step dual taper locating technology. Each cavity self-locks independently to ensure low decentration of product;

Core and cavity are made of special mold steel after preheating treatment in the original factory in Sweden. Individual tempera-ture control of each cavity;

Lip cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The excellent hot runner design assures uniform heating and improves greatly of the plastic product quality;

No cutting of gate is employed to reduce the labor intensity;

Standard inter-changeable mold components;

The life of mold is more than 3 million times.

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: What effect is the flange of the die

- Flanges are concentric with the jw, flanged, and the nozzle of the injection-molding machine, the flanged design corresponds to the size of the machine. 1, flanges, or flanged flanges or flanges. The flange is the part of the pipe that is connected to the pipe and is used for the connection between the end of the pipe. Also useful for the flange of the equipment import and export, for the connection between two devices, such as reducer flanges. Flange connection or flanged joint, which refers to the disconnection of a combination of flange, gasket and bolt. The pipe flanged flanged is a fitting flange for the piping device, which is used to refer to the equipment's import and export flanges. There are holes in the flanges, and bolts make two flanges. The flange is sealed with gasket.

- Q: How to choose the injection molding machine when the mould design

- If you choose me as a manufacturer of injection molding machines, we will do our best to help you design the equipment you want

- Q: What courses are required to learn the UG mould design?

- UG 3 d modelling; 2. Assembly drawings; 3. Engineering drawing; 4, learn about the battlefield copy board; Understand reverse engineering; Mould structure and processing technology; CAD 2 design; Graph printing; Structural design; IGS mend the broken face; Product analysis; Coordinate setting; Part PARP method; Size block method; The parting face is created, sliding block, diagonal, and inlaid design. 16. Copper down the male; How to solve the inseparable method; Knowledge of 2D molds; Basic theory knowledge and processing technology of CAD mould design; 20. CAD position; The process and method of the molds. Design of the thimble; Water design; Design of inserts; Mold and product labeling; Line cut; The principle and method of designing the design of a cavity, row, slant, thrust block, front die, and former die line in the factory design example

- Q: What are the molding methods of plastic molding mould?

- Plastic injection mould, it mainly is the most widely used in the production of thermoplastic plastic products of a forming mould, plastic injection molding mold corresponding processing equipment is plastic injection mold and the corresponding equipment is plastic injection moulding machine, plastic in the first place in the bottom of the injection machine heating cylinder heated melting, and then in the injection machine screw or plunger, driven by the injection machine nozzle and mould gating system into the mold cavity, cooling hardening molding, plastic mold release products. Its structure is usually composed of forming parts, pouring system, guiding parts, launching mechanism, tempering system, exhaust system and supporting parts. The manufacturing materials are usually made of plastic mould steel modules, which are mainly made of carbon structural steel, carbon tool steel, alloy tool steels, high speed steel etc. Injection molding processing methods are usually only applicable to hot plastic products production, with the production of injection molding plastic products is very broad, from daily necessities of life to all kinds of complicated mechanical, electrical, vehicle parts are made of injection molding, it is the most widely used in the production of plastic products of a processing method.

- Q: Injection mold. What does the soft mold mean? What's the difference between a quick one?

- A soft die is a concept that is relative to a hard mold. In the process of component design generally need to verify the design of plastic parts is reasonable, can meet the requirements of the assembly and product design changes may need to be kept. This way, we need to open a sample molds before mass production. Until the design is no longer changed, the initial mass production is limited to a single hole of capacity, which requires a large cavity. In the comparison between soft and hard models, the soft mold is not as good as the hard mold (which is the die life), except for the steel choice. What do you mean by a quick form that you don't understand? Is it a plastic block? If this is the case, then a quick form is not needed, but only a few or dozens of samples can be done, and the cost is high. The average life span of a soft mold is no less than 50,000 modules, even higher. If batch not small plastic parts, often one a hole to use soft model completely can satisfy capacity.

- Q: The performance requirement of die steel

- Wear resistance The most important factor in determining the life span of die is the wearability of die materials. The mold is subjected to considerable stress and friction at work, and it is required that the mould can maintain its dimension accuracy under intense friction. The wear and tear of the mould are mainly of mechanical wear, oxidation and wear and tear. In order to improve the wear resistance of steel, will be die steel with high hardness, and to ensure that the carbide in steel or other composition, morphology and distribution of hardening phase is quite reasonable. Serving for overloading, high-speed wear under the condition of the mold, the steel surface to form a thin and dense oxide film with good sex of adhesion, lubrication, reducing between die and workpiece stick bite, welding, melting and wear, and can reduce the mold surface oxidation caused by oxidation wear and tear. So the working conditions of the mould have a large effect on the wear and tear of steel. The test method of abrasion resistance can be used to measure the relative wear-resisting index, as a parameter of the resistance level of different chemical constituents and tissues. In order to present the life of the pre-burring height, it reflects the wear-resisting level of various kinds of steel. The test was based on Cr12MoV steel.

- Q: What is the difference between imported mold and domestic steel

- Look not to come out from the appearance, warranty can be divided, but did not rule out the JS, use should be able to separate, but does not rule out the use of high quality domestic steel service life is better than imported steel and when selling imported steel.

- Q: How to calculate the weight of die steel?

- Calculated in accordance with the relevant formula began below: volume = length x width x height (thick) weight x = weight proportion: the steel plate you use = 80 cm long = 50 cm wide = 25 cm thick Thick volume = length x width x = 80 * 50 * 25 = 100000 (cm) square weight = weight proportion of x = 100000 * 7.85 = 785000 grams The weight of the steel plate is: 785000 g = 785 kg

- Q: What are the advantages of using a hot runner?

- Mould at first using cold gate type products take material valve, sometimes forgotten to disc molding material not to say every mould produce secondary material is the material valve, hot runner after solved this problem, reduce secondary molding material directly, reduce labor workers parts, but that time has its drawbacks as well as the hot runner is uncontrolled, namely can't control the quantity of each point into the glue, along with the technical improvement on the current hot runner is mostly in the use of needle valve type, Kong Shi time controller is used to control each needle valve into the adhesive time for technology transfer machine save trouble is much,,,, adopt to adopt

- Q: How do you play the continuous stretch mold

- It is almost impossible to form a single shape. The concrete steps are not clear, but the rough step is to pull the outside circle first, then take the small circle and take shape.

Send your message to us

Preform Injection Molding PET Preform Mould

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches