PET Preform Mould Injection Preform Mold

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

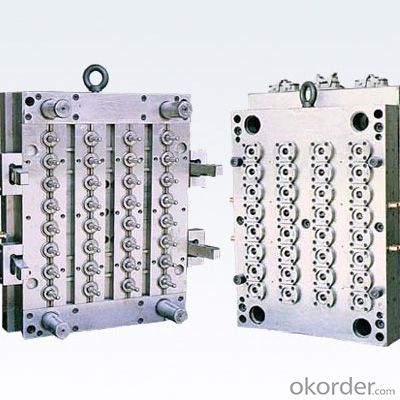

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

.Mould structure

Advanced structure is designed to improve rate of finished products;Two-step double taper locating technology;The each cavity is self locked independently with the core.The off-center adjustment system make the perform thickness error less than 0.05mm.Bottleneck is adopted International Screw thread standard, No cutting of gate to reduce the labor intensity

. Material of steel

Cavity and core use stainless steel 2316 with fine polishing,high hardness to get mold's high precision and good quality. mechanical treatment cavity and core to prolong service life,nitrogen treatment with neck screw.with fitly operation,guarantee Long using life over 2 million shots of injection cycle

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

PET preform injection mould with normal long tail availabe.

short tail mould available.

valve gate without tail mould availabe.

4~48 cavity mould as customized.

23 years experience of preform mold specialized manufacture.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q: What is the cooling system of the mold

- Exactly, the thermostat system of the mold should be called. Cooling, it's just part of this constant temperature, and the other part is insulation. In the process of injection molding, according to the material, the requirements for the mould temperature are different. For example, PP material, the temperature requirement of the mold is not high, the circulating water cooling is ok, it is ok to keep room temperature. But some materials, such as PC, require that the temperature of the die need to be kept above 80 degrees, which requires the temperature of the temperature machine to warm up the water. There are some special materials such as PPS (PPS) to demand a higher mold temperature above 150 degrees, also need the oil temperature machine or electric heating rod to heat the mold. Thermostatic system generally is in the mold cavities internal hole, forming one or more than one closed loop pipes, hoses, a into a mission of water flow in the pipeline, to keep the temperature of the mold temperature is constant. This is the die water. The other is the heating rod, which is inserted into the molds of the molds to keep the temperature above 100 degrees. It should be said that most of the moulds should be made by water, and no water will affect the life of the mold, mainly by the effect of injection molding process.

- Q: What do you mean by plastic mold injection molding? What's the use?

- The assurance means a fixed pressure on the material in the mold. Because the plastic in the cooling process has the effect of heat bilges cold shrink, especially larger plastic shrinkage, heat bilges cold shrink is very obvious, so when we give the material after a fixed pressure, plastic shrinkage during the cooling process, the mold melt pressure began to decline, with the holding role, and the hydraulic system will automatically forward pressure, progress in the back of the material, added the contraction of the melt front, thus forming prevent products caused by shrinkage deformation. Adjust the pressure of pressure and the time of holding pressure, adjust the product defects such as the flying side, fuse connection and shrinkage mark.

- Q: Injection mold. What does the soft mold mean? What's the difference between a quick one?

- A soft die is a concept that is relative to a hard mold. In the process of component design generally need to verify the design of plastic parts is reasonable, can meet the requirements of the assembly and product design changes may need to be kept. This way, we need to open a sample molds before mass production. Until the design is no longer changed, the initial mass production is limited to a single hole of capacity, which requires a large cavity. In the comparison between soft and hard models, the soft mold is not as good as the hard mold (which is the die life), except for the steel choice. What do you mean by a quick form that you don't understand? Is it a plastic block? If this is the case, then a quick form is not needed, but only a few or dozens of samples can be done, and the cost is high. The average life span of a soft mold is no less than 50,000 modules, even higher. If batch not small plastic parts, often one a hole to use soft model completely can satisfy capacity.

- Q: The effect of mould preheating and several methods of preheating

- Natural (coal) gas heating: a widely used method. Applicable to different mould shapes. The heater is made of pipes, and there are many small holes in it, and the gas is ejected and the size of the fire can adjust the air valve to achieve it. Clean without pollution, can be heated locally. The disadvantage is that it is controlled by people, and it is easy to burn the mold.

- Q: How is the die in the manufacturing industry

- According to the specific use time of the mould, such as one year can be used in manufacturing expense account. You may enter a long-term deferred expense account for more than one year.

- Q: What certificate does the mold major need to take an examination?

- (1) AutoCAD is a software that is easy to learn and can be used as a basis for CAD, which is software for almost everyone in the industry. This is a two-dimensional software that doesn't have to learn its so-called 3-dimensional function because it's basically not used for 3-d purposes. Once you've learned the software, you can stay at this stage and learn one of the two 3-dimensional software. (2) the Pro/E (weak) design function, programming (3) the UG (design aspects as Pro/E, but programming function is stronger) which of the two 3 d software to learn. If you want to improve your mold design ability, consider taking part in a training session. After training, you will be able to get a real job.

- Q: What does the mold slow wire do

- Is walking wire edm wire cutting is a kind of English abbreviations (WEDM LS) is the use of continuous moving fine wire electrode (called wire electrode), pulsed spark discharge of artifact removal in metal, cutting shape. It is mainly used for processing of complex shape and small precision of workpiece, according to different wire electrode material (one is molybdenum wire, one is the copper wire), wire cutting machine tool is usually divided into two kinds: one kind is walking wire (wire electrode is copper wire), wire electrode for low-speed one-way movement, the general wire walking speed is lower than 0.2 m/s, the accuracy of 0.001 mm, and close to grinding surface quality level. The electrode filament is not used after discharge, the job is smooth, uniform, jitter and the quality of processing is better. Moreover, advanced power technology is adopted to achieve high speed processing, with maximum productivity of 350mm2 / min

- Q: What is a mold bite

- Make pattern, can make the surface of product surface and cavity surface can hold a small amount of air, do not form vacuum adsorption, make it easy to get out. Anti-skid, anti-roll, good handle. To make hemp or subsurface, prevent light reflection, eliminate eye strain and so on.

- Q: What is the difference between a mold and a handboard?

- Although there are so many differences between planks and mould, but they still have contact, generally use hand-board model to the customer to confirm the shape first, confirmed to open mold production. The cost of many physical molds is generally high, with large molds valued at 100,000 or even millions, especially in the medical industry. If there is a structural unsound or other problem in the process of installing the die, it will be very large. The handboard model can solve the problem of this loss, reducing the risk of making physical models.

- Q: What are the career prospects of the mould profession

- It is understood that at present China mold enterprise is generally met a talent shortage problem, talent shortage has become the mold technology to further improve the bottleneck of further development, mould industry. The salary of mould personnel rises. Due to many enterprises difficult to recruit skilled senior technicians, lead to these people pay tends to rise, such as professional mold design of average monthly salary of 3000 yuan, nc 3500 yuan a month, familiar with design, processing, modelling the whole operation process of senior workers more than 5000 yuan a month, and the skills a good talent over ten thousand yuan a month is not unusual.

Send your message to us

PET Preform Mould Injection Preform Mold

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords