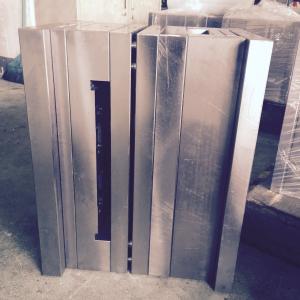

Standard Mould Base/Plastic Injection mould base

- Loading Port:

- Ningbo

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

This product USES S50C material.Accessories are all made of standard guide pin guide bush.The thickness tolerance are processed according to the requirements of 0.00 to 0.02.High surface finish and roughness of standard.Heat resistance and corrosion resistance is very strong, It is used in plastic mold development and manufacturing,composed of various steel plate with parts,It is a complete set of the mould size to make it easier for mold into the injection molding machine installation.specific parameters according to customer requirements.

Specifications

mold base, LKM standard mold base, HASCO standard mold base, DME standard mold base, LKM mold base, HASCO mold base

mold base, LKM standard mold base, HASCO standard mold base, DME standard mold base, LKM mold base, HASCO mold base,mould base, LKM standard mould base, HASCO standard mould base, DME standard mould base, LKM mould base, HASCO mould base

What We Do

Plastic Injection molds. tools making Clear acrylic Injection molding Prototyping and model making Plastic Printing & Welding & Assembly Product 2D&3D design.Reverse-engineering.etc

What We Believe

High quality is the only factor we consider Innovation reduces the cost,increase capacity One-stop solution assures the satisfaction of customer.

We expert in development and fabrication of various high quality moulds with advanced technology and tooling equipments.

High-speed CNC machine Engraving machine Mirror EDM machine Milling and Grinding machine Slow W-EDM machine

We provide one-stop solution from drawings design to final parts

PMMA.ABS.PP.PC.PS.PBT.etc Injection machines equipped with robots Feeders & Dryers. Temp. controlers Assembly line with silk-screen & painting

Advanced CAD and CAM software is adopted in the tool making process.Operated by our experienced engineers.

Moldflow Pro-Engineer Solidworks Unigraphic Auto-CAD

Pictures of the mould base:

- Q: What is the role of the guide in the mould

- The most common guide is the guide. In addition, large molds may set up the guide, and the microdie may set up the catheter, which is the same as the guide.

- Q: What is the cooling system of the mold

- It is in the core that makes the channel for cooling water flow. The effect is to ensure that the mould has a reasonable temperature balance in the process of production.

- Q: Is the slanting and shoveling chicken in the mold the same thing, shoveling the chicken? Where is it used?

- The same thing, different calling, is used on the top of the slider to balance the lateral forces

- Q: What courses are required to learn the UG mould design?

- Software UG mold design and processing technology of mold manufacturing, etc., to learn the software Suggestions to learn mould theory knowledge at the same time, access to practice is the best, the UG is just a kind of tool of mold design, don't understand the mold design theory and the practice of knowledge, the design is difficult to learn, suggest to buy books on mold design technical guidance.

- Q: Injection mold. What does the soft mold mean? What's the difference between a quick one?

- A soft die is a concept that is relative to a hard mold. In the process of component design generally need to verify the design of plastic parts is reasonable, can meet the requirements of the assembly and product design changes may need to be kept. This way, we need to open a sample molds before mass production. Until the design is no longer changed, the initial mass production is limited to a single hole of capacity, which requires a large cavity. In the comparison between soft and hard models, the soft mold is not as good as the hard mold (which is the die life), except for the steel choice. What do you mean by a quick form that you don't understand? Is it a plastic block? If this is the case, then a quick form is not needed, but only a few or dozens of samples can be done, and the cost is high. The average life span of a soft mold is no less than 50,000 modules, even higher. If batch not small plastic parts, often one a hole to use soft model completely can satisfy capacity.

- Q: How many products can a mold make?

- Simple molds are less, a good order of hundreds of millions of molds can be done, but some parts need to be fixed regularly

- Q: What is the manufacturing of mould materials

- You're talking about the industry that makes moulds. It is the metallurgical industry that makes mould material. From steelmaking to forging and rolling, it also belongs to heavy industry.Belong to die design, consider the choice of suitable material.

- Q: What are the career prospects of the mould profession

- Mold professional prospect is good, although in recent years many learn this, but the market is only lack of talent, to shine on you, to learn, this is a good iron rice bowl, is willing to endure hardship, I also learn the mould... Oh, we have time to communicate

- Q: The wall thickness of the die is affected by the plastic parts

- For thermoplastic materials, the cooling time is added For thermosetting materials, solidification is not complete.

- Q: How do you buy the die?

- The low value of the item can be used at the expense of the account When buying Borrowing: low value of consumption Borrow: the tax that should pay the tax - value added tax Credit: bank deposits When using Borrowing: manufacturing expense - low value consumables amortization Loan: low value consumables Of course, If the amount is large, it can be amortized.

Send your message to us

Standard Mould Base/Plastic Injection mould base

- Loading Port:

- Ningbo

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords